Fabric with warp knitting yarn diameter structure and manufacturing method thereof

A wire diameter and fabric technology is applied in the field of fabrics with warp knitting wire diameter structure and its production, which can solve the problems of lack of change, poor three-dimensional feeling, single mesh structure, etc. Stability and support, the effect of showing a sense of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

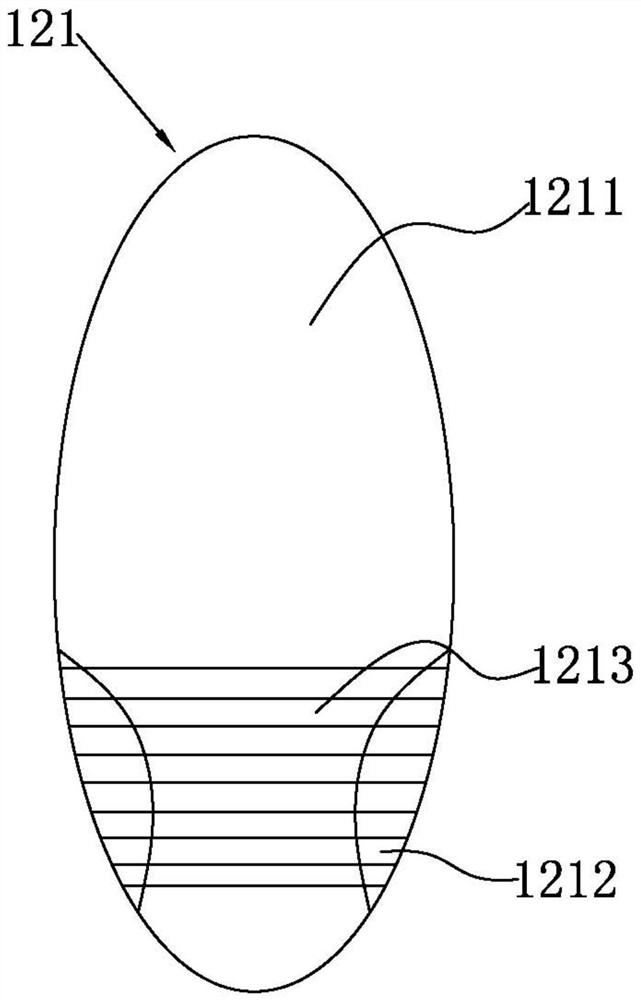

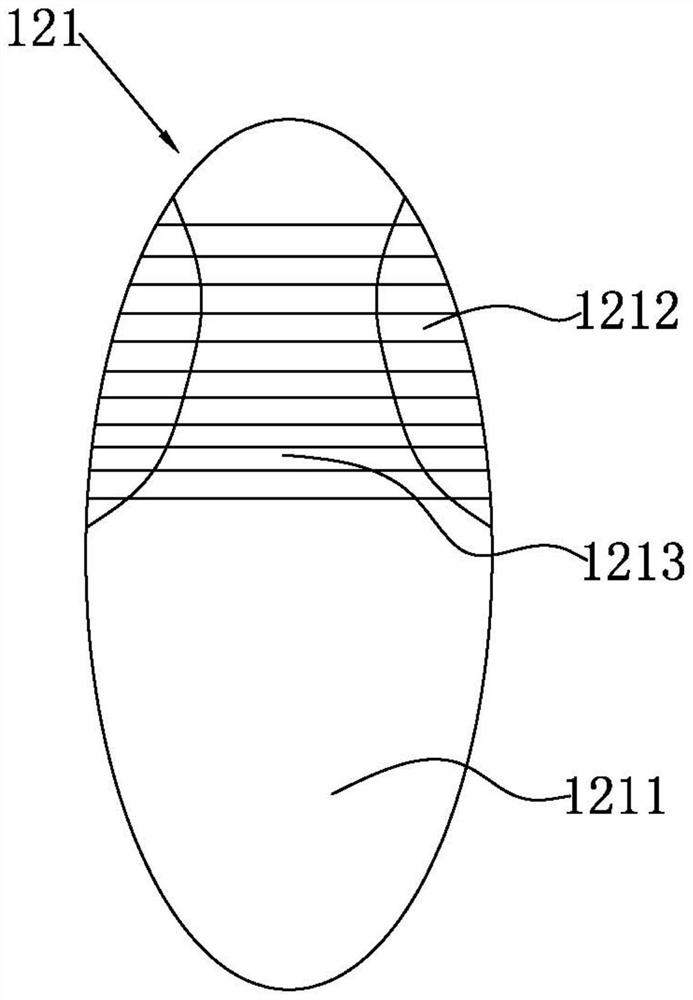

[0055] refer to figure 1 , 7 ,8, figure 1 It is a structural schematic diagram of a fabric having a warp-knitted wire diameter structure in the present invention; Figure 7 It is a cross-sectional view of the fabric with warp-knitted wire diameter structure of the present invention; Figure 8 It is the physical figure of the fabric with the warp-knitted wire diameter structure of the present invention.

[0056] This embodiment provides a fabric with a warp-knitted wire diameter structure, comprising a fabric body integrally woven by a double-needle bed high-speed warp-knitting machine, the fabric body comprising a surface layer 1 and a bottom layer woven under the surface layer 1 2 and an intermediate layer 3 woven between the surface layer 1 and the bottom layer 2.

[0057] The surface layer 1 includes a plurality of first yarns, and the plurality of first yarns are cross-woven to form the surface layer 1 . The surface layer 1 includes a plain weave area 11 and a mesh ar...

Embodiment 2

[0063] refer to figure 1 , 7 ,8, figure 1 It is a structural schematic diagram of a fabric having a warp-knitted wire diameter structure in the present invention; Figure 7 It is a cross-sectional view of the fabric with warp-knitted wire diameter structure of the present invention; Figure 8 It is the physical figure of the fabric with the warp-knitted wire diameter structure of the present invention.

[0064] This embodiment provides a fabric with a warp-knitted wire diameter structure, comprising a fabric body integrally woven by a double-needle bed high-speed warp-knitting machine, the fabric body comprising a surface layer 1 and a bottom layer woven under the surface layer 1 2 and an intermediate layer 3 woven between the surface layer 1 and the bottom layer 2.

[0065] The surface layer 1 includes a plurality of first yarns, and the plurality of first yarns are cross-woven to form the surface layer 1 . The surface layer 1 includes a plain weave area 11 and a mesh ar...

Embodiment 3

[0072] refer to figure 1 , 7 ,8, figure 1 It is a structural schematic diagram of a fabric having a warp-knitted wire diameter structure in the present invention; Figure 7 It is a cross-sectional view of the fabric with warp-knitted wire diameter structure of the present invention; Figure 8 It is the physical figure of the fabric with the warp-knitted wire diameter structure of the present invention.

[0073] This embodiment provides a fabric with a warp-knitted wire diameter structure, comprising a fabric body integrally woven by a double-needle bed high-speed warp-knitting machine, the fabric body comprising a surface layer 1 and a bottom layer woven under the surface layer 1 2 and an intermediate layer 3 woven between the surface layer 1 and the bottom layer 2.

[0074] The surface layer 1 includes a plurality of first yarns, and the plurality of first yarns are cross-woven to form the surface layer 1 . The surface layer 1 includes a plain weave area 11 and a mesh ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com