Portable oil conveying pipe support welding and positioning tool

A technology of welding positioning tooling and oil pipelines, which is applied in the field of automotive parts, can solve problems such as low production efficiency, increase repair costs, and affect production efficiency, and achieve the effects of improving work efficiency, reducing labor intensity, and flexible and convenient operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

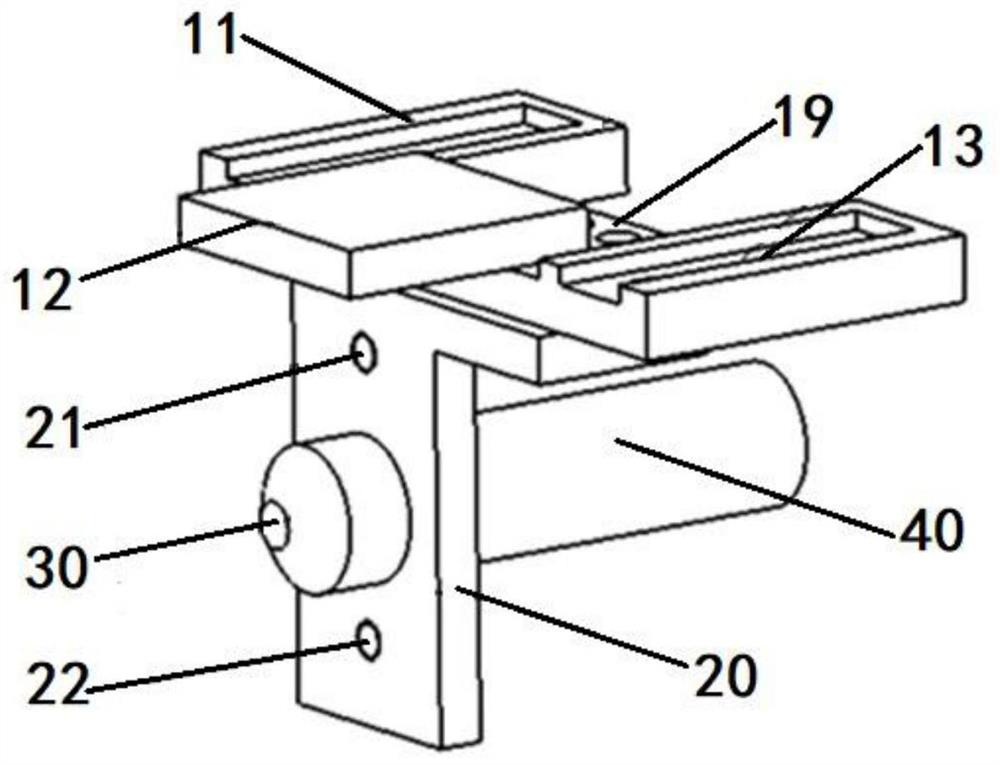

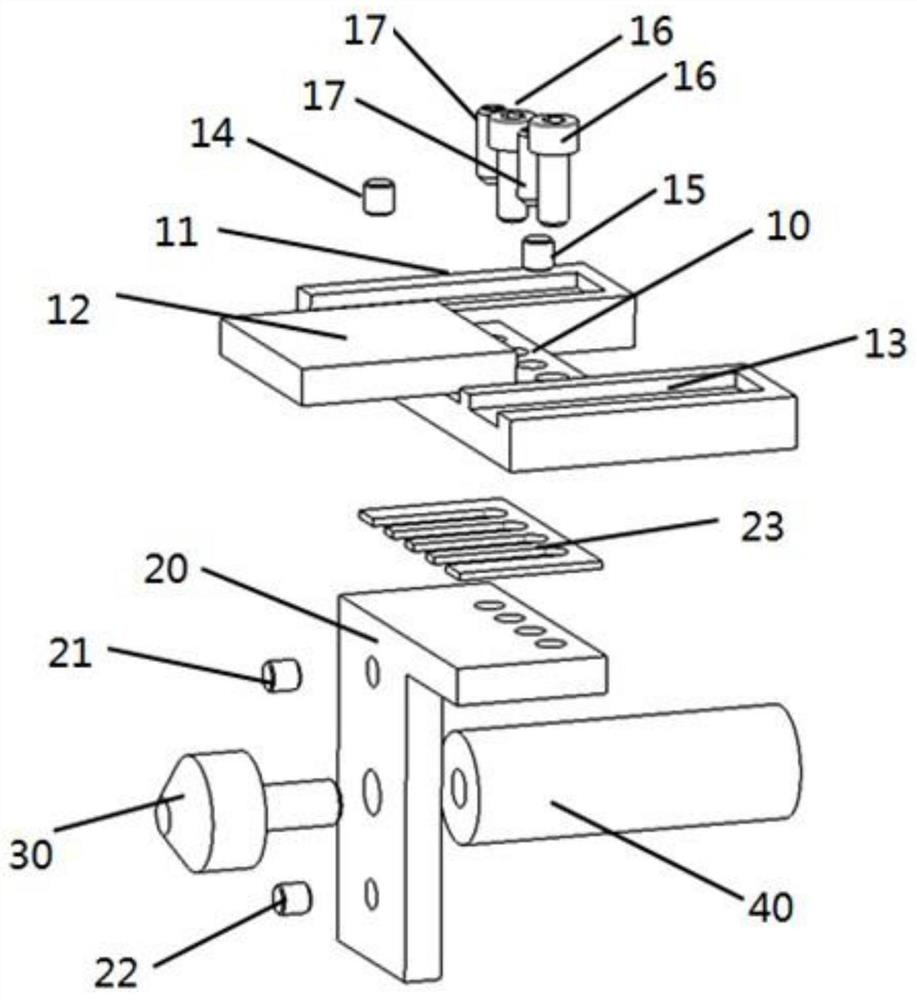

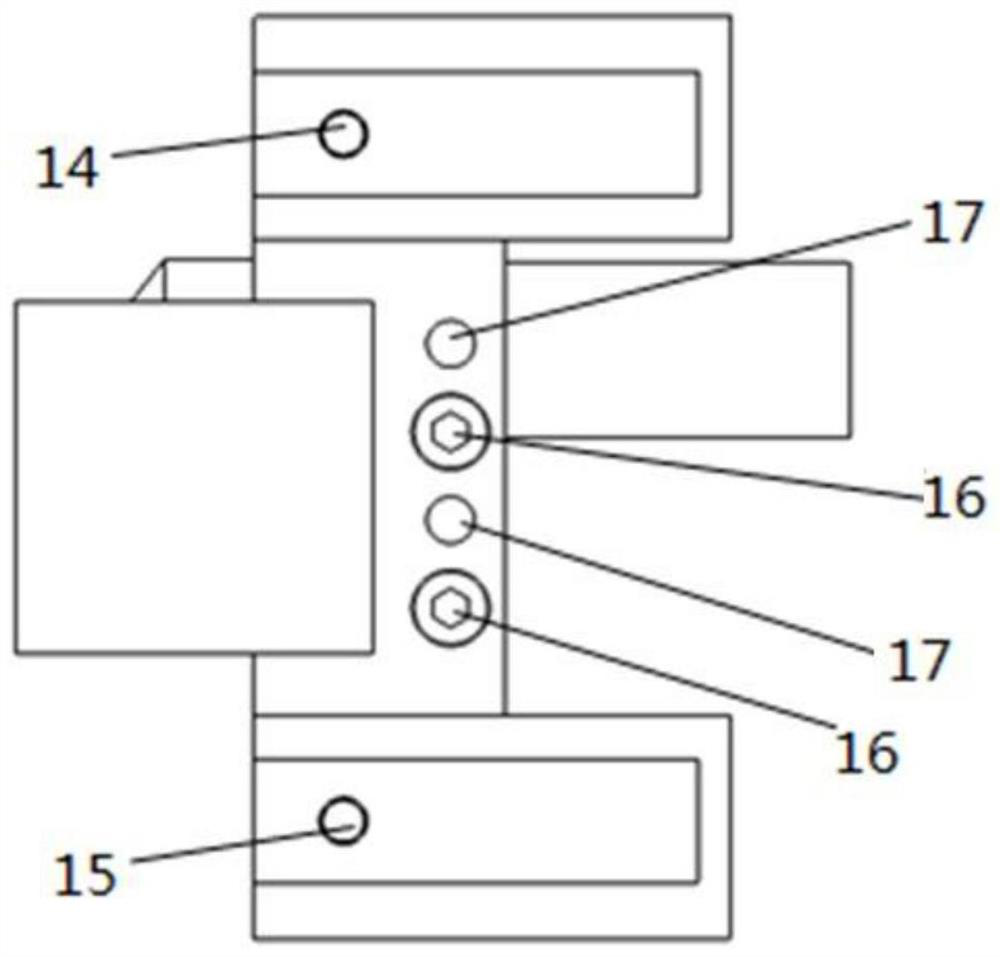

[0025] like Figure 1-3 , The portable pipeline welding stent positioning fixture according to the present embodiment, the body includes a positioning groove 10, Y 20, the main positioning pin 30 and the handle 40 to the fixture body positioning mechanism. The positioning slot 10 includes a positioning groove substrate main body 19, positioned on both surfaces of the grooves are provided with a substrate 19 for controlling the first pipeline stent X / Y to the functional mechanism of the first positioning groove 11, and a control section a pipeline holder X / Y second positioning groove means 13 to function, the first positioning mechanism 11 is provided with a first suction groove magnet 14 of the first suction pipeline stent, the first magnet 14 having a control a first adsorption the Z-function pipeline, the pipeline is provided with a holder holding the second magnet 15 of the second adsorption means within the second positioning groove 13, the second magnet 15 having a suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com