Fertilizer spreading device for radix paeoniae alba planting

A technology of fertilizer and Radix Paeoniae Alba, which is applied in the field of fertilizer spreading devices for planting Radix Paeoniae Alba, which can solve the problems of uneven fertilizer spreading, different nutrient absorption of crops, and failure to achieve regular and quantitative fertilization effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

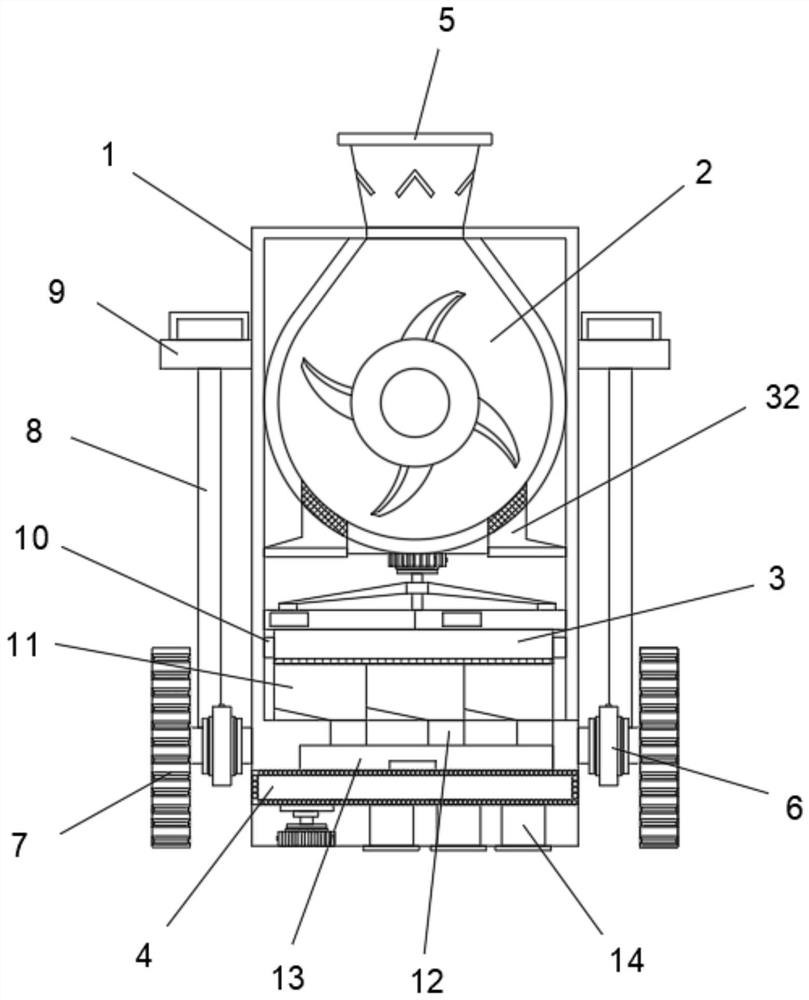

[0031] The specific implementation is as follows:

[0032] 1. First, pour the fertilizer to be spread into the mixing chamber 2 through the feeding port 5. The long-term accumulation of the fertilizer will squeeze the granular fertilizer into pieces, and the stirring blade 31 will be driven by the stirring motor 29 to form a solid mass. The lumps of fertilizer are separated into particles, and the fertilizer is stirred into grains to facilitate the absorption of crops, and it is also convenient for the spreading device to spread. After the stirring is completed, it is transported to the turntable mounting plate of the grain sorting mechanism 3 through the outlet 32 of the mixing chamber. 15 above;

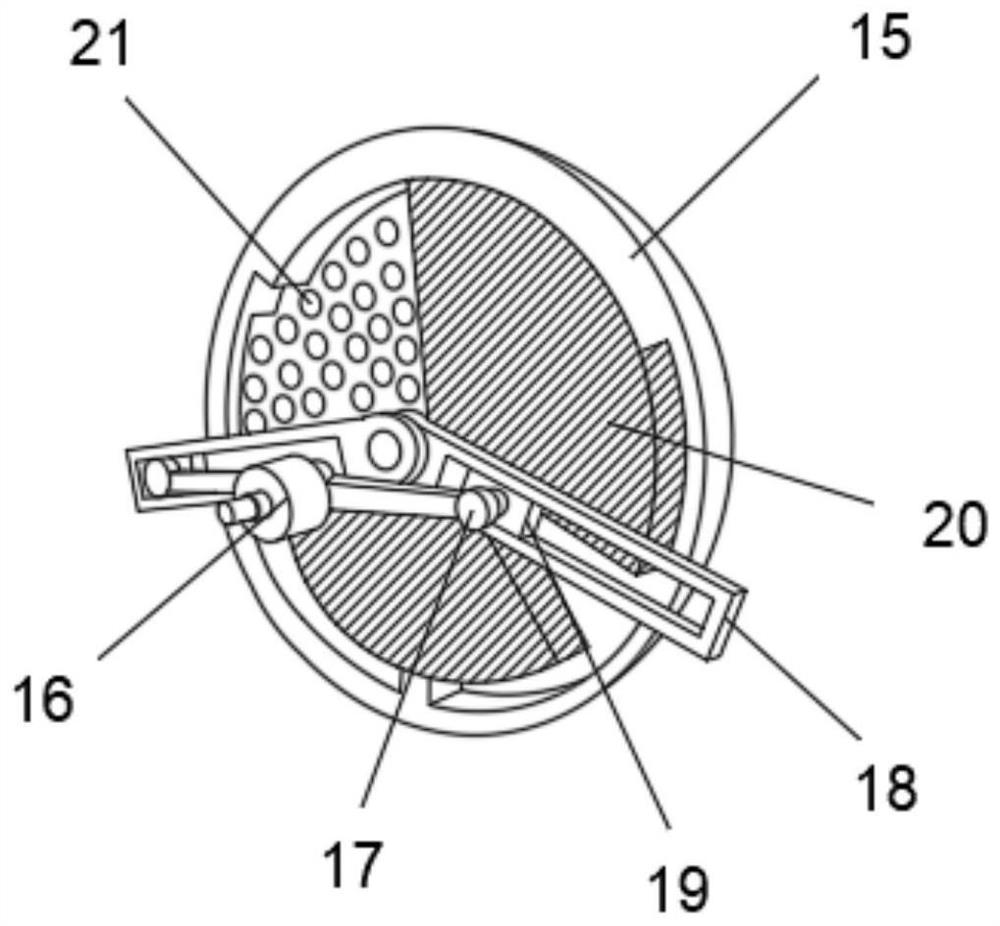

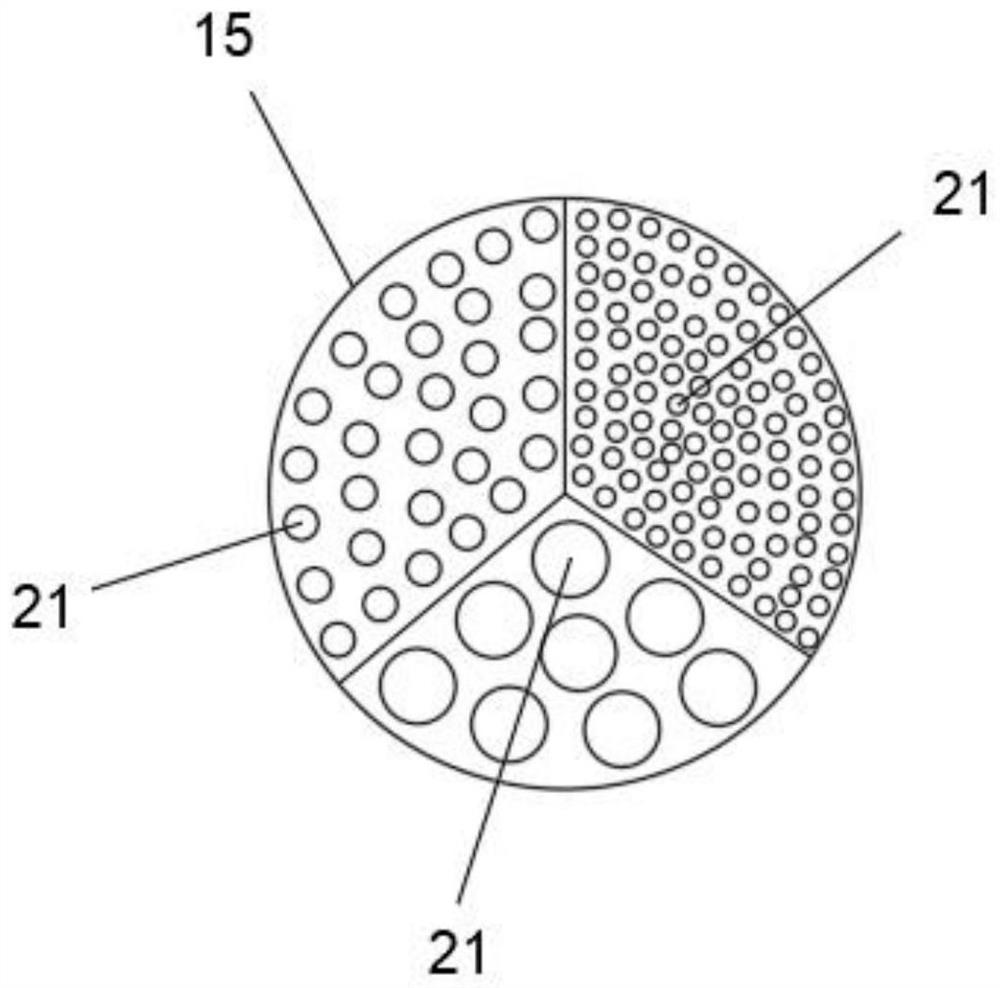

[0033] 2. Then start the first motor to drive the rotation of the rotating shaft 16 to drive the operation of the support arm 17 and the slider 19, and slide the slider 19 in the inner chute of the bracket 18 to drive the fan-shaped turntable 20 in particle sorting The top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com