Method for improving jelly strength of gelatin

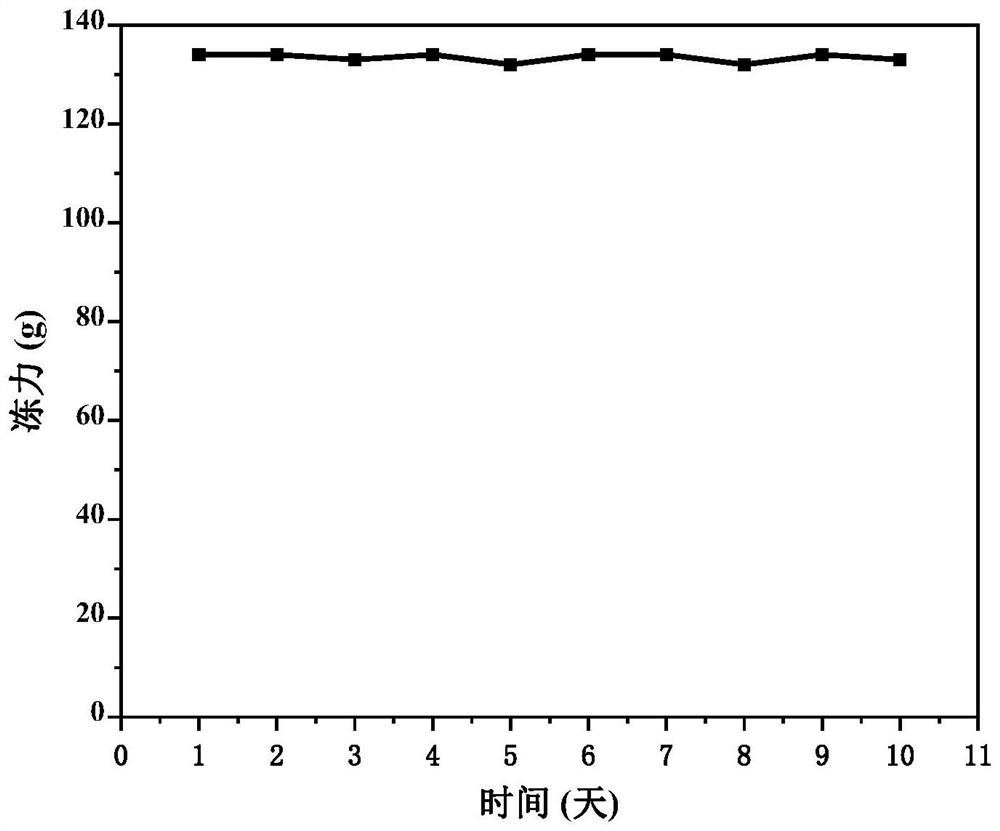

A technology of gelatin and freezing force, applied in the field of gelatin preparation, can solve the problems of complicated operation, high cost and the like, and achieve the effects of simple operation, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of method of improving gelatin freezing force of the present invention is specifically implemented according to the following steps:

[0040] Modification: Weigh 10g of industrial gelatin, 0.01g of cationic modifier, add 140mL of deionized water, blend evenly and pour into a 250mL plastic bottle to prepare a 150mL gelatin solution with a concentration of 6.67%. The reaction was carried out in a constant temperature shaker at 40° C. for 2 h. After the reaction, the glue was left to stand at 80° C. for 4 hours to inactivate the enzyme.

[0041] Filtration: Pour the modified glue solution into a filter for filtration. Filtration time is 2h.

[0042] Concentration: Pour the filtered glue solution into a double-effect vacuum dryer for concentration, so that the glue solution mass concentration reaches 20%-25%, and then sterilize at 142°C for 3-5s. The evaporation concentration temperature is 75°C and the time is 12h.

[0043] Freeze forming: send the concentrated ...

Embodiment 2

[0046] A kind of method of improving gelatin freezing force of the present invention is specifically implemented according to the following steps:

[0047] Modification: Weigh 10g of gelatin, 0.03g of cationic modifier, add 140mL of deionized water, blend evenly and pour into a 250mL plastic bottle to prepare a 150mL gelatin solution with a concentration of 6.67%. The reaction was carried out in a constant temperature shaker at 40° C. for 3 h. After the reaction, the glue was left to stand at 80° C. for 4 hours to inactivate the enzyme.

[0048] Filtration: Pour the modified glue solution into a filter for filtration. Filtration time is 2.5h.

[0049] Concentration: Pour the filtered glue solution into a double-effect vacuum dryer for concentration, so that the glue solution mass concentration reaches 20%-25%, and then sterilize at 142°C for 3-5s. The evaporation concentration temperature is 80°C and the time is 14h.

[0050] Freeze forming: send the concentrated glue to t...

Embodiment 3

[0053] A kind of method of improving gelatin freezing force of the present invention is specifically implemented according to the following steps:

[0054] Modification: Weigh 10g of gelatin, 0.05g of cationic modifier, add 140mL of deionized water, blend evenly and pour into a 250mL plastic bottle to prepare a 150mL gelatin solution with a concentration of 6.67%. React in a constant temperature shaker at 40°C for 2h. After the reaction, the glue was left to stand at 80° C. for 4 hours to inactivate the enzyme.

[0055] Filtration: Pour the modified glue solution into a filter for filtration. Filtration time is 3h.

[0056]Concentration: Pour the filtered glue solution into a double-effect vacuum dryer for concentration, so that the glue solution mass concentration reaches 20%-25%, and then sterilize at 142°C for 3-5s. The evaporation concentration temperature was 82°C and the time was 16h.

[0057] Freeze forming: send the concentrated glue to the extruder for freezing an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com