Gold stamping machine achieving pattern intaglio-relief printing and gold stamping integrated forming

A gold-integrated, bronzing machine technology, applied in the field of bronzing machines, can solve the problems of reducing processing efficiency, dismantling many structures, reducing the disassembly efficiency of staff, etc., to achieve the effect of improving the efficiency of disassembly and replacement, and improving the efficiency of bronzing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

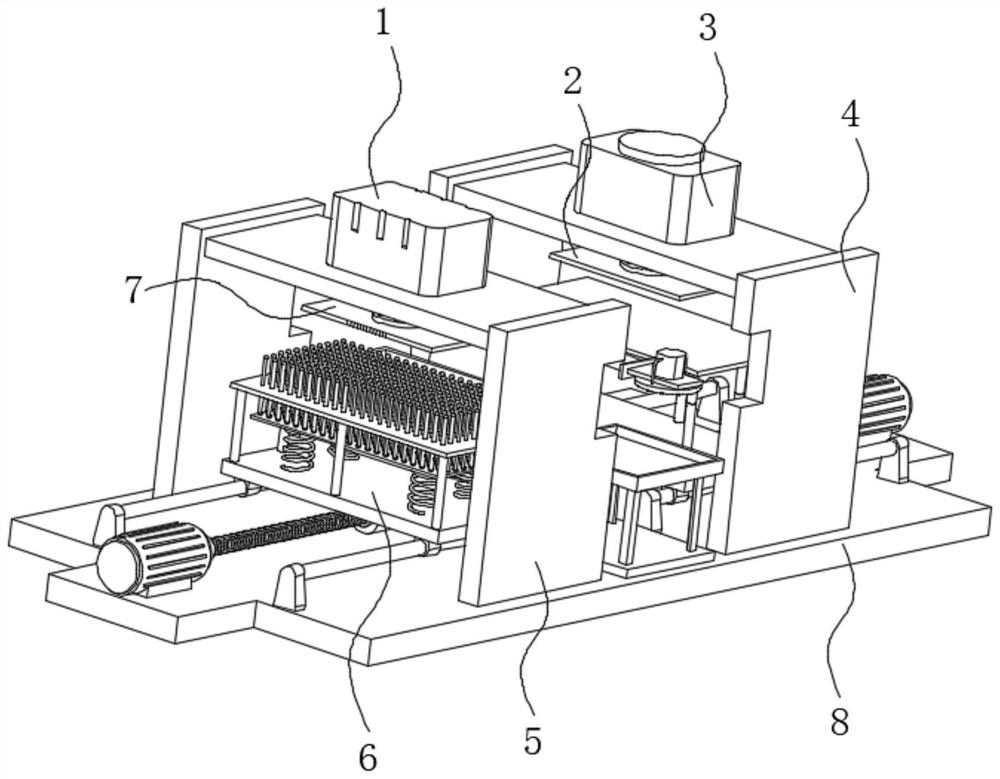

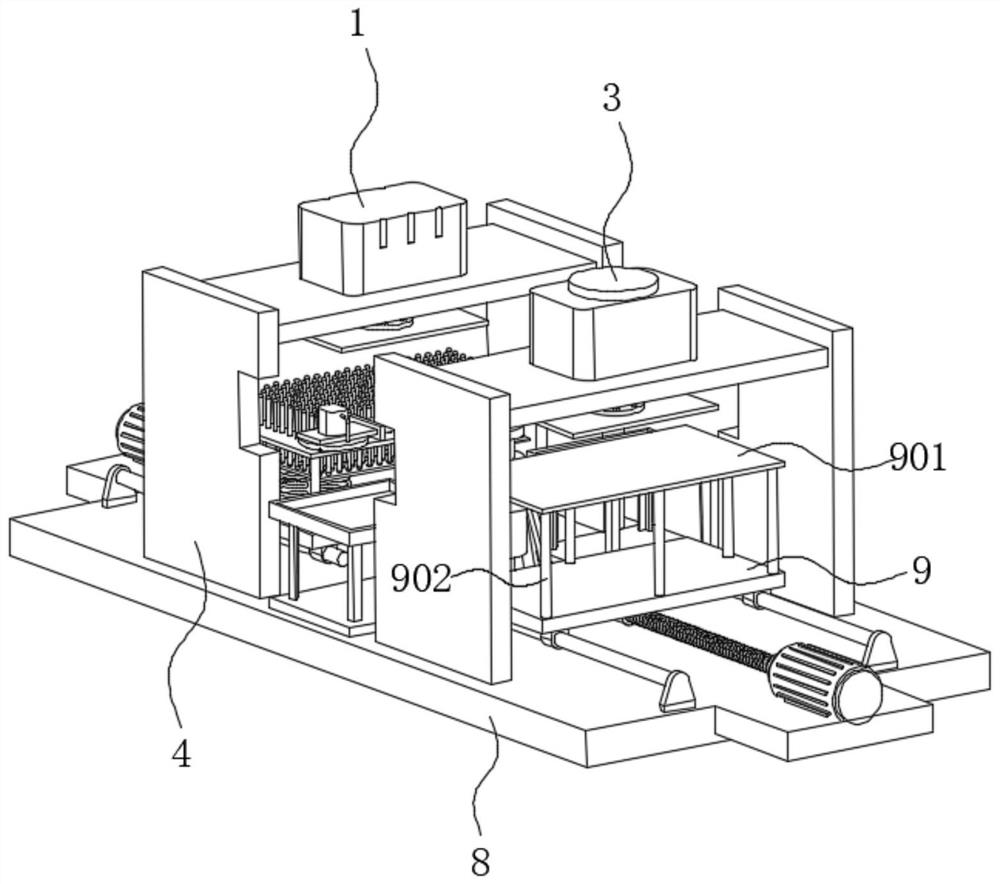

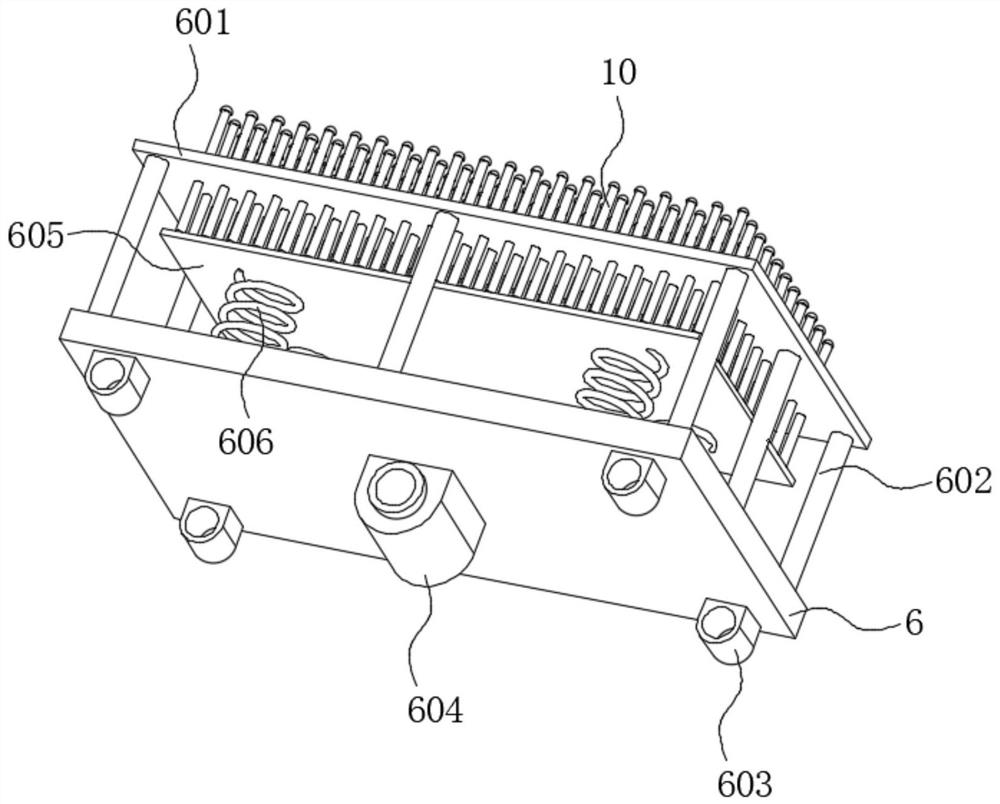

[0036] see Figure 1-6 As shown, the present invention is a hot stamping machine with pattern concave-convex printing and hot stamping integrally formed, comprising a base 8, the upper end of the base 8 is fixed with a first protective frame 5, and the upper end of the base 8 behind the first protective frame 5 is fixed with a second protective frame. Frame 4, the first cylinder 1 is fixed on the upper end of the first protective frame 5, and the top position inside the first protective frame 5 is provided with a printing convex plate 7, and the printing convex plate 7 is fixedly connected with the piston end of the first cylinder 1, and the connecting plate There is an active hole 6011 on the surface of 601, and a rubber rod 10 is arranged inside the active hole 6011. Place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com