Low-temperature demulsifier for thick oil and preparation method of low-temperature demulsifier

A demulsifier and low-temperature technology, applied in the field of low-temperature demulsifier and its preparation, can solve the problems of increased production cost and heating energy consumption, and achieve the effects of low concentration, strong adaptability and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

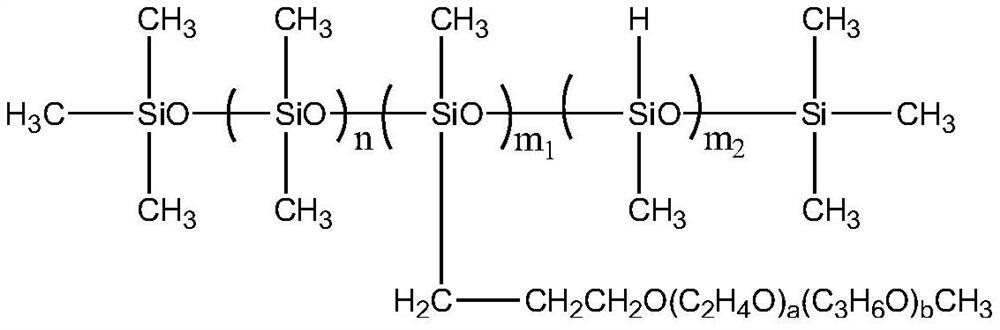

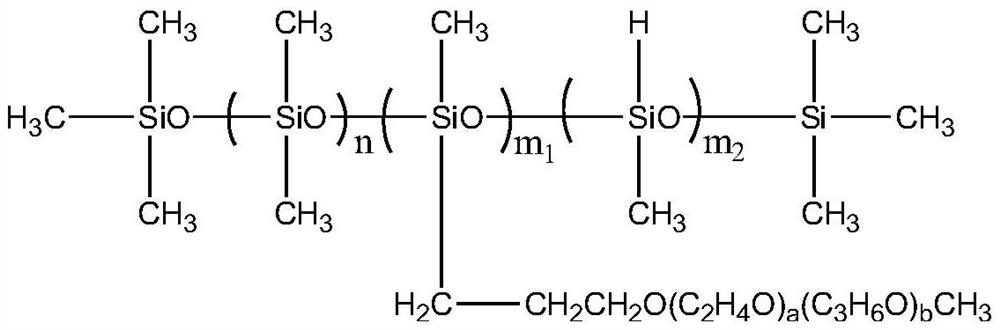

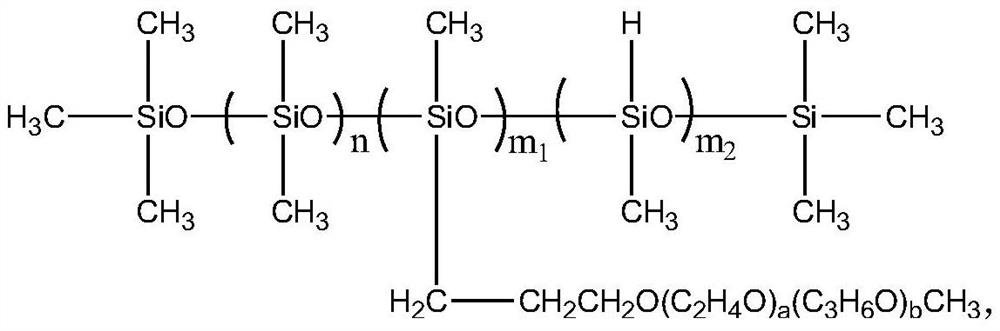

Method used

Image

Examples

Embodiment 1

[0030] (1) In the three-necked flask with a swiveling thermometer, a stirrer and a reflux condenser, add 1 mol of hydrogen-containing silicone oil, 0.1 mol of methyl-terminated allyl polyoxyethylene polyoxypropylene ether and 2 mol of solvent isopropanol in sequence, and feed Nitrogen protection, then slowly increase the temperature to 80°C, after the temperature rises stably, add the catalyst chloroplatinic acid dropwise, after constant temperature for 1h, the reaction ends, and the mixture is obtained;

[0031] (2) Distill the above mixture under reduced pressure to remove the solvent isopropanol, then wash it with ethanol for 3 times, then put it in an oven at 80°C to remove the residual ethanol and solvent isopropanol, and obtain low-temperature demulsifier A 1 .

[0032] The hydrogen-containing silicone oil is a hydrogen-containing silicone oil with a Si-H mass fraction of 0.3-1%.

[0033] The dropping rate of the catalyst chloroplatinic acid is 10 drops / min, and the dos...

Embodiment 2

[0043] (1) In the three-necked flask of the swiveling thermometer, the stirrer and the reflux condenser, add 1mol of hydrogen-containing silicone oil, 0.3mol of methyl-terminated allyl polyoxyethylene polyoxypropylene ether and 3mol of solvent cyclohexanone in turn, and feed Nitrogen protection, then slowly raise the temperature to 85°C, after the temperature rise is stable, the catalyst chloroplatinic acid is added dropwise, and the reaction ends after constant temperature for 2 hours, and the mixture is obtained;

[0044] (2) Distill the above mixture under reduced pressure to remove the solvent cyclohexanone, then wash it with ethanol for 3 times, then put it in an oven at 80°C to remove the residual ethanol and solvent cyclohexanone, and obtain low-temperature demulsifier A 2 .

[0045] The hydrogen-containing silicone oil is a hydrogen-containing silicone oil with a Si-H mass fraction of 0.3-1%.

[0046] The catalyst is chloroplatinic acid, the dropping rate is 15 drops / ...

Embodiment 3

[0056] (1) In the three-necked flask with a wandering thermometer, a stirrer and a reflux condenser, add 1 mol of hydrogen-containing silicone oil, 0.5 mol of methyl-terminated allyl polyoxyethylene polyoxypropylene ether and 4 mol of solvent isopropanol in sequence, and feed Nitrogen protection, then slowly raise the temperature to 90°C, after the temperature rise is stable, the catalyst chloroplatinic acid is added dropwise, the reaction ends after constant temperature for 3 hours, and the mixture is obtained;

[0057] (2) Distill the above mixture under reduced pressure to remove the solvent isopropanol, then wash it with ethanol for 4 times, and then put it in an oven at 80°C to remove the residual ethanol and solvent isopropanol to obtain low-temperature demulsifier A 3 .

[0058] The hydrogen-containing silicone oil is a hydrogen-containing silicone oil with a Si-H mass fraction of 0.3-1%.

[0059] The catalyst is chloroplatinic acid, the dropping rate is 12 drops / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com