Melting and cooling device for metal casting

A cooling device and metal casting technology, applied in the field of metal casting melting and cooling devices, can solve the problems affecting the quality of metal castings and cannot be cooled, and achieve the effects of ensuring production and processing quality, uniform and effective cooling and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

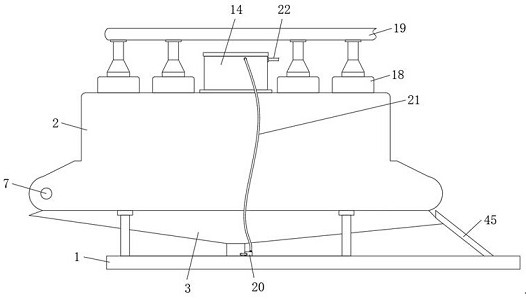

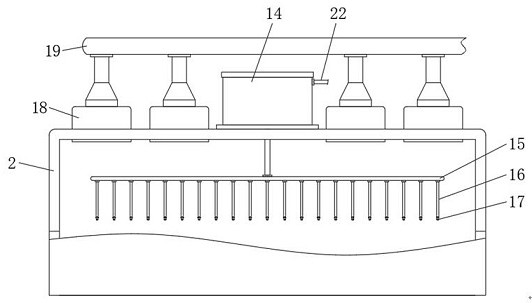

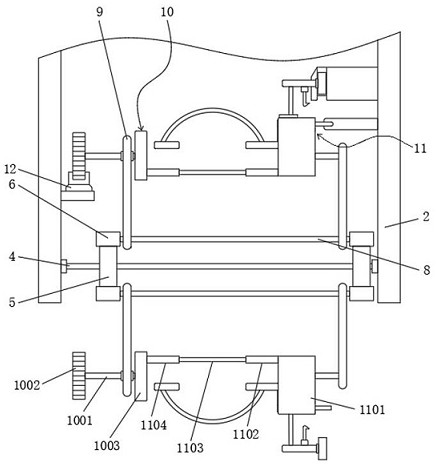

[0030] Embodiment one, by Figure 1 to Figure 6Given, the present invention includes a base 1, a cooling box 2 is installed on the top of the base 1, and a cooling water collection cover 3 is installed on the top of the cooling box 2. By setting the cooling water collection cover 3, water can be effectively collected and cooled. Rotating shaft 4 is mounted on the lower part of the inner side of box 2 to rotate equidistantly, first gear 5 is fixedly installed on both sides of rotating shaft 4, and transmission chain 6 is installed between the surfaces of first gear 5 on the same side of rotating shaft 4 A motor 7 is installed on one side of the surface of the cooling box 2, and the output end of the motor 7 is fixedly connected with one end of one of the rotating shafts 4, and through the setting of the rotating shaft 4, the first gear 5, the transmission chain 6 and the motor 7, it can effectively The two transmission chains 6 are equidistantly fixed with a fixed rod 8, and bo...

Embodiment 2

[0033] Embodiment two, on the basis of embodiment one, by Figure 5 Given, the middle part of the second disk 1101 side is provided with a sliding groove 13, the inside of the sliding groove 13 is equipped with an L-shaped pressing plate 23, the inner side of the L-shaped pressing plate 23 is fixedly installed with an arc bar 24, and one end of the arc bar 24 A square pressing plate 25 is fixedly installed, so as to clamp the placed metal casting.

Embodiment 3

[0034] Embodiment three, on the basis of embodiment two, by Figure 5 Provided, the inner side of the sliding groove 13 is provided with a sliding card slot 26, and the inside of the sliding card slot 26 is slidably equipped with a T-shaped slider 27, and one end of the L-shaped pressing plate 23 is fixedly connected with the T-shaped slider 27, and the T-shaped slider 27 A first spring 28 and a first corrugated protection ring 29 are installed between the bottom of the sliding card slot 26, and the first corrugated protection ring 29 is sleeved on the surface of the first spring 28, so that the L-shaped pressing plate 23 can be driven to move Reset adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com