Filter backwashing system and process, control method

A filter and process technology, which is applied in the filter backwashing system and process and control field, can solve the problems of economic loss, cleanness, organic matter and microorganisms, etc., so as to improve the backwashing effect, reduce the number of backwashing, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

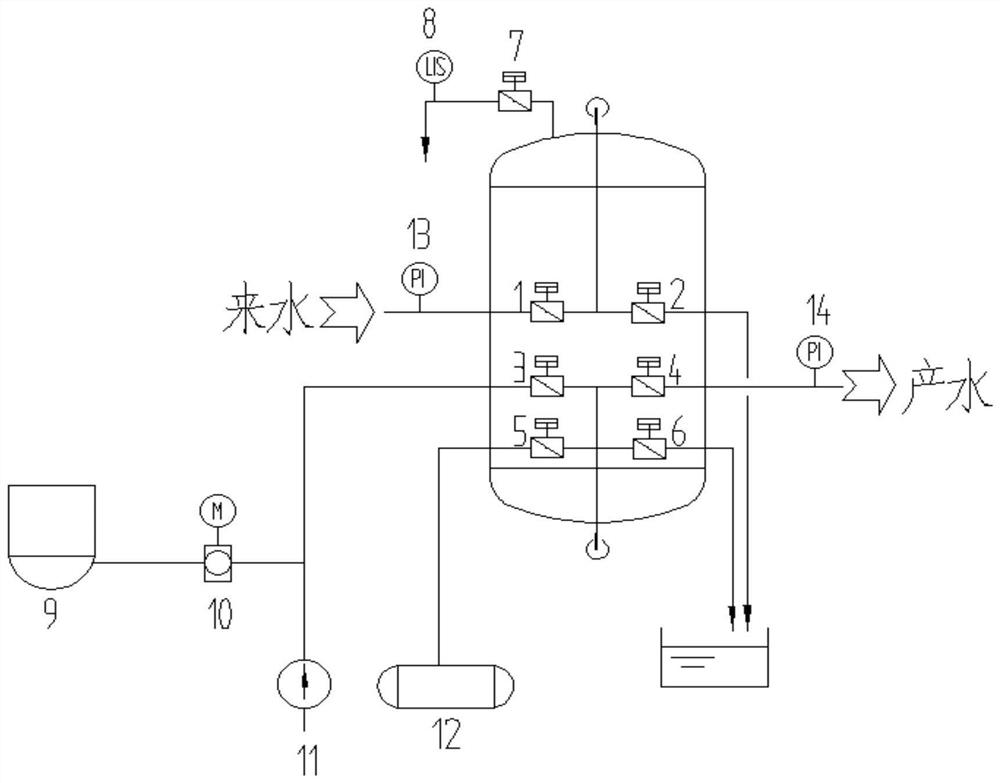

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

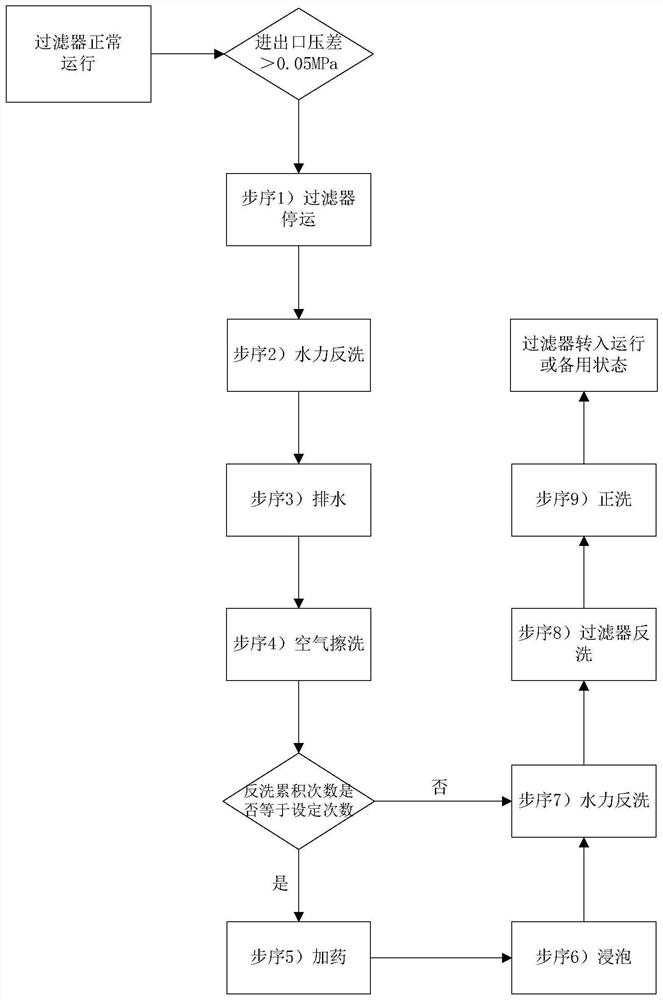

[0034] refer to figure 1 , the filter backwash process of the present invention comprises the following steps:

[0035] Step 1) Filter outage: When the filter reaches the backwashing condition (that is, the pressure difference between the inlet and outlet of the filter reaches 0.05MPa), close the filter inlet valve 1 and outlet valve 4, and turn to the next filter after the filter is out of service. step sequence.

[0036] Step 2) Hydraulic backwashing: open the filter backwashing water inlet valve 3 and backwashing drain valve 2, start the filter backwashing water pump 11, backwashing time is 5 minutes, and the backwashing water is directly discharged to the recovery pool. After the sequence time reaches the set time, it will transfer to the next sequence.

[0037] Step 3) Drainage: Stop filter backwash pump 11, close filter backwash inlet valve 3 and bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com