Transfer device for tubular building construction materials

A technology for building construction and transfer devices, which is applied in the field of building materials, and can solve problems such as bumpy road conditions, deformation, and easy paint drop at the construction site, and achieve the effect of being easy to pick up again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

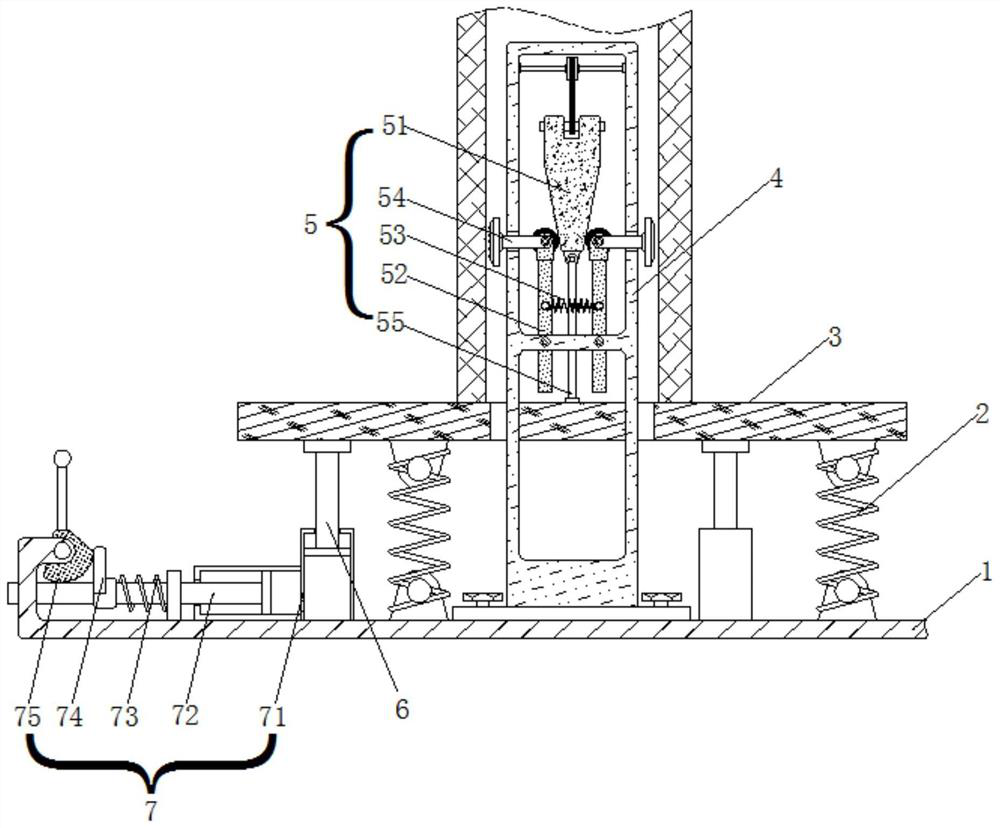

[0024] see Figure 1-2 , a device for transferring tubular building construction materials, comprising a base 1, a spring 2 is fixedly installed above the base 1, and a bearing plate 3 is movably installed at the end of the spring 2 away from the base 1, and the middle part of the bearing plate 3 is fixed and installed limitedly. The middle part of the positioning post 4 and the bearing plate 3 is provided with a through hole, and both sides of the positioning post 4 are provided with sliding grooves. A fixing mechanism 5 is fixedly installed in the middle part of the limit post 4, a piston rod 6 is fixedly installed under the bearing plate 3, and a reset mechanism 7 is fixedly installed on the side of the piston rod 6 away from the bearing plate 3.

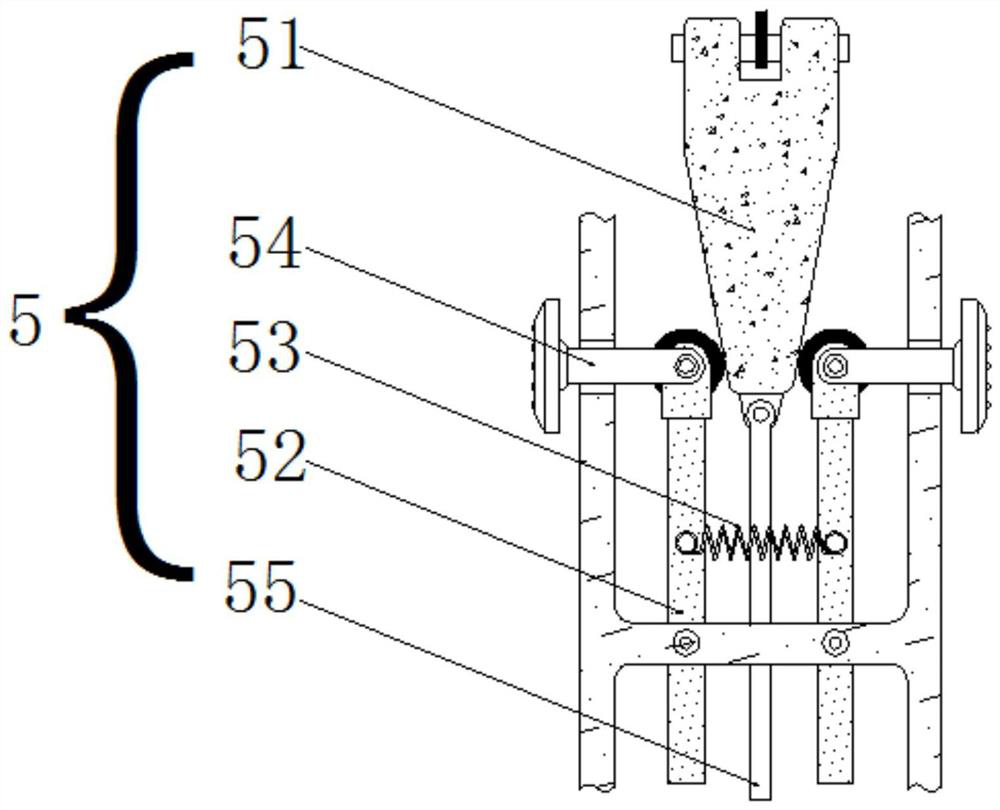

[0025] The fixing mechanism 5 includes a trapezoidal block 51 , and the end of the connecting column 55 away from the trapezoidal block 51 is fixedly connected to the middle part of the bearing plate 3 . Both sides of trapezoida...

Embodiment 2

[0027] see figure 1 , 3 , a device for transferring tubular building construction materials, comprising a base 1, a spring 2 is fixedly installed above the base 1, and a bearing plate 3 is movably installed at the end of the spring 2 away from the base 1, and the middle part of the bearing plate 3 is fixed and installed limitedly. The middle part of the positioning post 4 and the bearing plate 3 is provided with a through hole, and both sides of the positioning post 4 are provided with sliding grooves. A fixing mechanism 5 is fixedly installed in the middle part of the limit post 4, a piston rod 6 is fixedly installed under the bearing plate 3, and a reset mechanism 7 is fixedly installed on the side of the piston rod 6 away from the bearing plate 3.

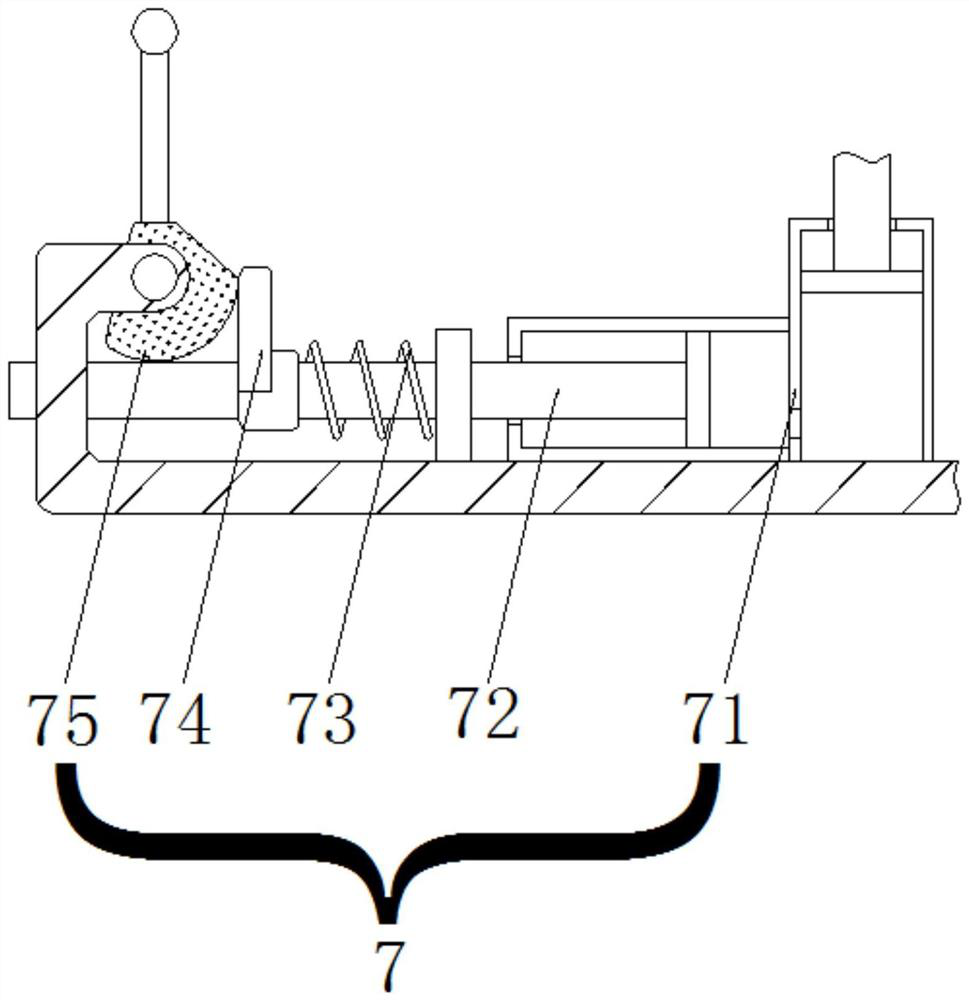

[0028] Resetting mechanism 7 comprises cylinder 71, and the left side of cylinder 71 is movablely installed with moving bar 72, and the middle part of moving bar 72 is sleeved with spring 3 73, and the end of spring 3 73 away f...

Embodiment 3

[0030] see Figure 1-3 , a device for transferring tubular building construction materials, comprising a base 1, a spring 2 is fixedly installed above the base 1, and a bearing plate 3 is movably installed at the end of the spring 2 away from the base 1, and the middle part of the bearing plate 3 is fixed and installed limitedly. The middle part of the positioning post 4 and the bearing plate 3 is provided with a through hole, and both sides of the positioning post 4 are provided with sliding grooves. A fixing mechanism 5 is fixedly installed in the middle part of the limit post 4, a piston rod 6 is fixedly installed under the bearing plate 3, and a reset mechanism 7 is fixedly installed on the side of the piston rod 6 away from the bearing plate 3.

[0031] The fixing mechanism 5 includes a trapezoidal block 51 , and the end of the connecting column 55 away from the trapezoidal block 51 is fixedly connected to the middle part of the bearing plate 3 . Both sides of trapezoida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com