Stainless steel wire strength detection equipment based on elasticity testing mechanism

A technique of elasticity testing and strength testing, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve problems such as unfavorable use, uneven force, inability to adjust, etc., to extend service life , Avoid high temperature, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

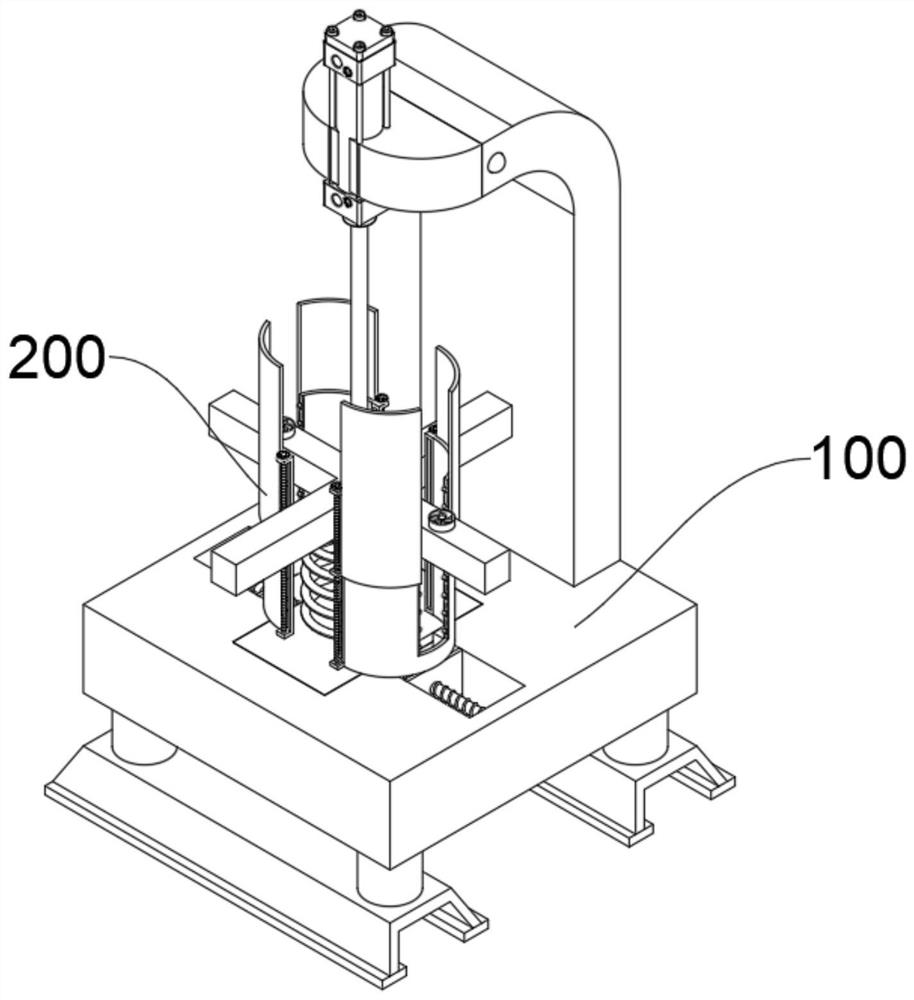

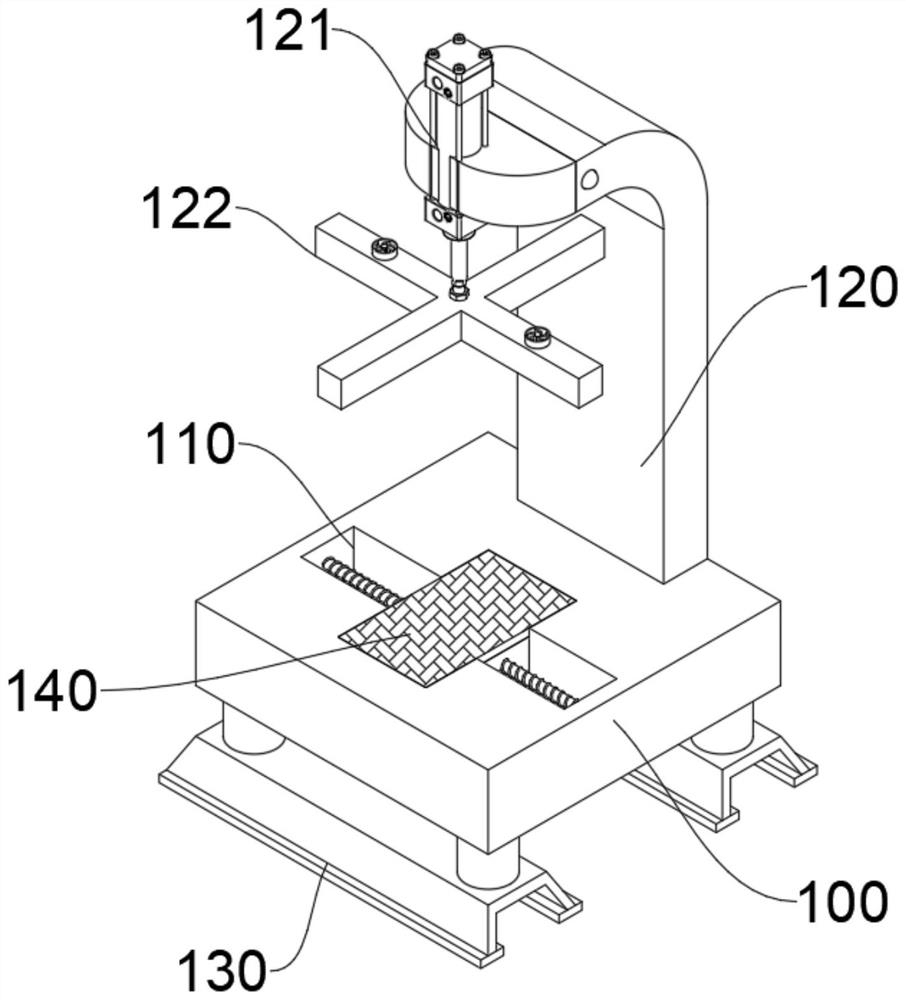

[0038] see Figure 1-Figure 4 As shown, the present embodiment provides a stainless steel wire strength detection device based on an elastic testing mechanism, including at least:

[0039] Base plate 100, base plate 100 top edge is provided with support plate 120, and support plate 120 is " L " shape, and support plate 120 end is provided with cylinder 121, and cylinder 121 piston rod end is connected with extruding plate 122, connects cylinder 121 Turn on the power to make it work, and the piston rod of the cylinder 121 slides up and down, which can drive the extrusion plate 122 to move up and down, so as to facilitate the subsequent extrusion of the spring stainless steel wire for strength and elasticity detection. It is a device or device that can sense the pressure signal and convert the pressure signal into an available output electrical signal according to certain rules. It can receive the elastic force brought by the compression of the spring stainless steel wire and ju...

Embodiment 2

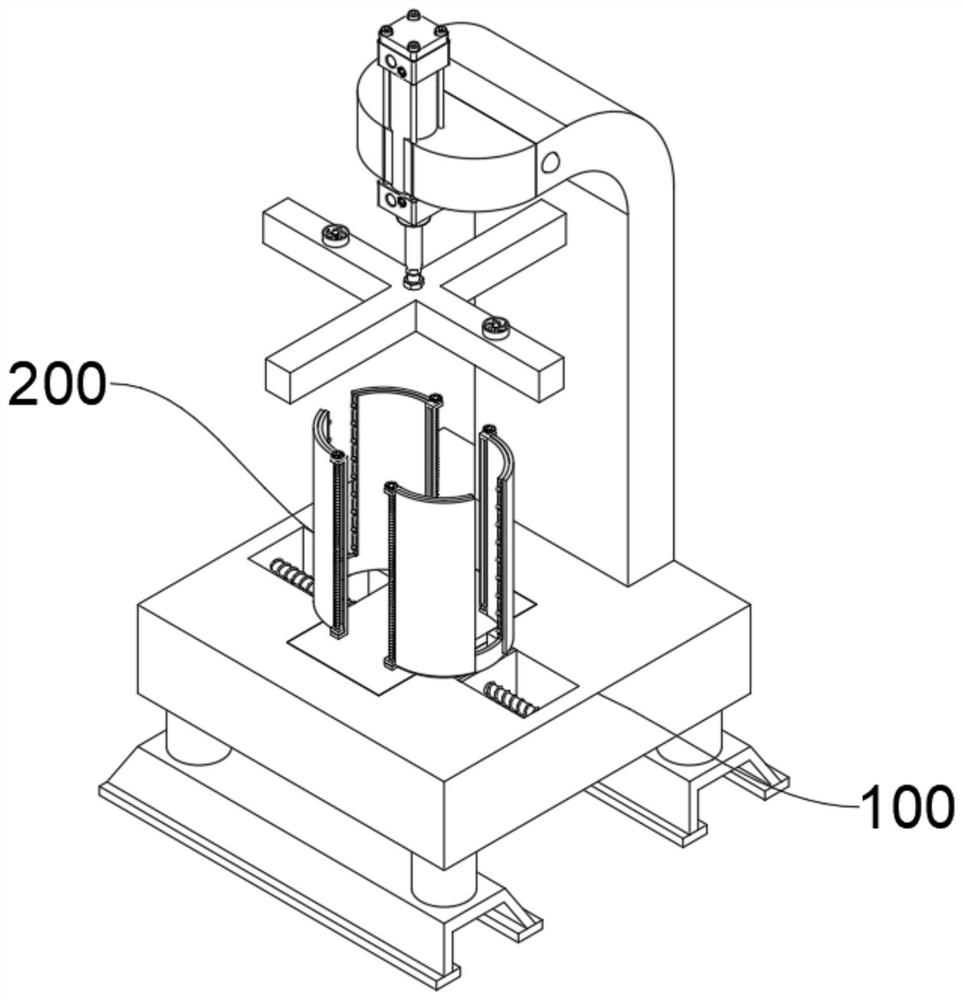

[0044] In order to adjust the limit range according to the size of the spring stainless steel wire, to ensure that the periphery of the spring stainless steel wire is limited by the limit arc plate 210, the difference between this embodiment and embodiment 1 is that please refer to Figure 5 shown, where:

[0045] There are two symmetrical moving slots 110 on the top of the bottom plate 100, the pressure sensor 140 is located between the two moving slots 110, the moving screw 111 rotates inside the moving slot 110, the bottom of the limit arc plate 210 is provided with a moving plate 220, the moving plate 220 is threadedly connected with the outer wall of the moving screw rod 111, so that the two moving screw rods 111 can be rotated simultaneously, so that the surface of the moving plate 220 at the bottom of the two limiting arc plates 210 slides along the screw thread on the outer wall of the moving screw rod 111, driving two The limit arc plate 210 gathers inward or spreads ...

Embodiment 3

[0048] In order to prevent the adjustment plate 231 from rotating with the adjustment screw 2121 and make the movable arc plate 230 slide up and down more stably, the difference between this embodiment and Embodiment 1 is that please refer to Image 6 shown, where:

[0049] The side wall of the adjustment plate 231 is provided with a positioning block 232, and the inner wall of the lifting plate 212 is provided with a positioning groove 2123. The positioning block 232 is compatible with the inside of the positioning groove 2123. When the outer wall of the adjustment screw 2121 slides up and down, the positioning block 232 is driven to slide inside the positioning groove 2123, and the direction in which the adjustment plate 231 slides can be limited to prevent the adjustment plate 231 from rotating with the adjustment screw 2121, so that the movable arc plate 230 moves up and down. Slide is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com