Efficient coloring device for energy-saving building material hollowed-out plate manufacturing

A high-efficiency, building material engraving technology, applied in spraying devices, spray booths, etc., can solve the problems of endangering the health of environmental sanitation workers, time-consuming and laborious, and producing harmful gases, so as to ensure the coloring effect, expand the scope of application, and ensure the environment. Hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

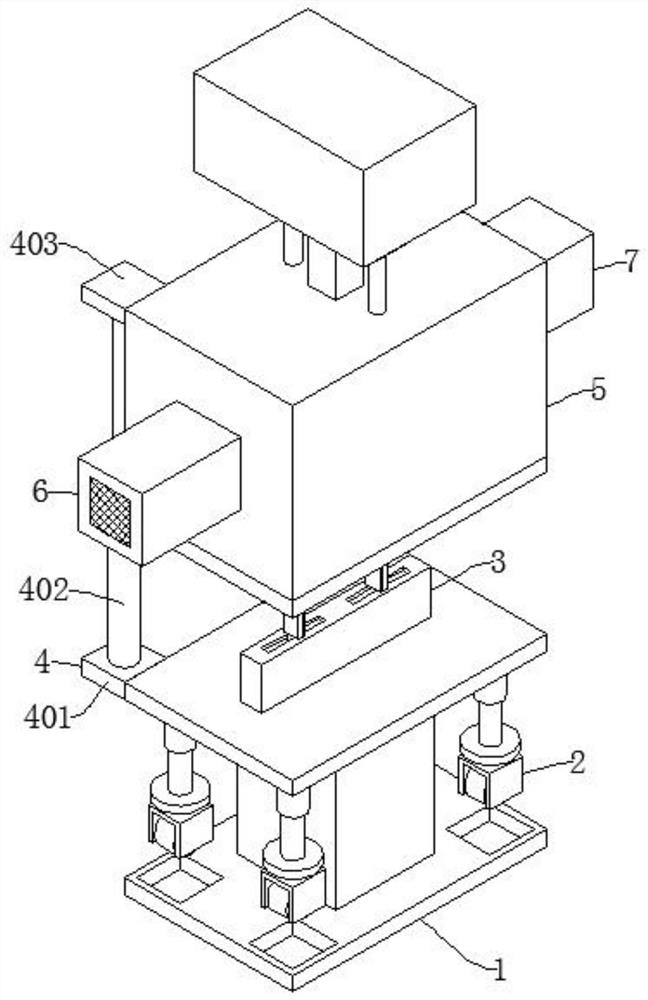

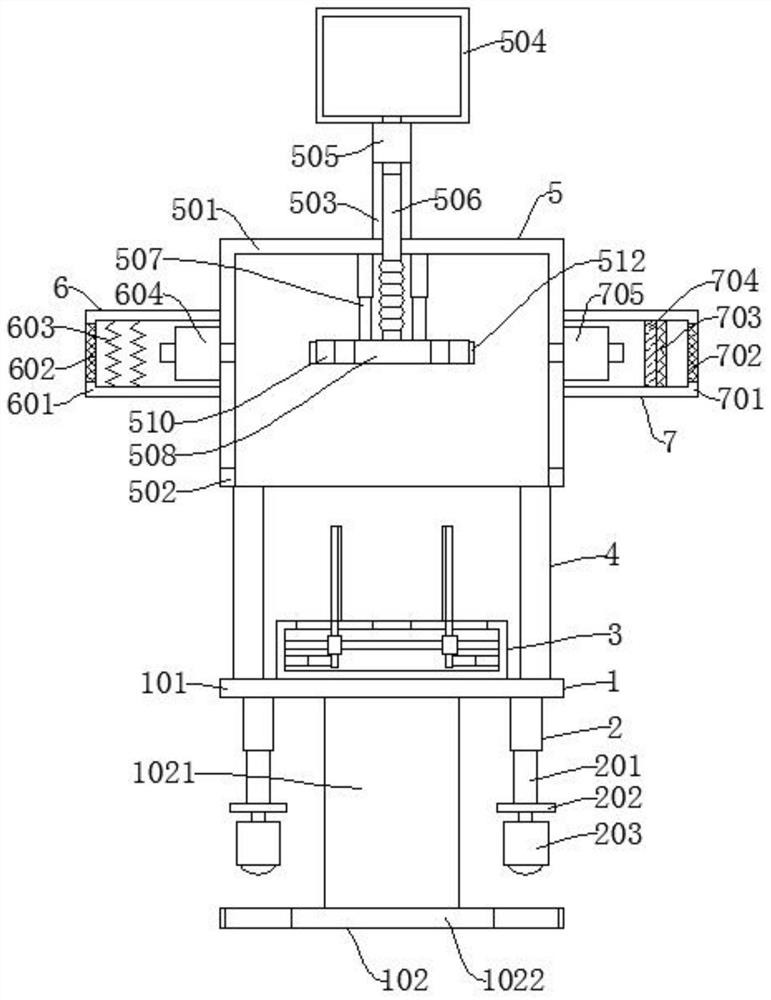

[0040] Such as figure 1 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a high-efficiency coloring device for the manufacture of energy-saving building material hollow boards, including a supporting mechanism 1 for supporting equipment, a moving mechanism 2, a clamping mechanism 3, and a lifting mechanism 4, and a moving mechanism 2 is installed on the supporting mechanism 1 to support A clamping mechanism 3 is installed above the mechanism 1, and a lifting mechanism 4 is fixed on the rear of the supporting mechanism 1, which also includes a coloring mechanism 5, a drying mechanism 6, and a purification mechanism 7. The coloring mechanism 5 is arranged above the clamping mechanism 3, and the drying mechanism 6 is installed on one side of the coloring mechanism 5, and the purification mechanism 7 is installed on the other side of the coloring mechanism 5;

[0041] The coloring mechanism 5 includes a closed box 501, a gasket 502, a fixed rod 503, a paint...

Embodiment 2

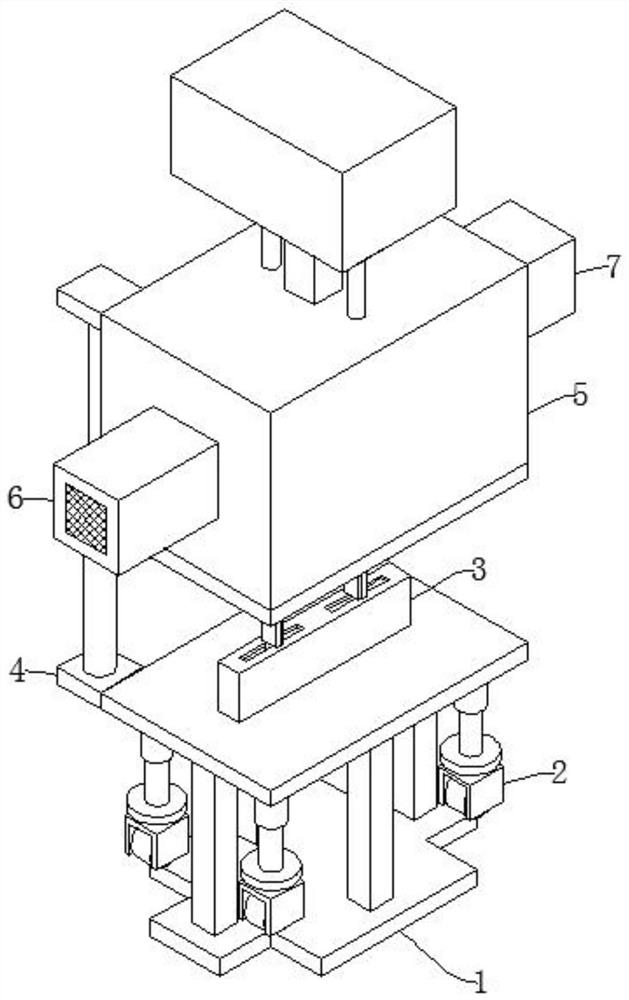

[0047] Such as figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the support table 1021 and the support plate 1022 are replaced by support rods 1023 and cross plates 1024. During the operation of the device, the support rods 1023 and cross plates 1024 work together to align The board 101 is supported and fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com