A rolling force compensation method and system suitable for cold tandem rolling mill

A technology of cold tandem rolling unit and compensation method, which is applied in the direction of rolling force/roll gap control, etc., can solve problems that have not been raised, and achieve the effects of improving production efficiency and quality, ensuring stability and shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

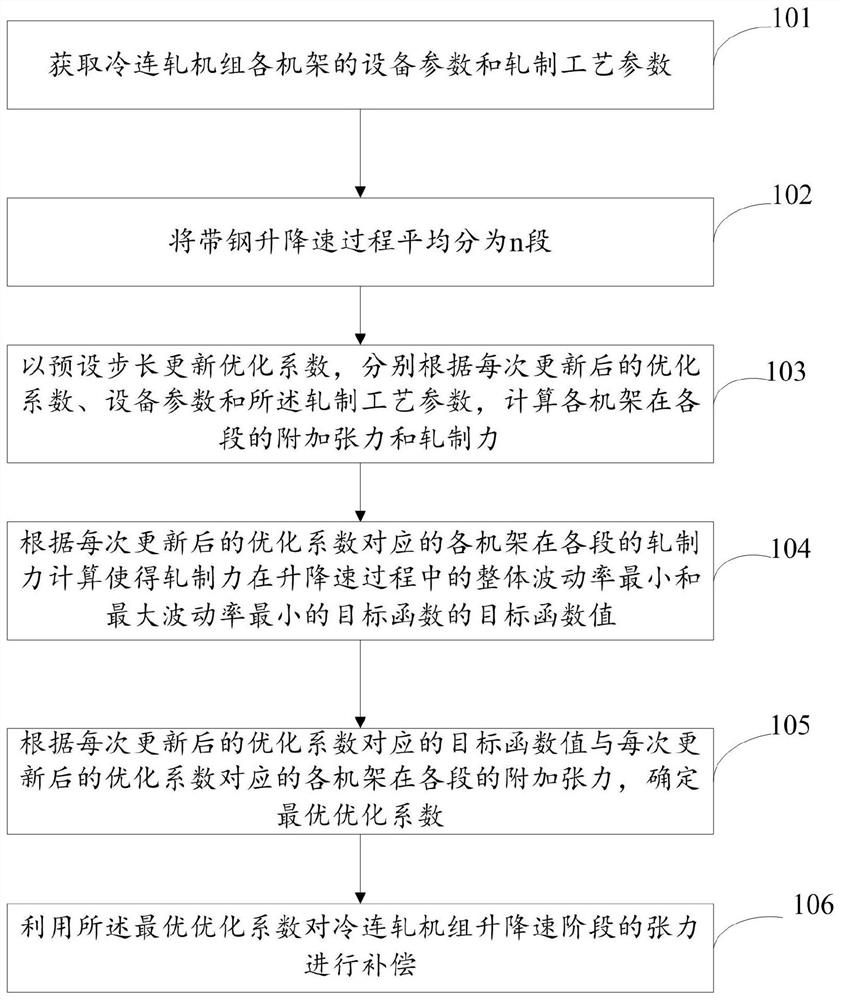

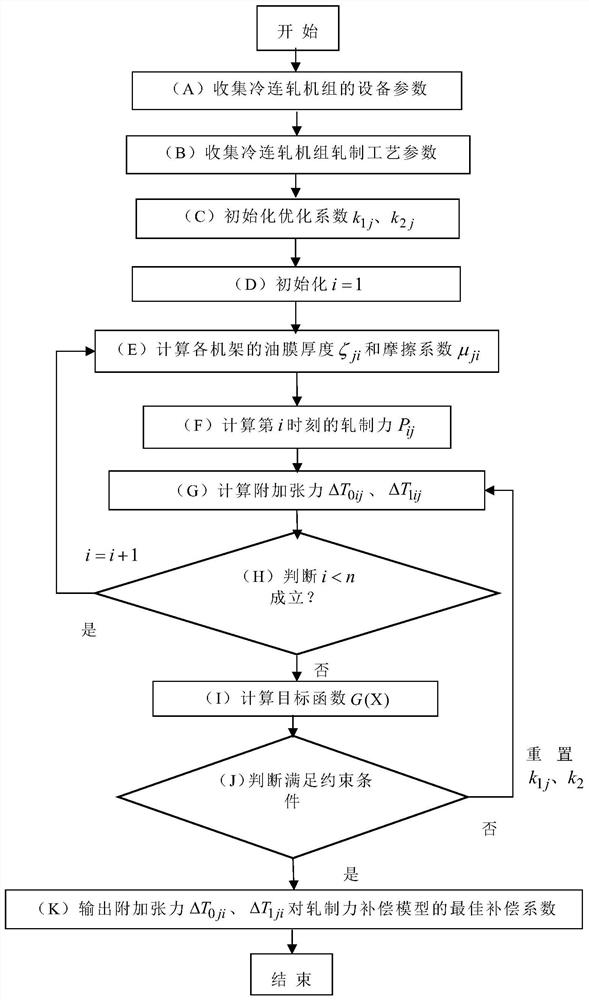

Method used

Image

Examples

Embodiment 1

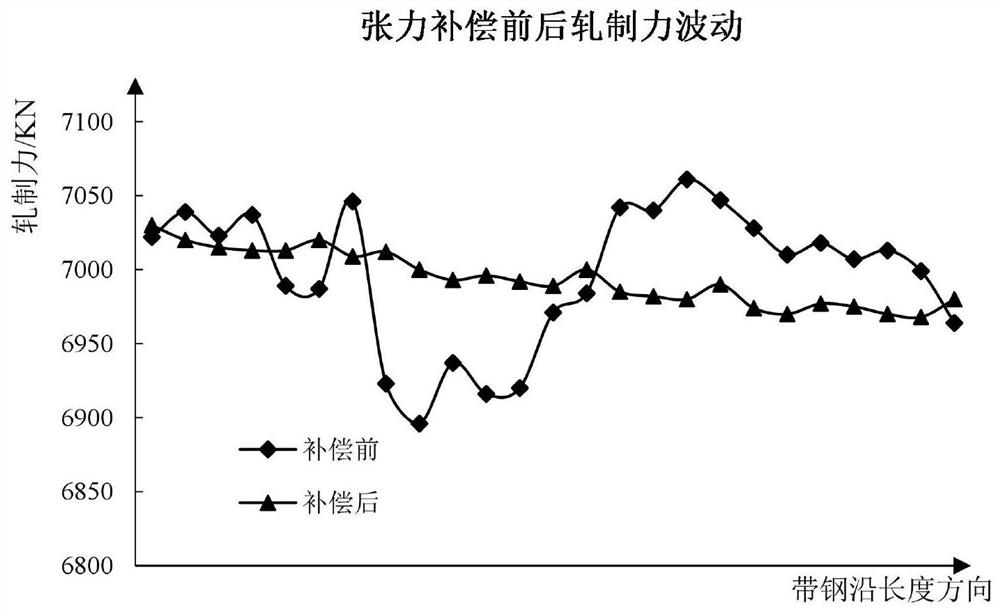

[0103] Embodiment 1: The steel type is DQ0133D1, and the specification is 1549mm×0.64mm (width×thickness)

[0104] Firstly, in step (A), the equipment parameters of each stand of the cold tandem mill are collected: work roll diameter d w =430mm, intermediate roll diameter d c =505mm, support roller diameter d b =1295mm, maximum rolling force P max =21000KN, working roll body length l w =1850mm, the length of the middle roll body l c =1885mm, the length of the back-up roller body l b =1850mm, work roll bearing housing center distance L w =4070mm, center distance L of bearing housing of intermediate roller c =4070mm, support roller bearing seat center distance L b =4070mm, work roll elastic modulus E=210Gpa, work roll Poisson's ratio ν=0.3;

[0105] Then in step (B), collect the rolling process parameters of each stand of the five-stand cold tandem rolling unit, get i=1; the rolling pressure setting value of the 1st-5th stand KN; 1-5 frame strip reduction ε j ={38%, 3...

Embodiment 2

[0129] Embodiment 2: The steel type is DT0143D9, and the specification is 1370mm×0.8mm (width×thickness)

[0130] Firstly, in step (A), the equipment parameters of each stand of the cold tandem mill are collected: work roll diameter d w =430mm, intermediate roll diameter d c=505mm, support roller diameter d b =1295mm, maximum rolling force P max =21000KN, working roll body length l w =1850mm, the length of the intermediate roll body l c =1885mm, the length of the back-up roller body l b =1850mm, work roll bearing housing center distance L w =4070mm, center distance L of bearing housing of intermediate roller c =4070mm, center distance of support roller bearing housing L b =4070mm, work roll elastic modulus E=210Gpa, work roll Poisson's ratio ν=0.3;

[0131] Then in step (B), collect the rolling process parameters of each stand of the five-stand cold tandem rolling mill, get i=1; the 1-5th stand rolling pressure setting value KN; 1-5 frame strip reduction ε j ={31.4%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com