Textile fabric processing winding device capable of preventing cloth from being folded

A textile fabric and fabric folding technology, applied in the field of textile processing, can solve the problems of reducing the quality of finished products, affecting the effect of finished products, affecting the processing of fabrics, etc., to achieve the effects of reducing defective rate, improving detection accuracy, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

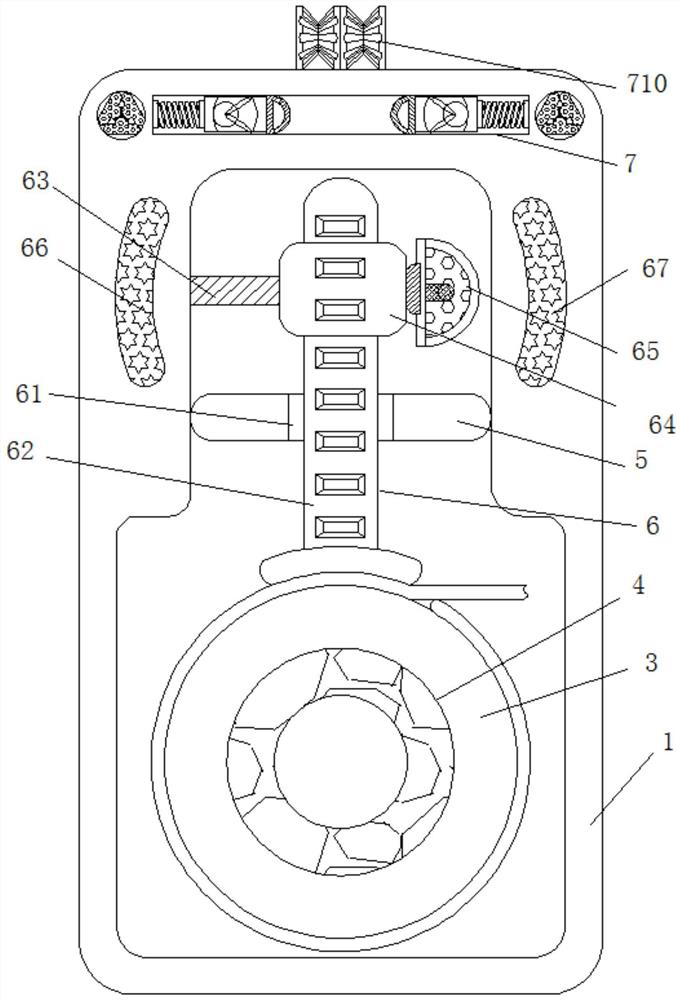

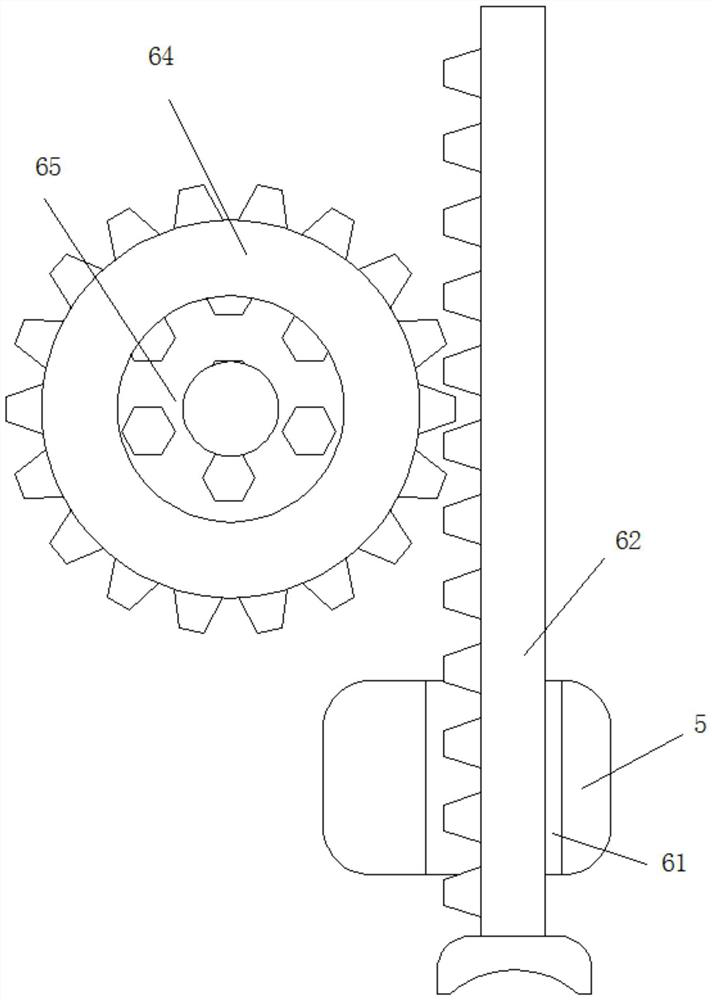

[0026] see Figure 1-3 , a winding device for textile fabric processing that prevents fabric from folding, including a device casing 1, and also includes a drive motor 2, a winding shaft 3, a speed measuring component 4, a limit plate 5, a winding detection component 6, and the device casing 1 is internally connected with drive motor 2, its model is ACSM130-G05025LZ, the back of drive motor 2 is fixedly connected with winding shaft 3, inside of winding shaft 3 is fixedly connected with speed measurement component 4, and inside of equipment shell 1 is fixedly connected with limiting plate 5. The inside of the limiting plate 5 is movably connected with a winding detection component 6;

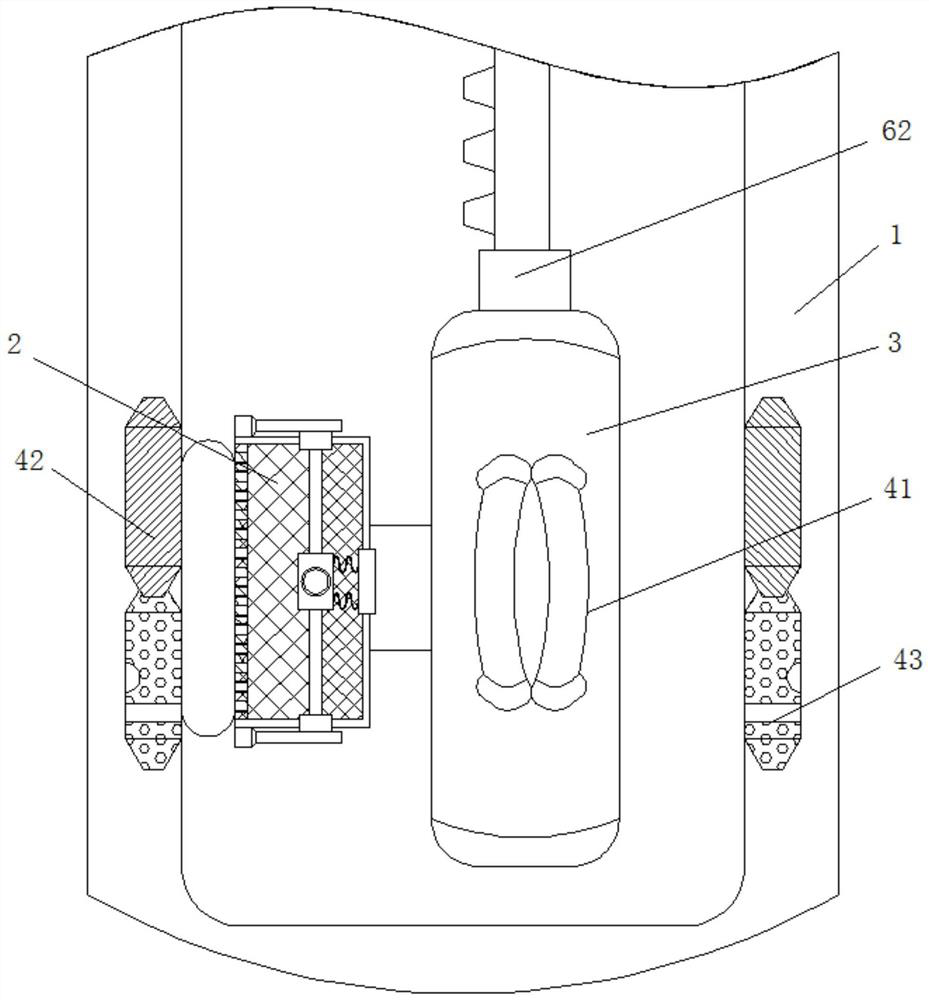

[0027] The speed measuring assembly 4 includes a first closed conductor 41, a first magnet block 42, and a second magnet block 43. The first closed conductor 41 is fixedly connected to the inside of the winding shaft 3, and the first magnet block 42 is fixedly connected to the inside of the equip...

Embodiment 2

[0030] see Figure 1-4 , a winding device for textile fabric processing that prevents fabric from folding, including a device housing 1, and also includes a drive motor 2, a winding shaft 3, a speed measuring component 4, a limit plate 5, a winding detection component 6, and a control reminder component 7. The drive motor 2 is movably connected inside the equipment shell 1, and its model is ACSM130-G05025LZ. The limiting plate 5 is fixedly connected, the winding detection component 6 is movably connected inside the limiting plate 5, and the control reminder component 7 is fixedly connected inside the equipment housing 1;

[0031] The speed measuring assembly 4 includes a first closed conductor 41, a first magnet block 42, and a second magnet block 43. The first closed conductor 41 is fixedly connected to the inside of the winding shaft 3, and the first magnet block 42 is fixedly connected to the inside of the equipment housing 1. The inside of the device housing 1 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com