Method for preparing aminoacetaldehyde dialkyl acetal

A technology of aminoacetaldehyde dialkyl alcohols and low-carbon alcohols, which is applied in chemical instruments and methods, the preparation of organic compounds, and the preparation of aminohydroxyl compounds, etc., and can solve the problems of unfavorable industrial production, large amount of "three wastes" and large consumption Energy consumption and other issues, to achieve significant application value, simplified operation, less dangerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

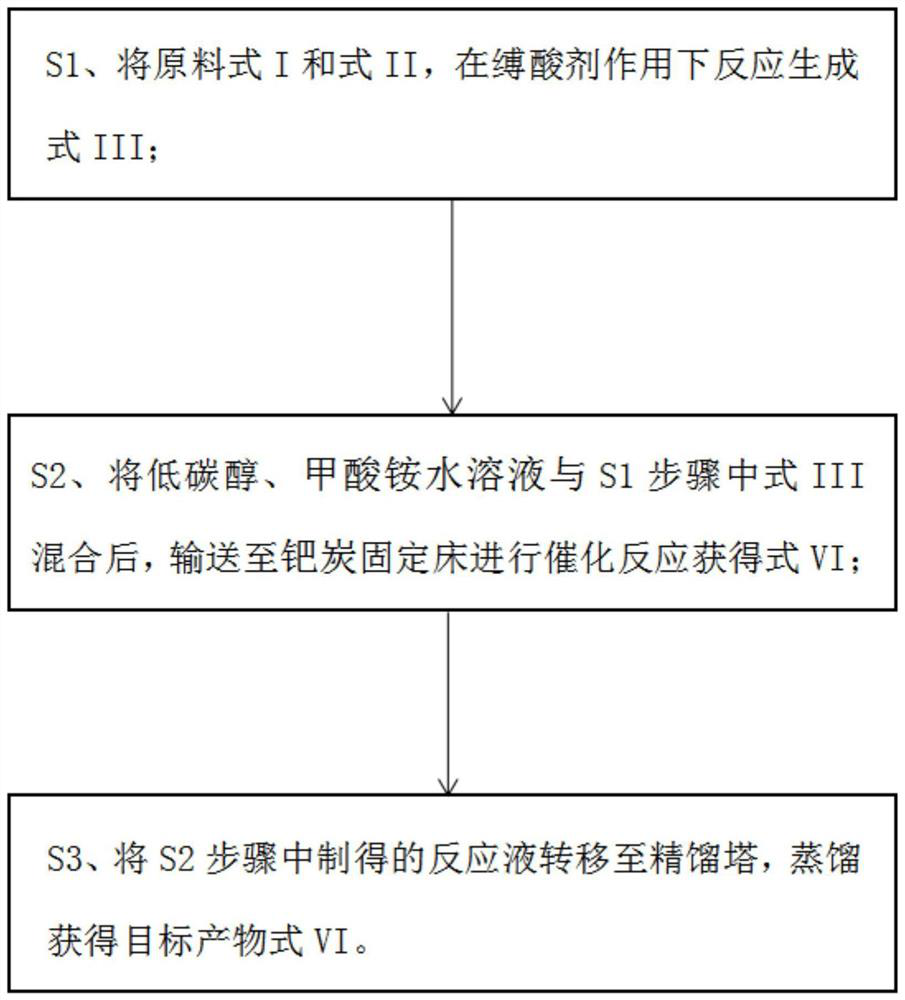

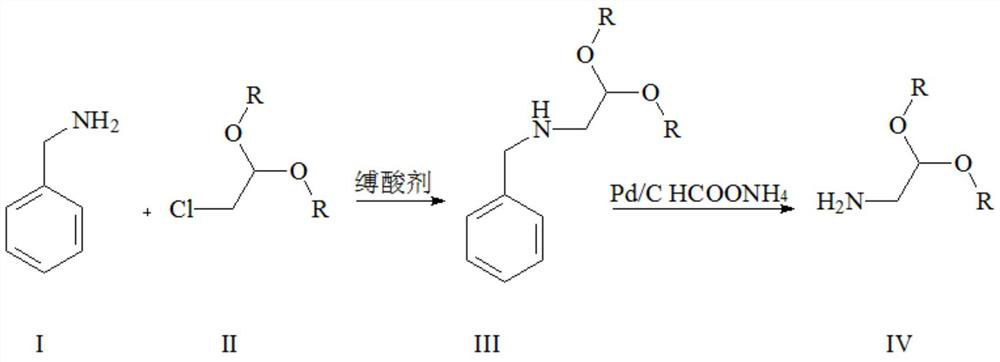

Method used

Image

Examples

Embodiment 1

[0045] The method for preparing aminoacetaldehyde dimethyl acetal in this embodiment comprises the following steps:

[0046] 1) Preparation of formula III: Add benzylamine formula I (428g, 4mol) into the reaction flask, then add acid-binding agent potassium carbonate (276g, 2mol), heat up to 120-125°C, and control the temperature at 120-125°C, Start to slowly add formula II (R is methyl, 248g, 2mol) dropwise. After the dropwise addition, keep warm for 1-2 hours, cool down and suction filter, and the filtrate is distilled under reduced pressure to reclaim benzylamine to obtain the raffinate formula III (385g). Go to the next reaction.

[0047] 2) Preparation of aminoacetaldehyde dimethyl acetal: Add 1000ML of methanol, 50g of water, and ammonium formate (126g, 2mol) to the raffinate formula III obtained in the above steps, raise the temperature to 60-65°C, and raise the temperature of the palladium carbon fixed bed to 60-65°C, start the damping pump, adjust the flow rate to 20...

Embodiment 2

[0049] The method for preparing aminoacetaldehyde dimethyl acetal in this embodiment comprises the following steps:

[0050] 1) Preparation of formula III: add benzylamine formula I (856g, 8mol) into the reaction flask, then add acid-binding agent potassium carbonate (414g, 3mol), heat up to 120-140°C, and control the temperature at 120-140°C, Start to slowly add formula II (R is methyl, 248g, 2mol) dropwise. After the dropwise addition, keep warm for 1-2 hours, cool down and suction filter, and the filtrate is distilled under reduced pressure to reclaim benzylamine to obtain the raffinate formula III (385g). Go to the next reaction.

[0051]2) Preparation of aminoacetaldehyde dimethyl acetal: Add 1000ML of ethanol, 50g of water, and ammonium formate (252g, 4mol) to the raffinate formula III obtained in the above steps, raise the temperature to 60-80°C, and raise the temperature of the palladium carbon fixed bed to At 60-80°C, start the damping pump, adjust the flow rate to 2...

Embodiment 3

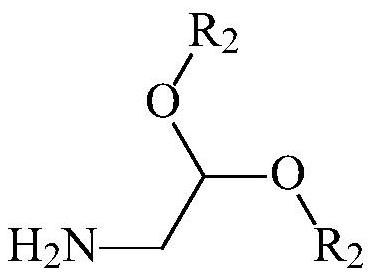

[0054] This embodiment prepares the method for aminoacetaldehyde diethyl acetal, comprises the following steps:

[0055] 1) Preparation of formula III: Add benzylamine formula I (428g, 4mol) into the reaction flask, then add acid-binding agent potassium carbonate (276g, 2mol), heat up to 120-125°C, and control the temperature at 120-125°C, Start to slowly drop formula II (R is ethyl, 266g, 2mol), after the dropwise addition is completed, keep warm for 1-2 hours, cool down and suction filter, and the filtrate is distilled under reduced pressure to reclaim benzylamine to obtain the raffinate formula III (440g), directly Go to the next reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com