Transverse air intake and exhaust distribution device

A technology of intake and exhaust, horizontal placement, applied in the direction of valve devices, lift valves, mechanical equipment, etc., can solve the problem that the arrangement of intake and exhaust valves is difficult to meet the experimental requirements, and achieve the effect of improving the intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

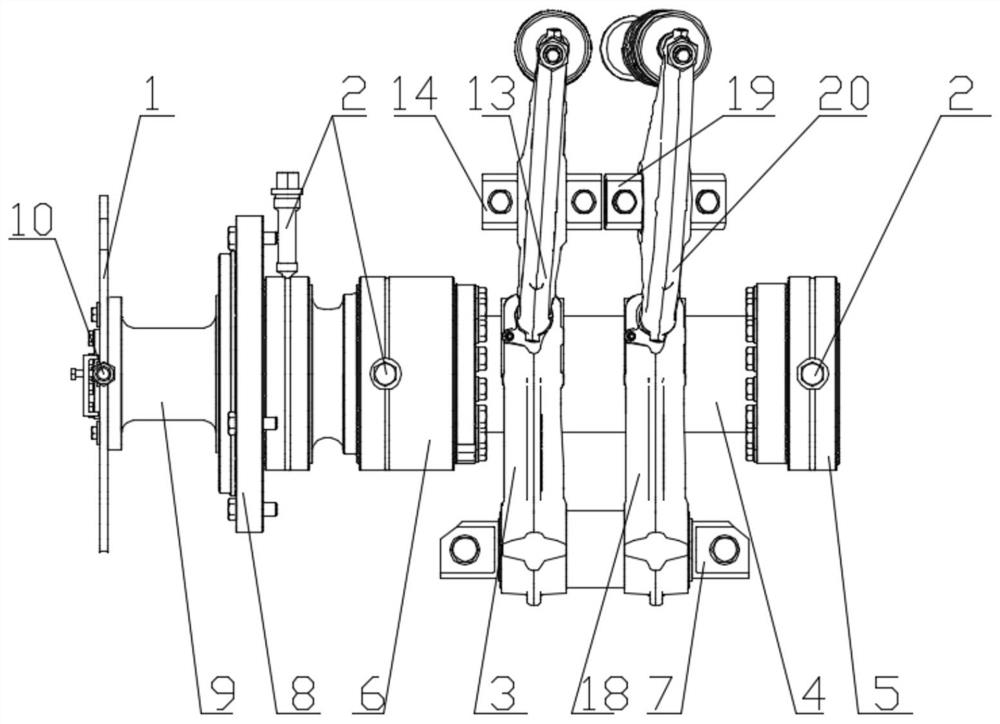

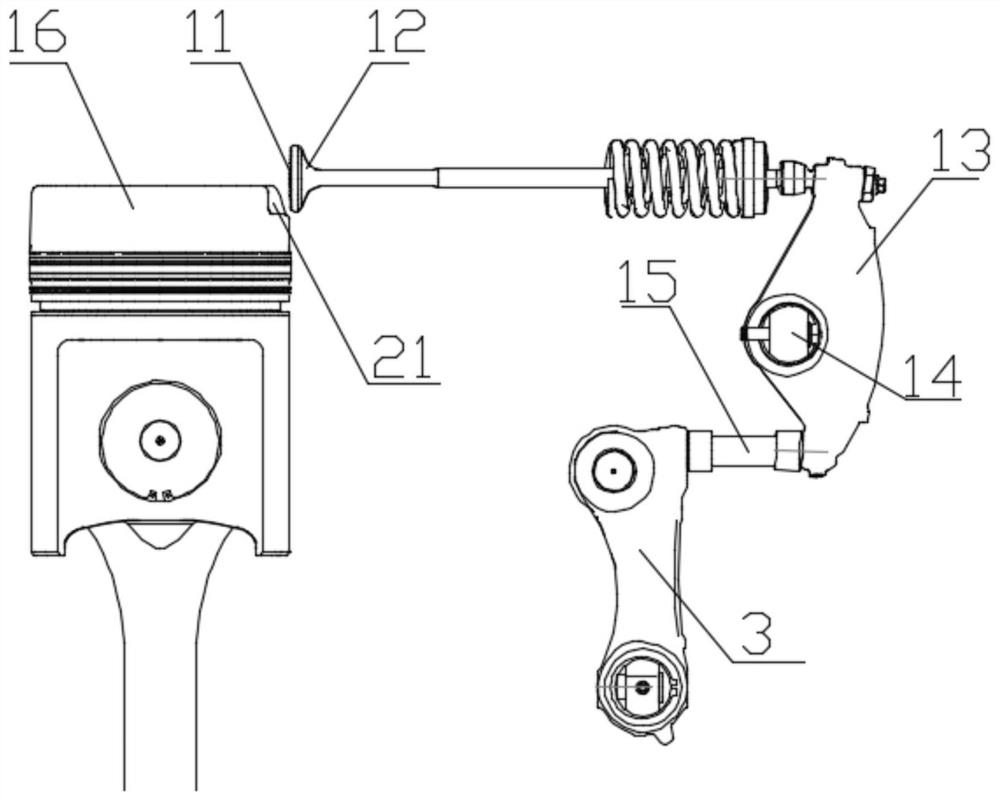

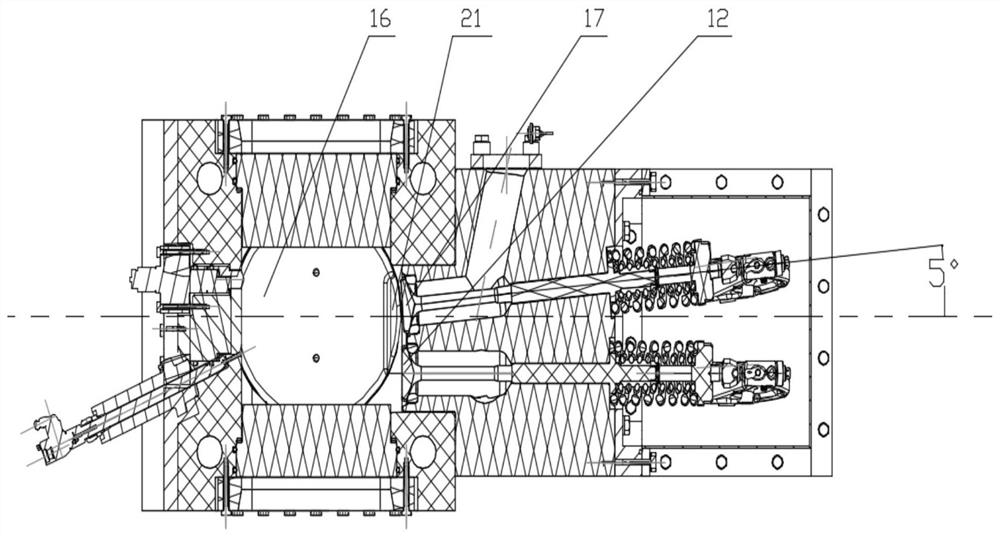

[0019] see Figure 1-3 Describe this embodiment, a horizontal intake and exhaust gas distribution device, which includes a camshaft 4, a driven shaft 7, an intake valve 17, an exhaust valve 12, an intake cam follower 18, an exhaust cam follower Part 3, intake rocker arm 20, exhaust rocker arm 13, intake push rod and exhaust push rod 15, intake cam and exhaust cam are installed on the camshaft 4, and the intake cam and exhaust The cams are in contact with the intake cam follower 18 and the exhaust cam follower 3 respectively, and the bottom ends of the intake cam follower 18 and the exhaust cam follower 3 are connected to the driven shaft 7 in rotation, The upper part of the intake cam follower 18 is connected to the bottom of the intake rocker arm 20 through the intake push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com