Preparation method of glyphosate isopropylamine salt aqueous solution

A technology for glyphosate isopropylamine salt and isopropylamine, which is applied in the field of preparation of glyphosate isopropylamine salt solution, can solve the problems of flammability and volatility, poor performance of isopropylamine salt, high preparation process requirements, etc. , The effect of reducing surface tension and stabilizing process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

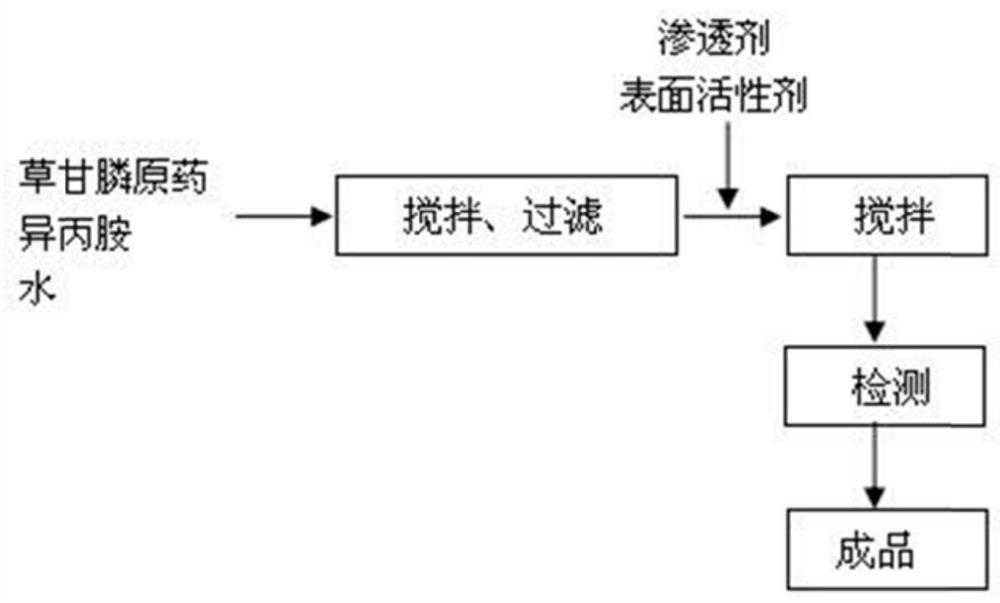

[0023] Cooperate figure 1 Shown, the invention provides a kind of preparation method of glyphosate isopropylamine saline solution, comprises the steps:

[0024] Step 1, add glyphosate technical substance and isopropylamine with a molar ratio of 1:1 to 1.2 into the reactor, and add water into the reactor, the weight ratio of water to the aforementioned mixture is 3 to 5:1, mix and stir After uniformity, adjust the temperature of the reactor to 10-20°C and keep it for 20-45 minutes;

[0025] In the step 1, each ingredient can be mixed and stirred at one time, or can be added in batches;

[0026] Step 2, pour out the mixture obtained in step 1, and filter through a 100-180-mesh filter screen, and then put the filtered mixture into the reaction kettle;

[0027] Step 3, continue to add additives and water to the reaction kettle. At this time, the mass ratio of the added additives and water to the mixture is 1.5-3:7-10:1. Adjust the temperature of the reactor to 12-23°C and stir ...

Embodiment 1

[0029] Step 1, add glyphosate technical substance and isopropylamine with a molar ratio of 1:1.1 into the reactor at one time, and add water with a weight ratio of 3:1 to the aforementioned mixture in the reactor, mix and stir evenly, Adjust the temperature of the reactor to 10°C and keep it for 45 minutes;

[0030] Step 2, pour out the mixture obtained in step 1, and filter through a 120-mesh filter, and then put the filtered mixture into the reactor;

[0031] Step 3, continue to add ST-90 penetrant and water to the reactor, the mass ratio of ST-90 penetrant and water to the mixture added at this time is 1.5:8:1, adjust the temperature of the reactor to 20°C, stir 5min to obtain glyphosate isopropylamine saline solution.

Embodiment 2

[0033] Step 1, add glyphosate technical substance and isopropylamine with a molar ratio of 1:1 into the reactor, and add water with a weight ratio of 4:1 to the aforementioned mixture in the reactor, mix and stir evenly, and then react Adjust the temperature of the kettle to 12°C and keep it for 40 minutes; then add glyphosate technical substance and isopropylamine with a molar ratio of 1:1.15 into the reaction kettle, and then add glyphosate technical substance with a molar ratio of 1:1.15 Water with a weight ratio of 4:1 to isopropylamine, keep the temperature of the reactor at 12°C for 20 minutes;

[0034] Step 2, pour out the mixture obtained in step 1, and filter through a 110-mesh filter screen, and then put the filtered mixture into the reactor;

[0035] Step 3, continue to add TAE surfactant and water to the reactor, the mass ratio of the added TAE surfactant and water to the mixture is 1.5:10:1, adjust the temperature of the reactor to 23°C, stir for 7min, Obtain gly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com