Moisture-proof floating cable

A technology of floating cable and moisture-proof layer, applied in the direction of floating cable, insulated cable, cable, etc., can solve the problems of simple moisture-proof structure, poor moisture-proof effect, difficult cable, etc., and achieve the effect of strengthening water-blocking and moisture-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

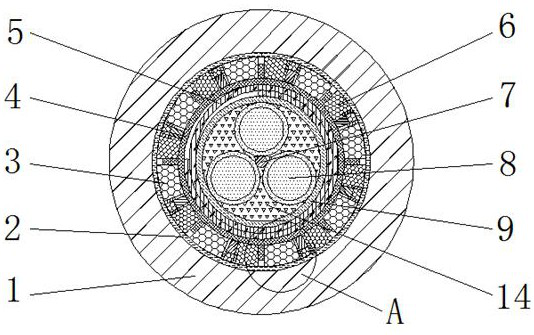

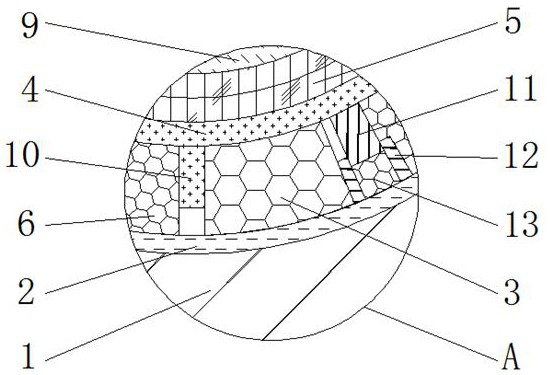

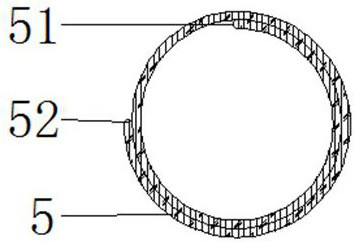

[0029] Such as figure 1 A moisture-proof floating cable shown includes a cable core, a moisture-proof protective layer and an outer sheath 1 arranged in sequence from the inside to the outside, and at least two cable cores 8 are arranged in the cable core (the figure shows three cable core 8); the outside of the cable core is provided with an isolation layer 9, the isolation layer 9 is a shielding layer, and the moisture-proof protective layer includes an inner moisture-proof layer 5, a rotating sleeve 4 and an outer Vapor barrier 2, such as image 3 As shown, the inner moisture-proof layer 5 is coiled and wrapped on the outside of the isolation layer 9, and the inner end side 51 of the inner moisture-proof layer 5 is fixedly connected to the isolation layer 9, and the rotating sleeve 4 is set inside The outer side of the moisture-proof layer 5, and the outer end side 52 of the inner moisture-proof layer 5 is fixedly connected on the rotating sleeve 4; as Figure 4 As shown,...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

[0037] In this embodiment, the isolation layer 9 is a water blocking tape wrapping layer.

[0038] In this embodiment, the central angle corresponding to the part forming the double-layer structure on the inner moisture-proof layer 5 is 180°.

[0039] In this example, if figure 1 As shown, the center of the cable core is provided with a reinforcing rope 7 extending along the length direction of the cable, and the reinforcing rope 7 is a Kevlar fiber rope. The Kevlar fiber rope can greatly improve the tensile performance of the cable body, thereby improving the load-bearing capacity of the floating cable.

[0040] In this example, if figure 1 As shown, a filler 14 is provided between the isolation layer 9 and each cable core 8, and the filler 14 is hollow short fiber. The hollow short fiber can realize the filling function of the filler 14, and the hollow short fiber is hollow inside, which can reduce the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com