Wastewater solid-liquid separator for chemistry and chemical engineering

A solid-liquid separator, chemical technology, applied in the direction of liquid separation, filtration separation, separation methods, etc., can solve the problems of unable to clean the sediment, unable to clean the filter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

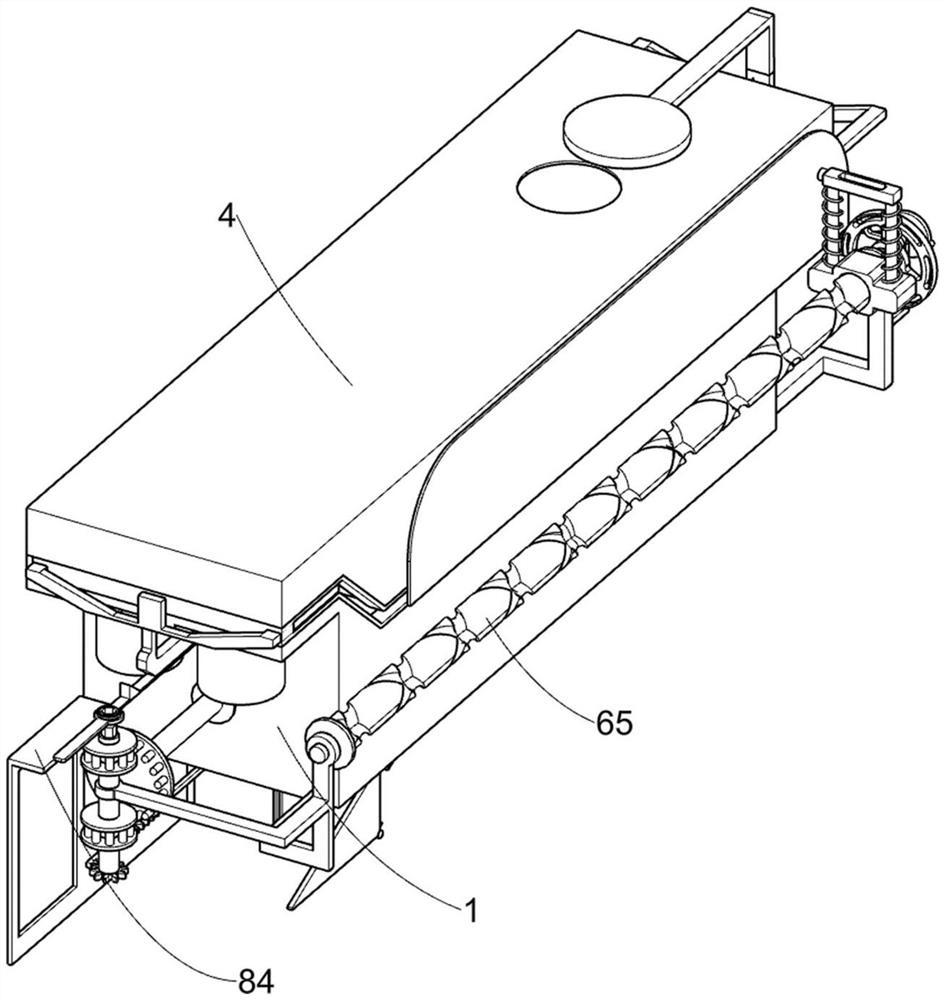

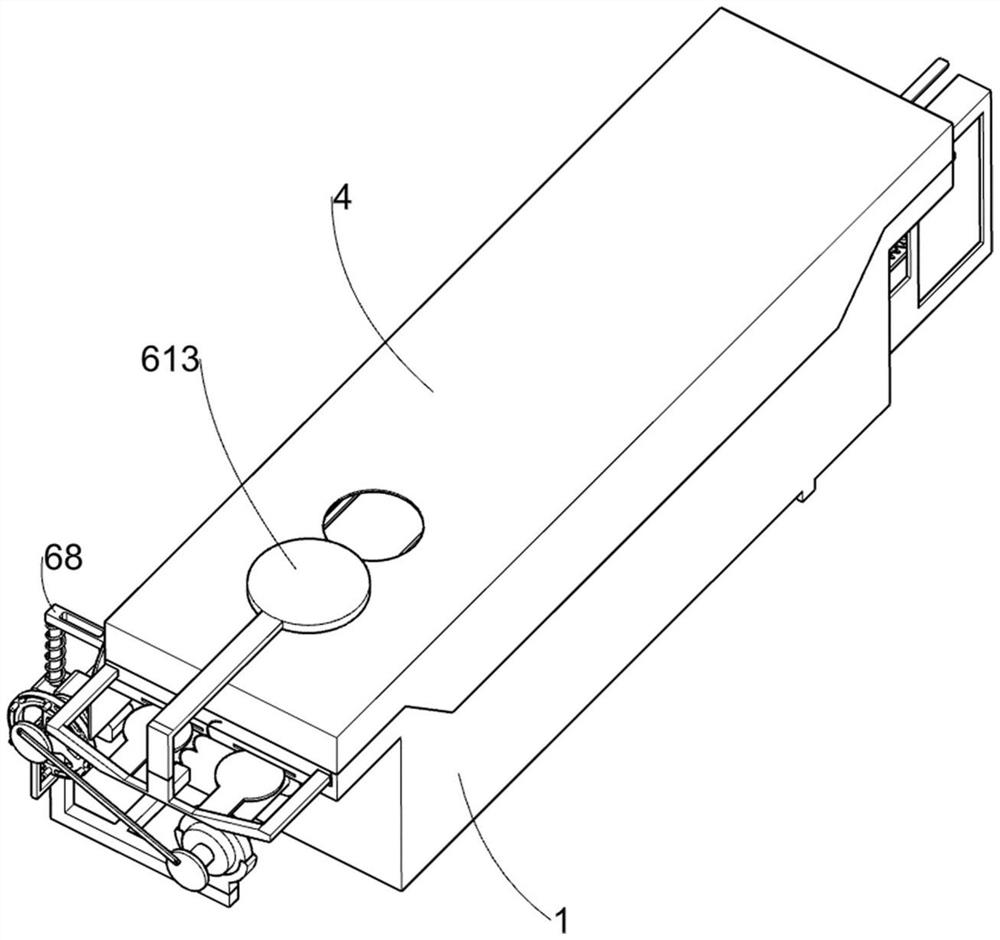

[0031] A kind of waste water solid-liquid separator for chemical industry, such as Figure 1-10 As shown, it includes a waste water collection box 1, a filter box 2, a slide rail plate 3, a sealing cover 4, a rotary stirring mechanism 5, a reciprocating oil scraping and water injection mechanism 6, a rotary push-out mechanism 7 and a toggle mechanism 8 for collecting sewage. A filter box 2 for filtering sediment is fixedly installed at the bottom of the waste water collection box 1, a slide rail plate 3 is positioned on the top surface of the waste water collection box 1, and a seal for sealing the waste water collection box 1 is fixedly installed on the top surface of the slide rail plate 3. The cover 4 and the rotating stirring mechanism 5 are set on the waste water collection tank 1, and the reciprocating oil scraping and water injection mechanism 6 for scraping off the oil stain on the surface of the sewage is arranged on the rotating stirring mechanism 5, and the reciproca...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 11-12 As shown, it also includes a scraping mechanism 9, the scraping mechanism 9 is arranged on the filter box 2, and the scraping mechanism 9 is used to scrape off the sediment remaining inside the special-shaped push plate 75, and the scraping mechanism 9 includes a limit slide bar 91, the second extension spring 92, the second rotating shaft 93, the triangular block 94, the first torsion spring 95, the L-shaped scraper 96, the belt shaft scraper 97 and the second torsion spring 98, the limit slide bar 91 can be lifted connected to the filter box 2 in the same way, the filter box 2 is fixedly connected with a second tension spring 92, and one end of the second tension spring 92 away from the filter box 2 is fixedly connected with the limit slide bar 91, and the limit slide bar 91 The rotation type is connected with a second rotating shaft 93, and a triangular block 94 is welded on the second rotating shaft 93. The triangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com