Brush head and garment steamer

A brush body and brush hole technology, which is applied in the field of garment steamers, can solve the problems of affecting user experience and prone to omission of brush heads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

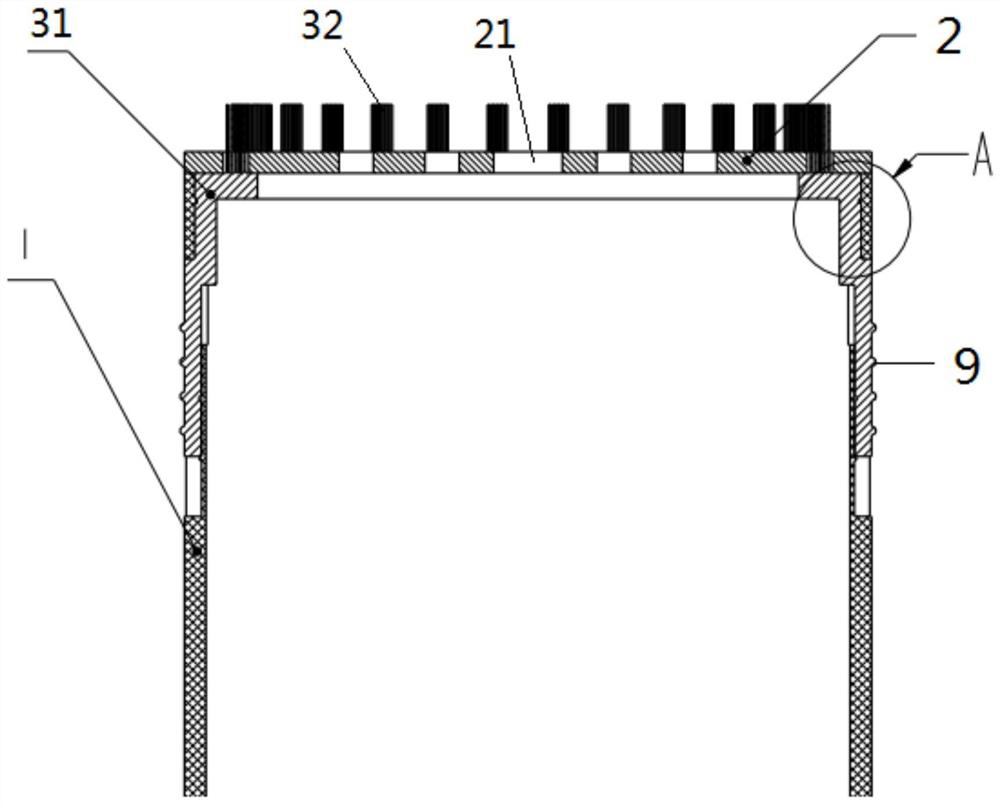

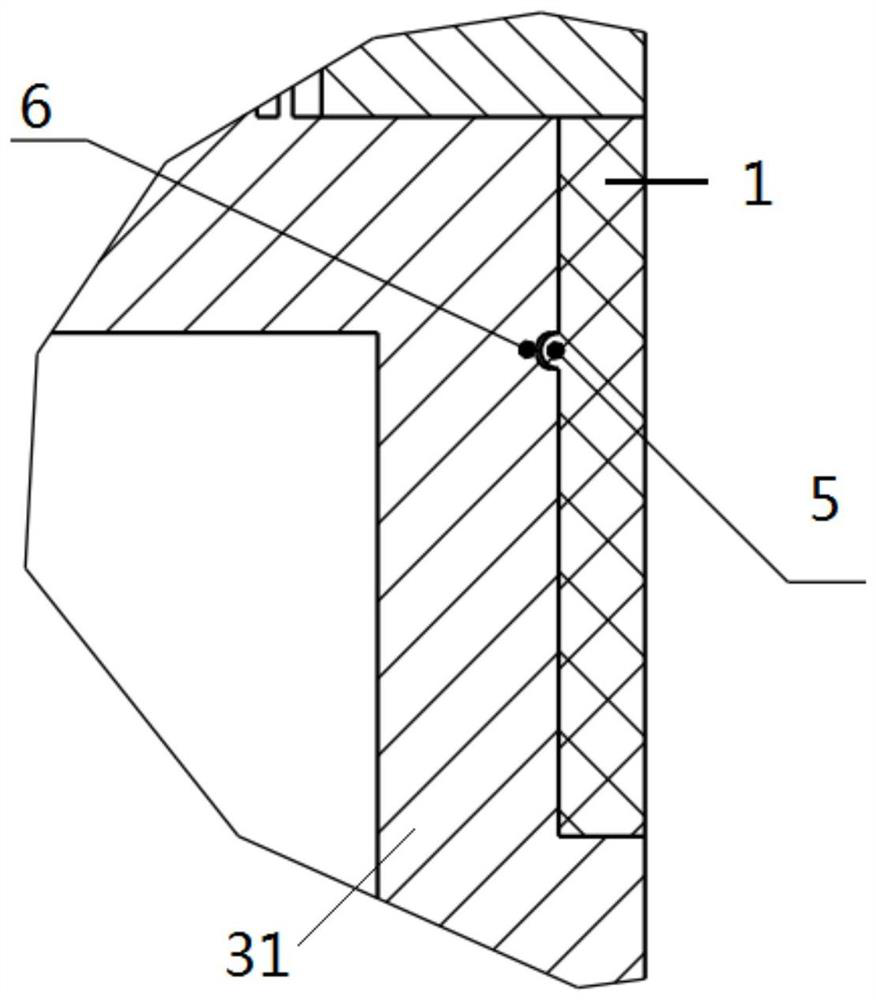

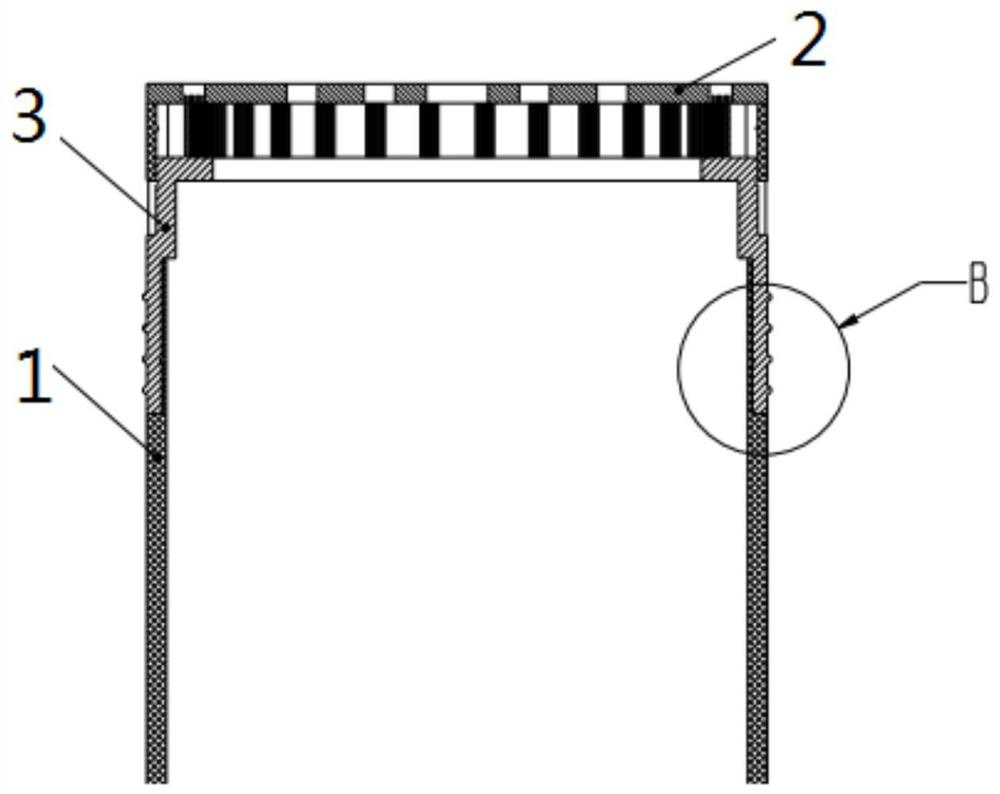

[0036] This embodiment provides a brush head. The brush head itself can be applied to a garment steamer or an iron, such as Figure 1-Figure 7 shown, including:

[0037] The housing 1 is provided with an accommodating cavity inside, and the side wall of the housing 1 is provided with a chute;

[0038] Specifically, the casing 1 itself is made of plastic material, and an accommodation chamber is provided inside the casing 1, and the accommodation chamber itself forms a space for steam to flow. In this embodiment, the shape of the housing 1 itself is not limited, and it can be arranged in a regular shape, such as a cylinder or a cuboid, or in an irregular shape.

[0039] At the same time, the structure of the chute is not limited, and one chute itself can be provided. As a deformation, multiple sets of chute can also be provided on the casing 1, such as Figure 6 As shown, the chute is arranged in two groups, and the chute of the two groups is arranged oppositely. During the d...

Embodiment 2

[0061] This embodiment provides a garment ironing machine, comprising: a water tank, on which a water pipe is arranged;

[0062] The brush head provided in Embodiment 1 is connected to the other end of the water pipe.

[0063] Specifically, the water pipe itself is arranged flexibly, and the brush head itself can move freely through the upper arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com