Gold stamping equipment

A kind of equipment, the technology of hot stamping roller, applied in printing, rotary printing machine, printing machine and other directions, can solve the problems of short bonding time, incomplete transfer of hot stamping paper, and reduce the quality of fabric hot stamping, so as to prolong the bonding Time, reduce the probability of incomplete transfer phenomenon, improve the effect of bronzing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

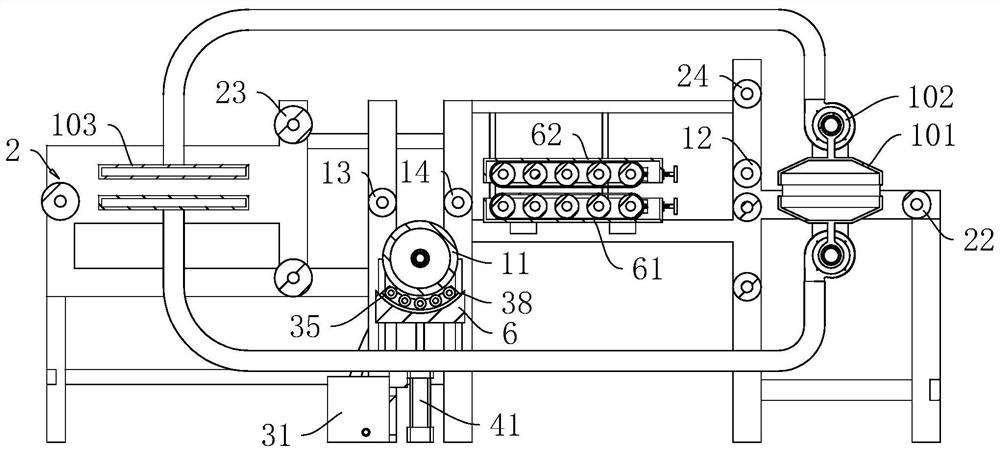

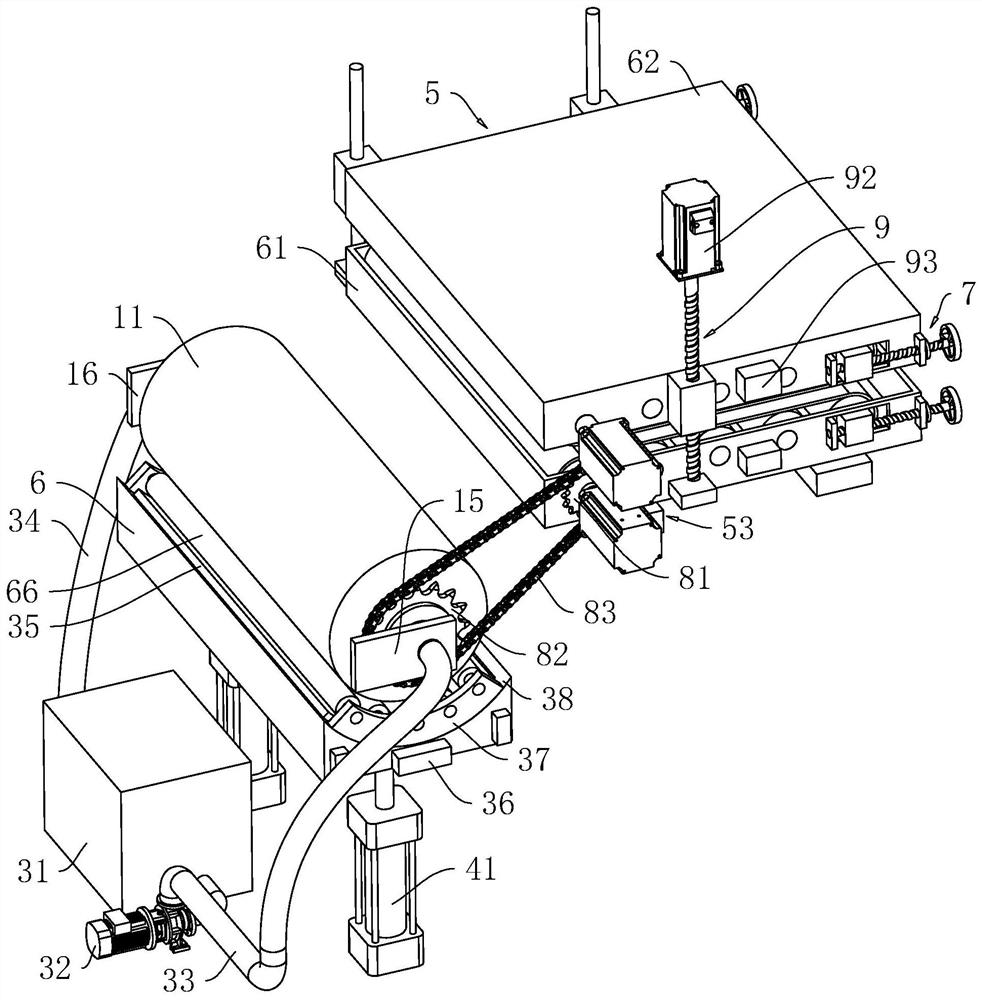

[0071] The present application will be described in further detail below in conjunction with drawings 1-5.

[0072] The embodiment of the present application discloses a bronzing device.

[0073] In the embodiment of the present application, the model of the distance sensor 93 is E3JK-DR11.

[0074] refer to figure 1 and figure 2 , the hot stamping equipment includes a frame 1, a hot stamping roller 11 horizontally hinged on the frame 1, a feeding device 2 is arranged on the frame 1, and the feeding device 2 includes a cloth roll 21, a winding roll 22, and two paper rolls 23 , Two paper delivery tubes 24.

[0075] refer to figure 1 and figure 2 , the cloth rolling roller 21 and the winding roller 22 are all horizontally hinged on the frame 1, and the cloth rolling roller 21 and the winding roller 22 are horizontally spaced apart, and the cloth rolling roller 21 and the winding roller 22 are respectively located on the two sides of the bronzing roller 11 Side and be pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com