Non-woven fabric horizontal conveying and pressing equipment

A non-woven, horizontal technology, applied in textiles and papermaking, textile material processing, textile processing machine accessories, etc., can solve problems such as difficult to eliminate, non-woven folds, material waste, etc. Wrinkle-removing effect, flatness-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

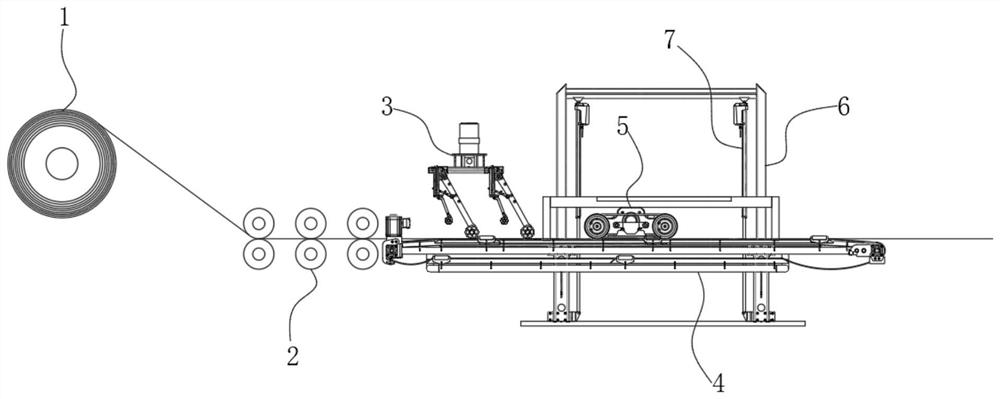

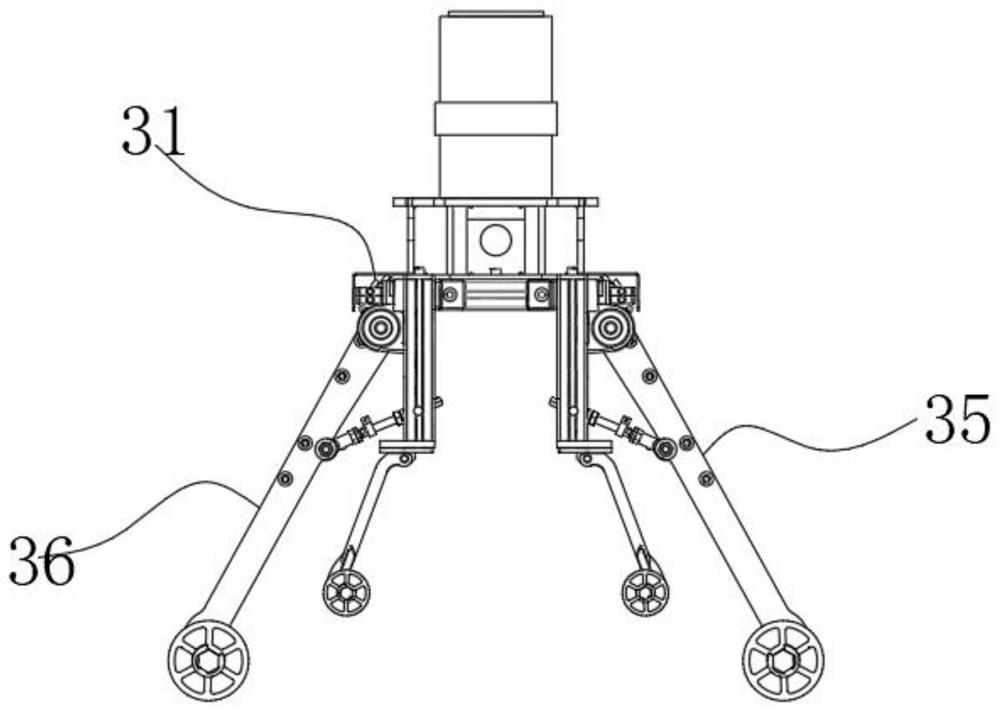

[0043] see Figure 1~6 , the present invention provides a kind of non-woven fabric horizontal transmission and pressing equipment, comprising a discharge roller 1, the discharge roller 1 is used to continuously supply non-woven fabrics at intervals, and the non-woven fabrics pass through the conveying roller group 2 and Horizontal transmission component 4;

[0044] The horizontal conveying assembly 4 is provided with a pressing assembly 3 and a floating leveling assembly 5 sequentially along the moving direction of the non-woven fabric, so that the non-woven fabric can be pressed and wrinkled by the pressing assembly 3 during the conveying process, and then Then the floating leveling component 5 is used for leveling, which is beneficial to improve the overall leveling;

[0045] Wherein, the floating leveling assembly 5 is fixed on the top of the horizontal transmission assembly 4, and the horizontal transmission assembly 4 is vertically slidably arranged on the adjustment bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com