Cloud, fog and edge end cooperative bearing state monitoring and management method and system

A management method and an edge-end technology, applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as inability to accurately predict maintenance functions, data transmission pressure, and real-time feedback of monitored equipment. Achieve the effect of fast processing, reduced calculation burden and data transmission burden, and high data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

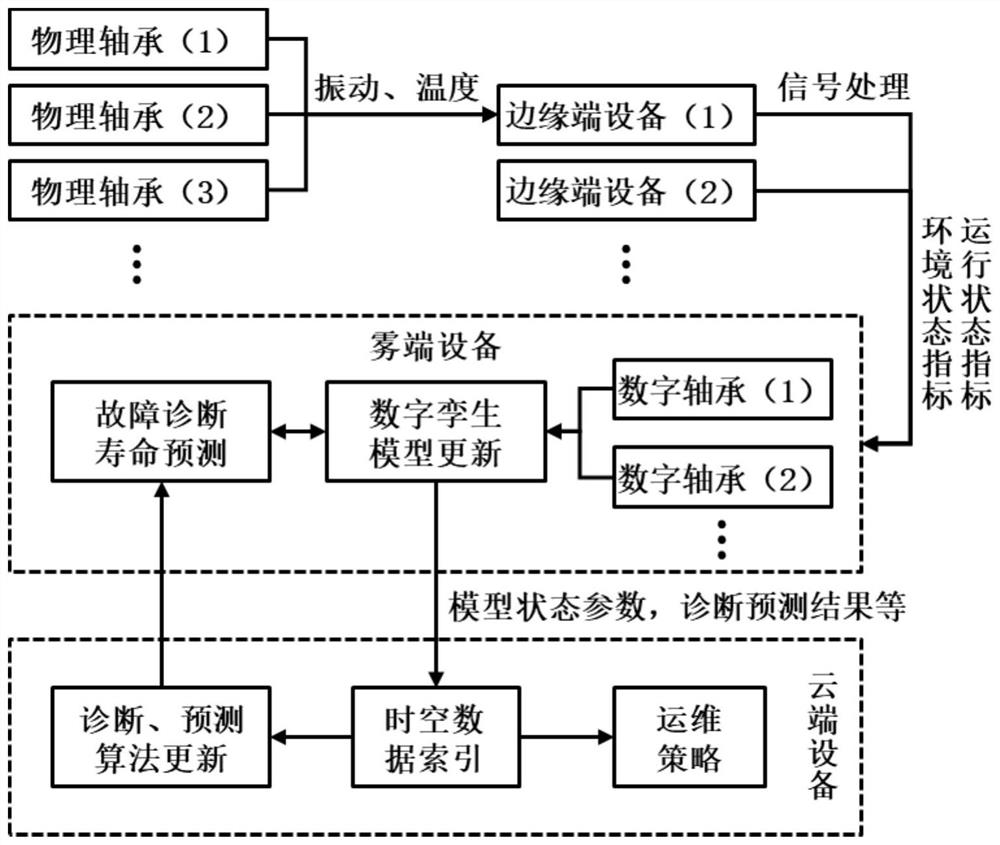

[0033]Most of the existing bearing condition monitoring and management systems based on big data technology are deployed on the cloud platform. Although the powerful computing power and data storage capacity of the cloud platform can be utilized, there are disadvantages of high information transmission pressure and poor real-time feedback to the underlying equipment. In recent years, the cloud-edge collaboration solution, which has emerged in recent years, uses edge computing technology to realize the processing and feature extraction of the original test signal at the terminal, which reduces the pressure on information transmission and improves the real-time feedback of the underlying equipment. However, for fault diagnosis of regional equipment clusters and life prediction customized model training, this solution cannot be solved well. In addition, the existing clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com