Oligogalacturonic acid polysaccharide, compound and its preparation method and application

A technology of galactooligosaccharides and uronic acid polysaccharides, which is applied in the field of polysaccharides, can solve the problems of no galacturonic acid polysaccharides, etc., and achieve the effects of improving anti-tumor immunity, reducing hematological toxicity, and increasing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

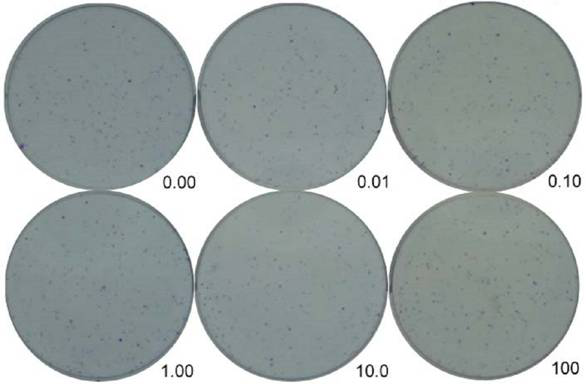

Image

Examples

Embodiment 1

[0080] Preparation of galacturonan polysaccharides:

[0081] (1) Rinse the orange peel, boil it for decolorization, and degrease with petroleum ether twice to provide by-products such as citrus essential oil and naringin; ultrasonic crushing can efficiently destroy the cell wall structure of the peel and promote the release of crude pectin polysaccharides in the subsequent steps;

[0082] (2) Acidification pretreatment: dissolve the broken peel with dilute hydrochloric acid or sulfurous acid, control the pH value at 5.0-6.0, 30min, form a stable water-soluble pectin gel, and filter to remove the residue;

[0083] (3) Enzymolysis: Add 6 mg / g cellulase, maintain the temperature at 38°C, and enzymolysis time 70 minutes;

[0084] (4) Alkaline hydrolysis-microwave method: In a closed culture tank, add an equivalent amount of 4mol / L NaOH to the crude pectin gel aqueous solution, control the pH at 12.0-13.0, and heat it to 80-100°C with microwaves. Microwave energy can cause water M...

Embodiment 2

[0094] Preparation of galacturonan polysaccharides:

[0095] (1) Rinse the apple peel;

[0096] (2) Alkaline hydrolysis: Dissolve 400g of peel in 2L of water, add 3mol / L NaOH 400ml, stir for 30 min, and cool to room temperature;

[0097] (3) Enzymolysis: add 5 mg / g cellulase, maintain the temperature at 38°C, and enzymolysis time 90 minutes;

[0098] (4) The HG crude content is less than 70%, no pre-deproteinization step is required, and Saccharomyces cerevisiae ( Saccharomyces cerevisiae ) fermentation method to prolong the fermentation and degradation time: Add 2% sucrose solution to active dry yeast of brewer’s brewing yeast, stir evenly, and place it at 25-30°C for 2-4 hours to activate it; in 2-5% pectin aqueous solution, add 1-5% activated yeast, 30°C, ferment for 24-48 hours;

[0099] (5) Use ultrafiltration membrane for fine extraction, the pore size of the ultrafiltration membrane is 1-10nm, maintain a low pressure difference of 0.05-0.5MPa for continuous high-flo...

Embodiment 3

[0103] The galacturonic acid polysaccharide prepared in Example 1 was used.

[0104] Prepare 625 parts by weight of galacturonic acid polysaccharide, 25 parts by weight of astragalus, 10 parts by weight of fried hawthorn, 10 parts by weight of red dates and 8 parts by weight of tangerine peel.

[0105] Wash astragalus, fried hawthorn, red dates and tangerine peel, ultrasonically crush, sieve, soak in 10 times double distilled water for 30 minutes, fry on low heat for 1 hour, and filter to make an extract; then mix the extract with galacto-oligosaccharide Aldehydic polysaccharides are fully mixed to make a powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com