Continuous processing method of egg roll

A processing method and continuous technology, which are applied in the direction of dough processing, baking pancakes, baking tins, etc., can solve the problems of discontinuity, low processing efficiency of egg rolls, and inability to guarantee the quality of egg rolls, etc. Achieve the effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

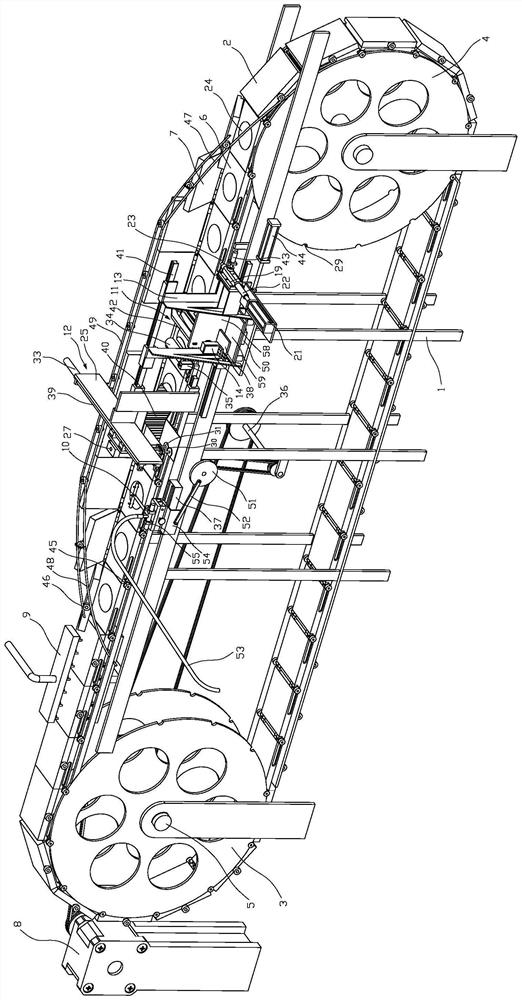

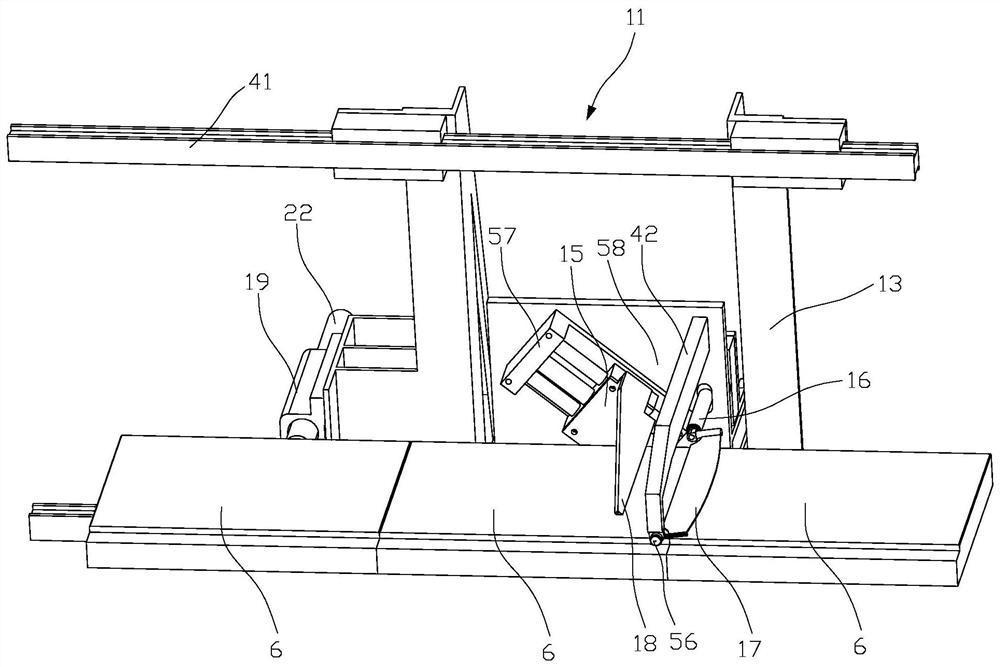

[0040] The following is attached Figure 1-5 The present invention is described in further detail.

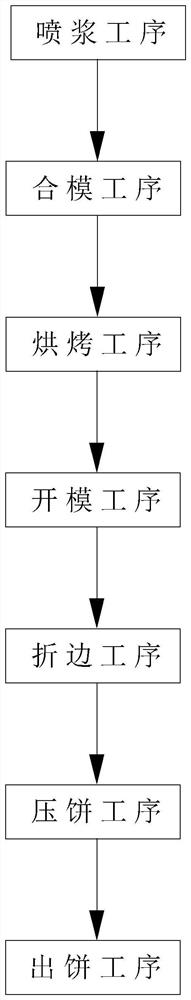

[0041] refer to figure 1 with figure 2 , the embodiment of the present invention discloses a continuous processing method for egg rolls. The processing method is completed by continuous egg roll processing equipment. The continuous egg roll processing equipment includes a long table frame 1 and a plurality of The two ends of the pressing mold 2 and the long table-top frame 1 are respectively rotated and installed with a driving wheel 3 and a passive wheel 4, and the driving wheel 3 is driven to run by a reduction motor 8. The pressing mold 2 includes a lower template 6 and an upper template 7. The lower template 6 of the same pressing mold 2 is hinged to the right side of the upper template 7, and the ends of the lower templates 6 of two adjacent pressing molds 2 are hinged in turn. A circular transmission chain is formed, and the outer edges of the driving wheel 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com