A large-span curtain wall composite structure and its installation method

A combined structure and long-span technology, applied to walls, building components, building structures, etc., can solve problems such as uncoordinated, uneconomical, and unable to meet force requirements, and achieve the effect of avoiding tilting and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

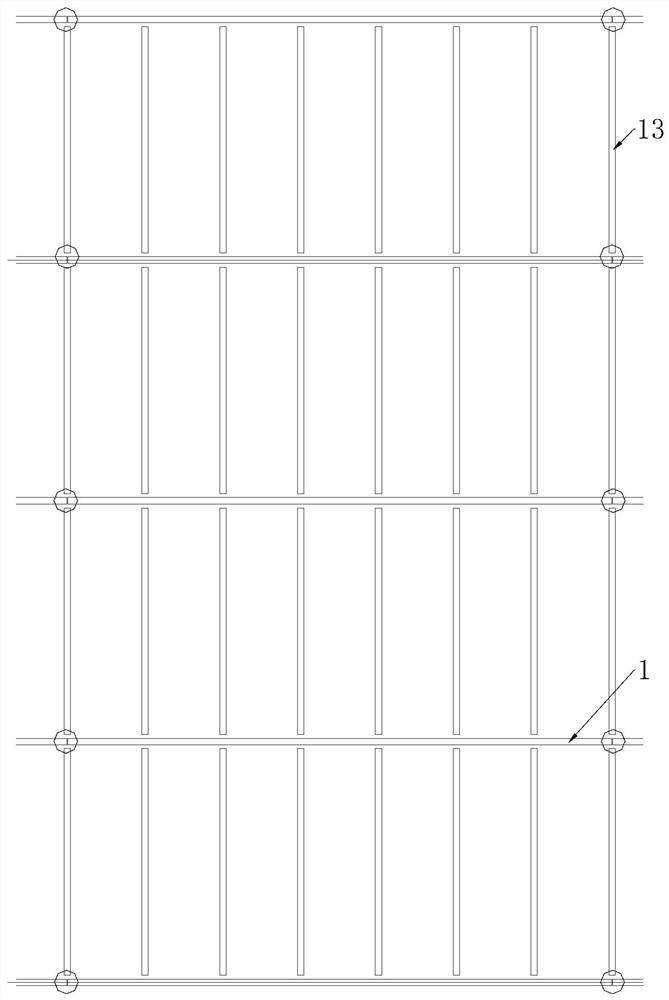

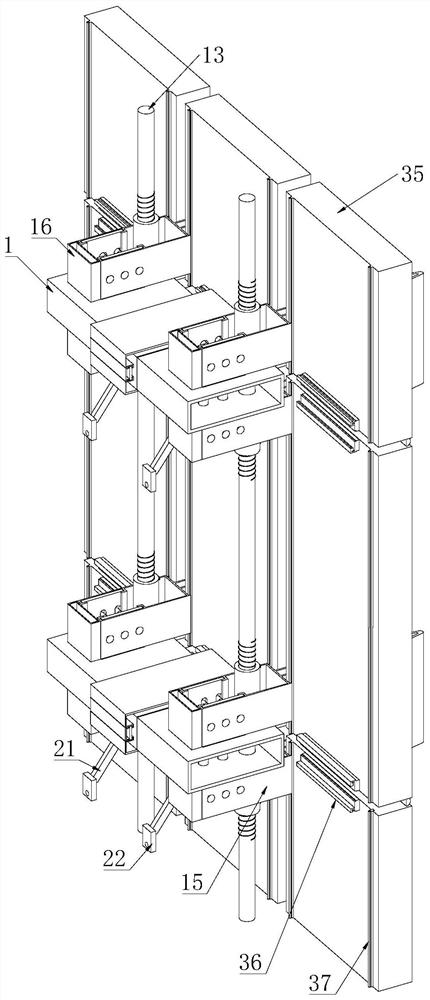

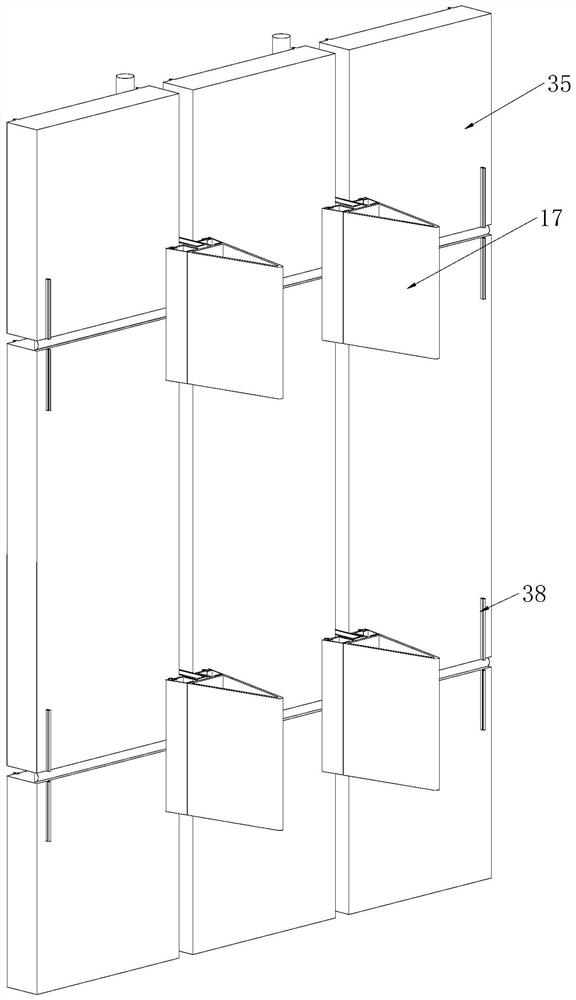

[0050] see Figure 1-17 , a large-span curtain wall composite structure, comprising a large steel beam 1 arranged on the wall and a glass block 35 arranged on the steel beam 1, and the top and bottom sides of the steel beam 1 are provided with tie rod pairs at equal intervals. 2 and multiple groups of bolt pairs of holes 3, one tie rod pair of holes 2 corresponds to a group of bolt pairs of holes 3, the side of the steel beam 1 close to the wall is provided with a first wire hole 4, and the steel beam 1 faces away from the wall One side is provided with a bending steel plate 5 corresponding to the first wire hole 4, the first wire hole 4 and the bending steel plate 5 are alternately distributed with the tie rod pair hole 2 and the bolt pair hole 3. A support connection mechanism for connecting the upper and lower steel beams 1 is arranged through the pair of holes 2 of the tie rods at equal intervals, and an auxiliary fixing mechanism for fixing the two sides of the glass bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com