Locking type material box

A material box, lock technology, applied in the field of transportation, can solve the problem of the material slipping out of the assembly slot and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

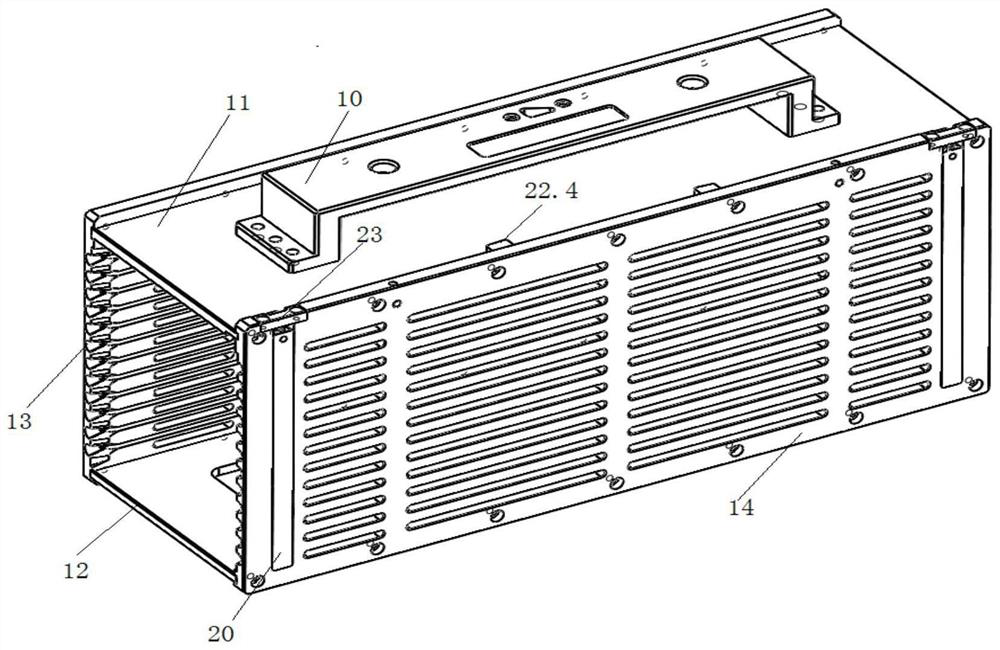

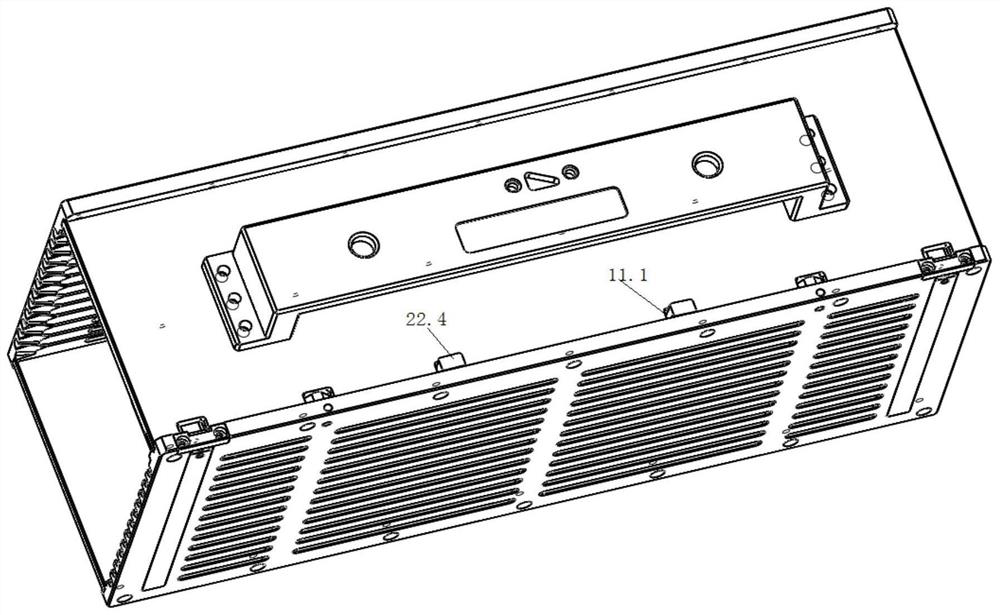

[0027] As shown in the figure: a lock-type material box, such as Figure 1-7 As shown, the cartridge body 10 is included, and the cartridge body includes a cartridge top plate 11, a cartridge bottom plate 12 and a cartridge side plate;

[0028] Wherein the top of the magazine and the bottom of the magazine are arranged correspondingly respectively, and the side panels of the magazine include a left side panel 13 and a right side panel 14, which connect the two sides of the top of the magazine and the bottom of the magazine respectively;

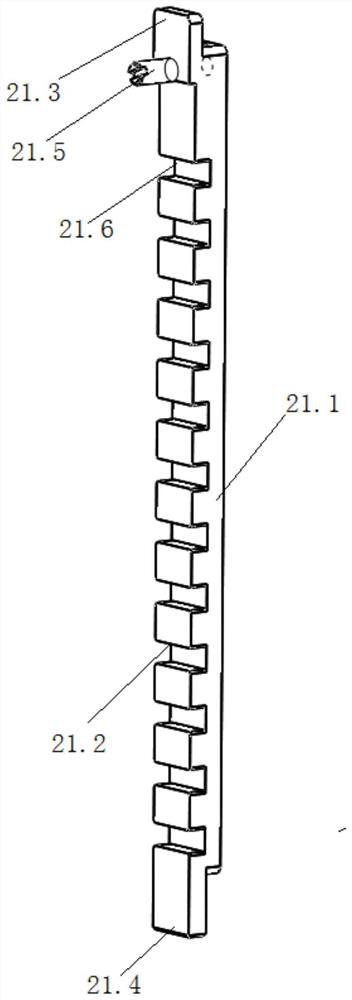

[0029] The front and rear ends of the right side plate 14 are equipped with a lock assembly 20, which includes a lock bar 21, a connecting rod assembly 22 and an auxiliary locking device 23,

[0030] Wherein the top of the right side plate 14 of the material box is embedded with a lock auxiliary device 23, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com