Online production coke oven combustion chamber furnace end sealing method

A technology of combustion chamber and burner head, which is applied to the door/closure of coke oven, coke oven, heating of coke oven, etc. It can avoid the overflow of waste gas, put an end to the overflow of waste gas, and protect the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

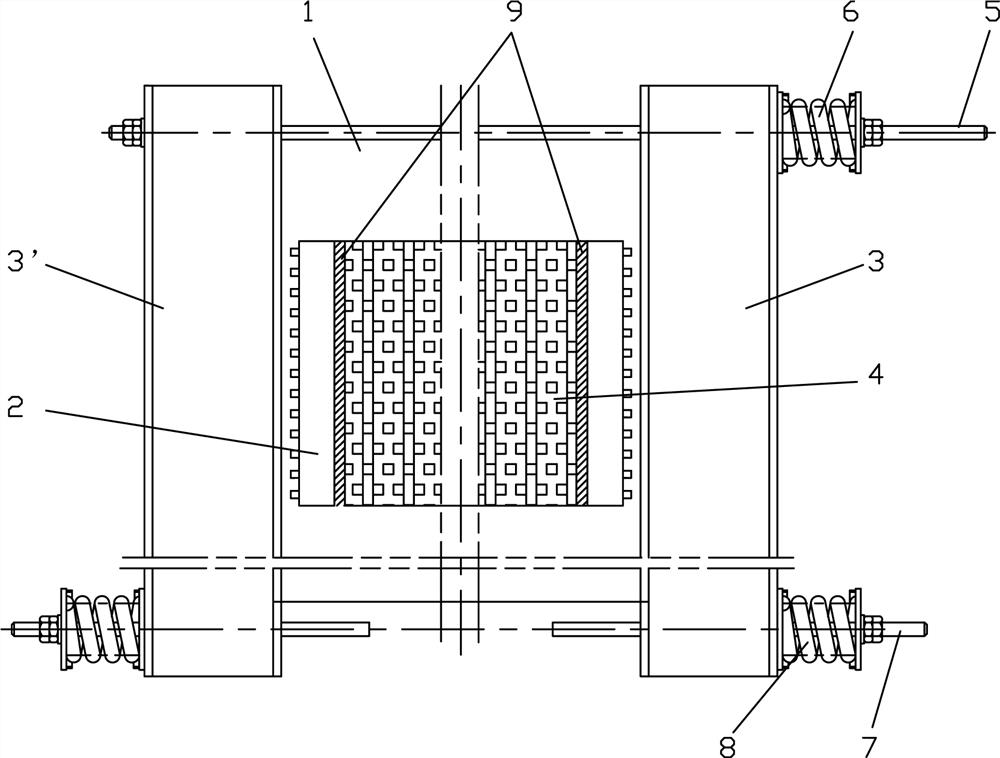

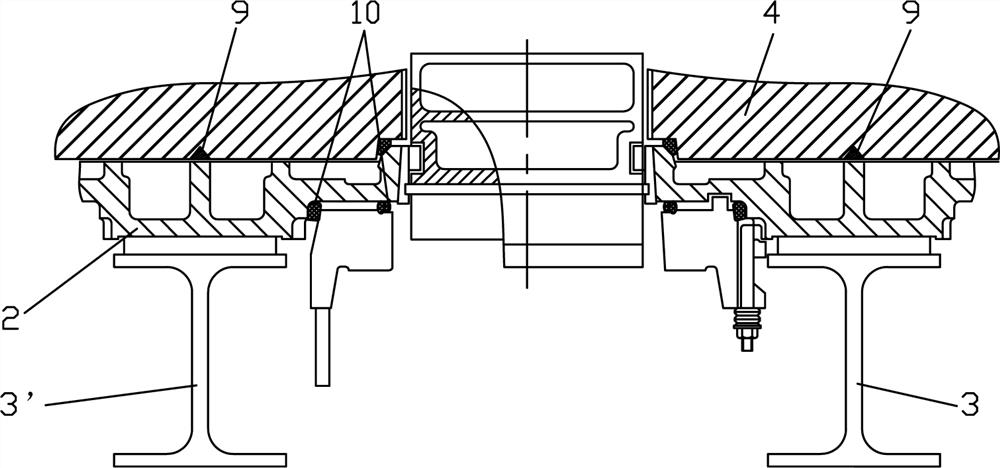

[0036] see figure 1 , figure 2 , the on-line production coke oven burner head sealing method of the present invention, it comprises the steps:

[0037] 1) Drilling holes in the burner head of the combustion chamber

[0038] Determination of the drilling position: first remove the burner brick on the upper part of the coke oven 1 combustion chamber on the upper part of the broken large protective plate 2, and use the position of the grouting hole between the large protective plate 2 and the furnace head during furnace construction to drill holes, according to the size of the grouting hole The size of the drill hole diameter is determined by the size of the drill hole, and the drill hole depth is determined according to the coke oven type, the smoking part of the furnace head and the break position of the large protective plate, but the maximum depth of the drill hole cannot exceed the bottom of the large protective plate 2;

[0039] 2) Combustion chamber burner air pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com