Uranium conversion material automatic feeding assembly with temporary storage function

An automatic feeding and functional technology, applied in nuclear power generation, conveyor objects, color TV components, etc., can solve the problems of time-consuming and laborious operation, dust generation, powder leakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

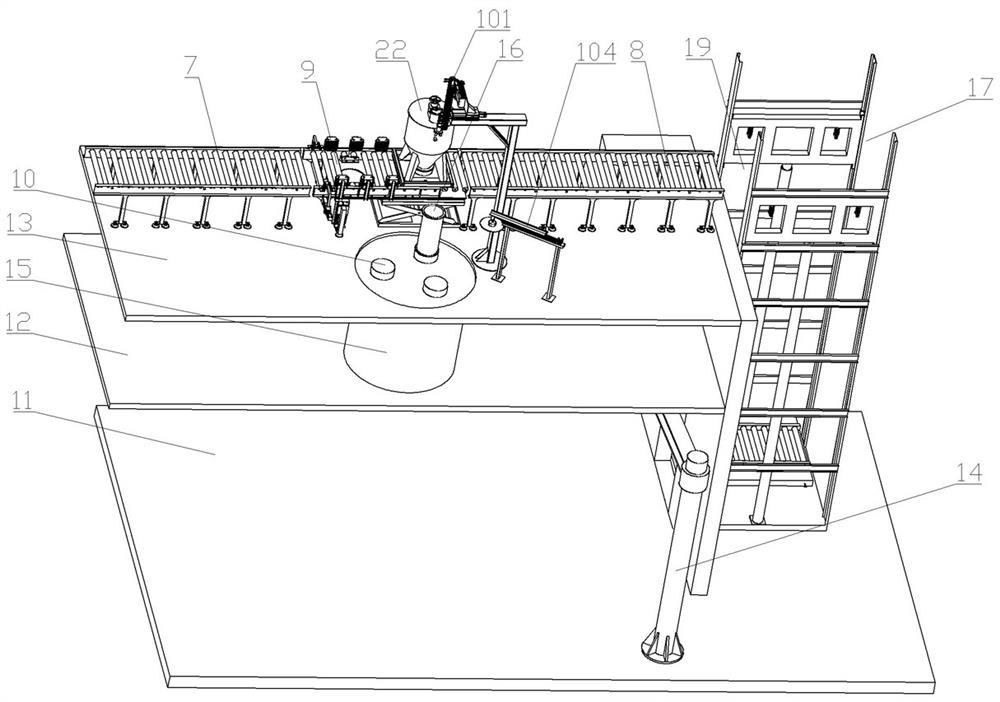

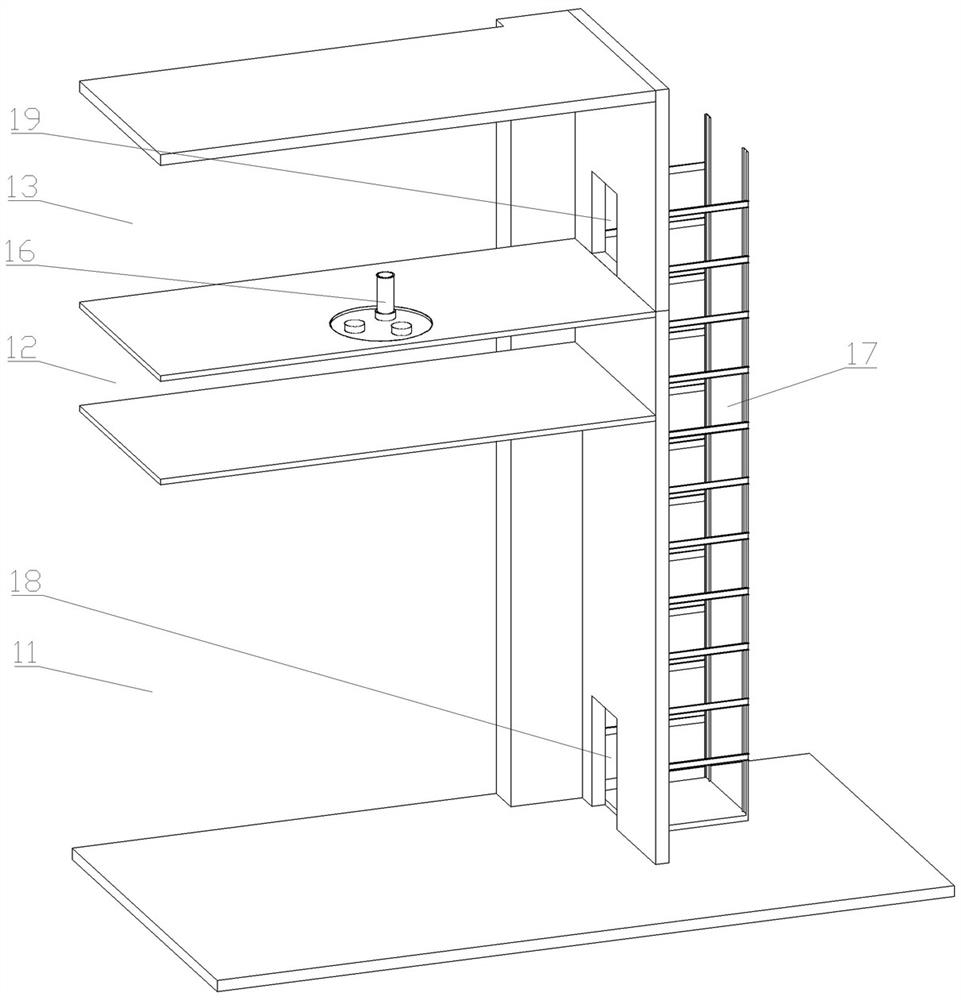

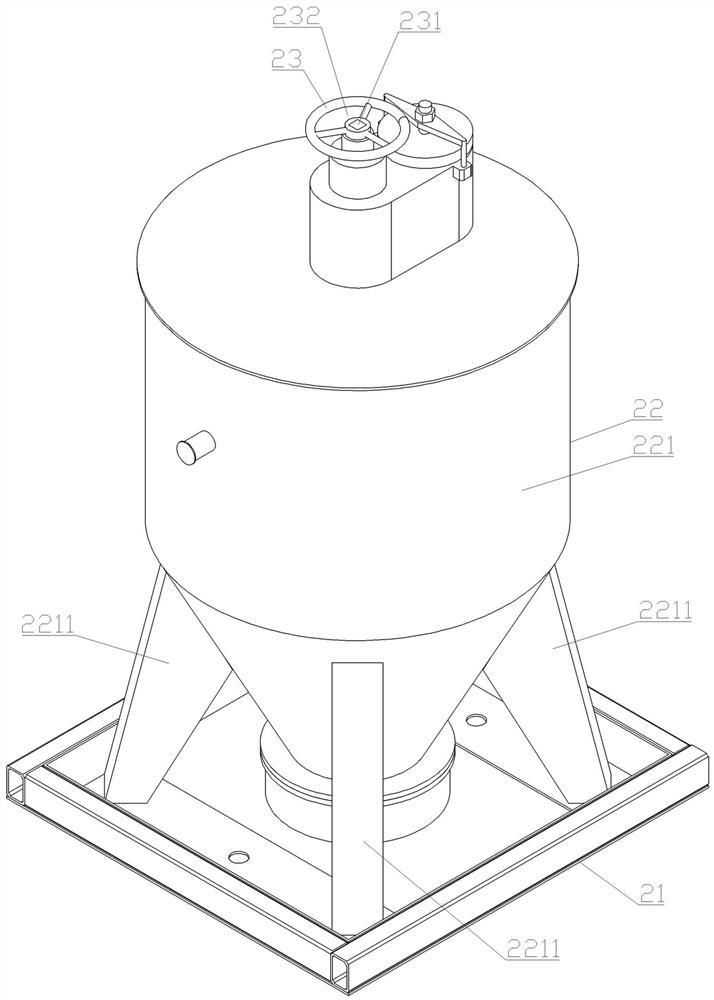

[0060] Such as Figure 1-16 As shown, the automatic feeding assembly of uranium conversion materials with cache function, including the plant. The interior of the factory building is divided into three floors in the vertical direction. From bottom to top, there are lower floor 11, middle floor 12 and upper floor 13. The lower floor 11 is equipped with a cantilever crane 14. The floor of the factory building is provided with a discharge port 16 connected to the transfer bin 15, and the factory building is provided with a lifting passage 17 passing through the lower floor 11, the middle floor 12 and the upper floor 13 at the edge of the wall, and the wall of the lower floor 11 of the factory building is provided with a connecting To the lower opening 18 at the lower end of the lift passage 17, the upper floor 19 connected to the upper end of the lift passage 16 is provided on the wall body of the factory building upper floor 13.

[0061] The automatic feeding assembly for urani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com