Crushing device applied to logistics

A crushing device and logistics technology, applied in grain processing, presses, manufacturing tools, etc., can solve the problems of affecting work efficiency, short action time of packaging and crushing workpieces, insufficient crushing, etc., and achieve the effect of ensuring crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

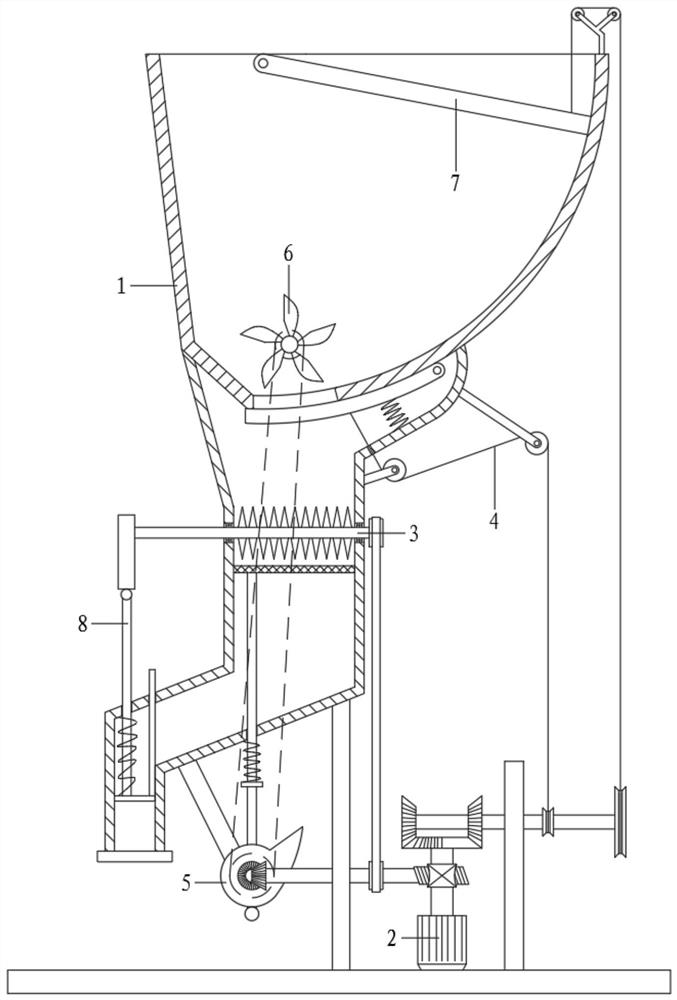

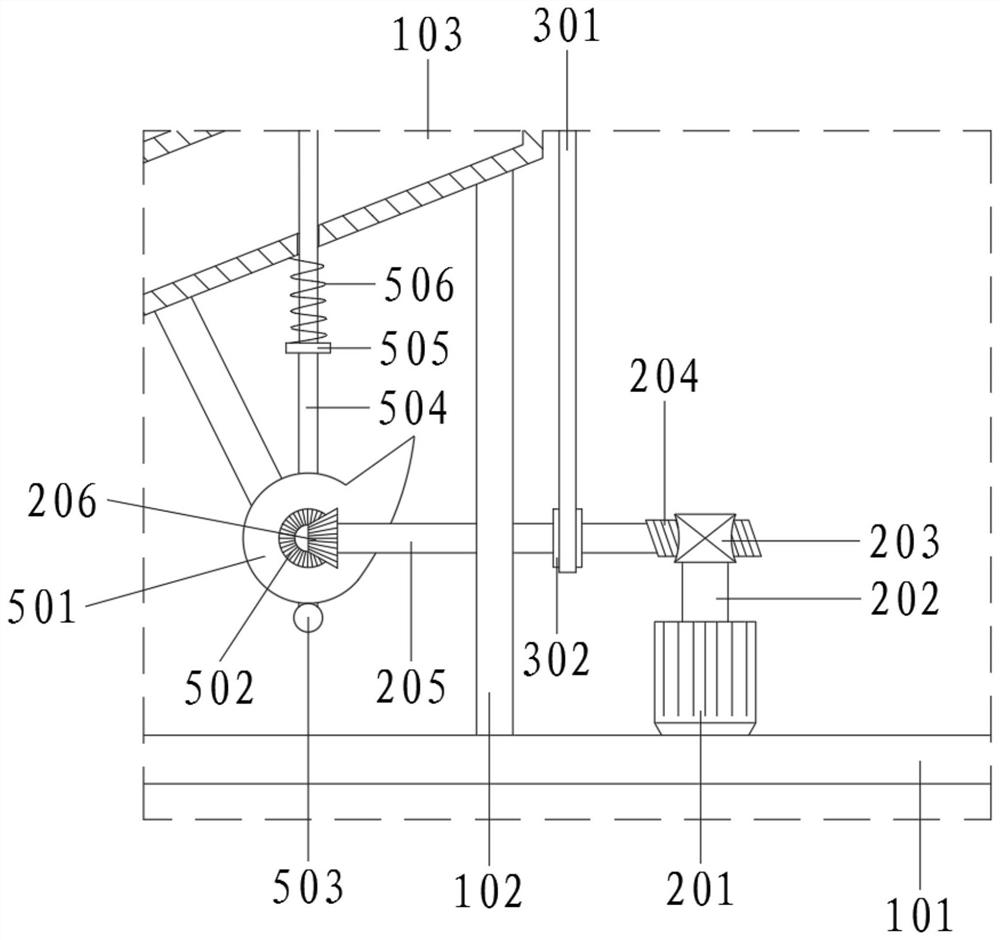

[0059] With reference to the accompanying drawings, a crushing device for logistics includes a tank assembly 1, a drive assembly 2, a first-class crushing assembly 3, a compression assembly 8 and a lifting assembly 5;

[0060] The tank assembly 1 includes a base 101, a bracket 102, a crushing cylinder 103, a feeding pipe 104, and a hopper 105. The crushing cylinder 103 is connected above the base 101 through the bracket 102. The top of the crushing cylinder 103 is connected to a hopper 105, and the bottom is bent and connected to a Vertical feeding pipe 104; the bottom of the hopper 105 is provided with a discharge port 106, and the bottom end of the feeding pipe 104 is detachably equipped with a bottom cover 107;

[0061] The base 101 is provided with a driving assembly 2, the pulverizing cylinder 103 is provided with a type of crushing assembly 3, and the feeding pipe 104 is provided with a compression assembly 8; A lifting component 5 is arranged below the crushing componen...

Embodiment 2

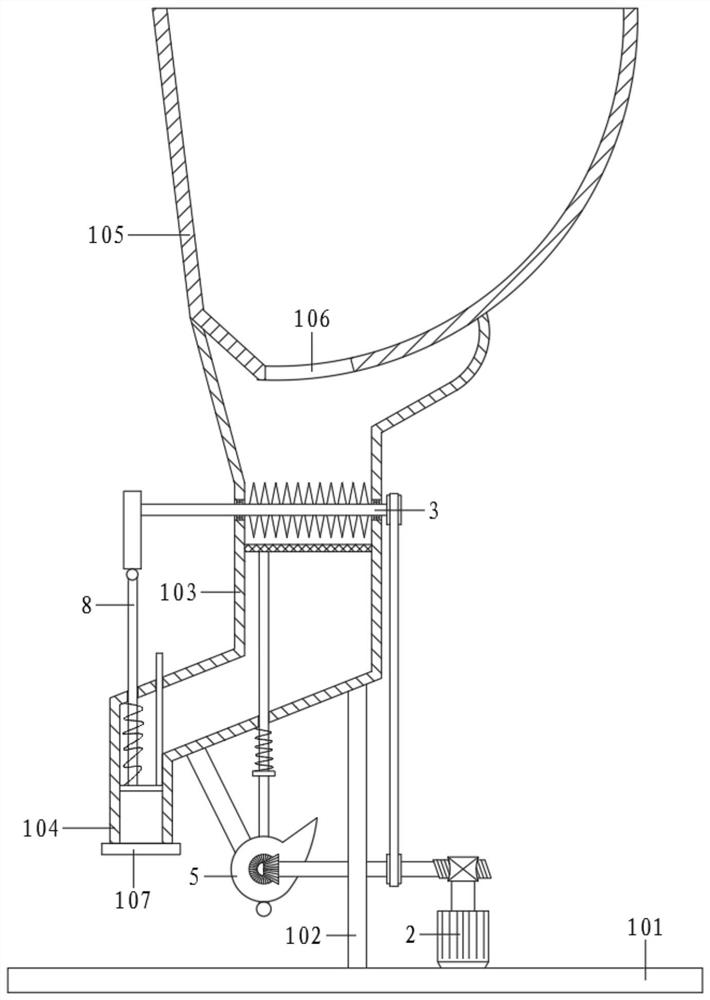

[0063] With reference to the accompanying drawings, a crushing device for logistics includes a tank assembly 1, a drive assembly 2, a first-class crushing assembly 3, a compression assembly 8 and a lifting assembly 5;

[0064] The tank assembly 1 includes a base 101, a bracket 102, a crushing cylinder 103, a feeding pipe 104, and a hopper 105. The crushing cylinder 103 is connected above the base 101 through the bracket 102. The top of the crushing cylinder 103 is connected to a hopper 105, and the bottom is bent and connected to a Vertical feeding pipe 104; the bottom of the hopper 105 is provided with a discharge opening 106, and the bottom end of the feeding pipe 104 is detachably screwed with a bottom cover 107;

[0065] The base 101 is provided with a driving assembly 2, the pulverizing cylinder 103 is provided with a type of crushing assembly 3, and the feeding pipe 104 is provided with a compression assembly 8; A lifting component 5 is arranged below the crushing compon...

Embodiment 3

[0083] On the basis of the above examples,

[0084] Also includes a discharge assembly 4, the discharge assembly 4 includes an incomplete bevel gear 401, a driven bevel gear 402, a fourth shaft 403, a support 404, a first winding wheel 405, a first stay rope 406, and a type of lead wheel Group 407, baffle plate 408 and stage clip 409;

[0085] The baffle plate 408 is arranged below the discharge port 106, and the right end is hinged to the outer wall of the hopper 105; a compression spring 409 is also connected between the baffle plate 408 and the inner wall of the crushing cylinder 103; an incomplete bevel gear 401 is connected to the top of the No. 1 shaft 202; The part is connected with a bearing 404, and the No. 4 shaft 403 runs horizontally and rotates to connect the bearing 404; the left section of the No. 4 shaft 403 is symmetrically fixed with a driven bevel gear 402, and the driven bevel gear 402 meshes with the incomplete bevel gear 401; No. 1 reel 405 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com