Air separation type high-stability motor

A high-stability, off-the-shelf technology, used in electromechanical devices, electrical components, wind power generation, etc., can solve problems such as enlargement, generator damage, and continuous working time, to ensure heat dissipation efficiency, improve heat dissipation area, The effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

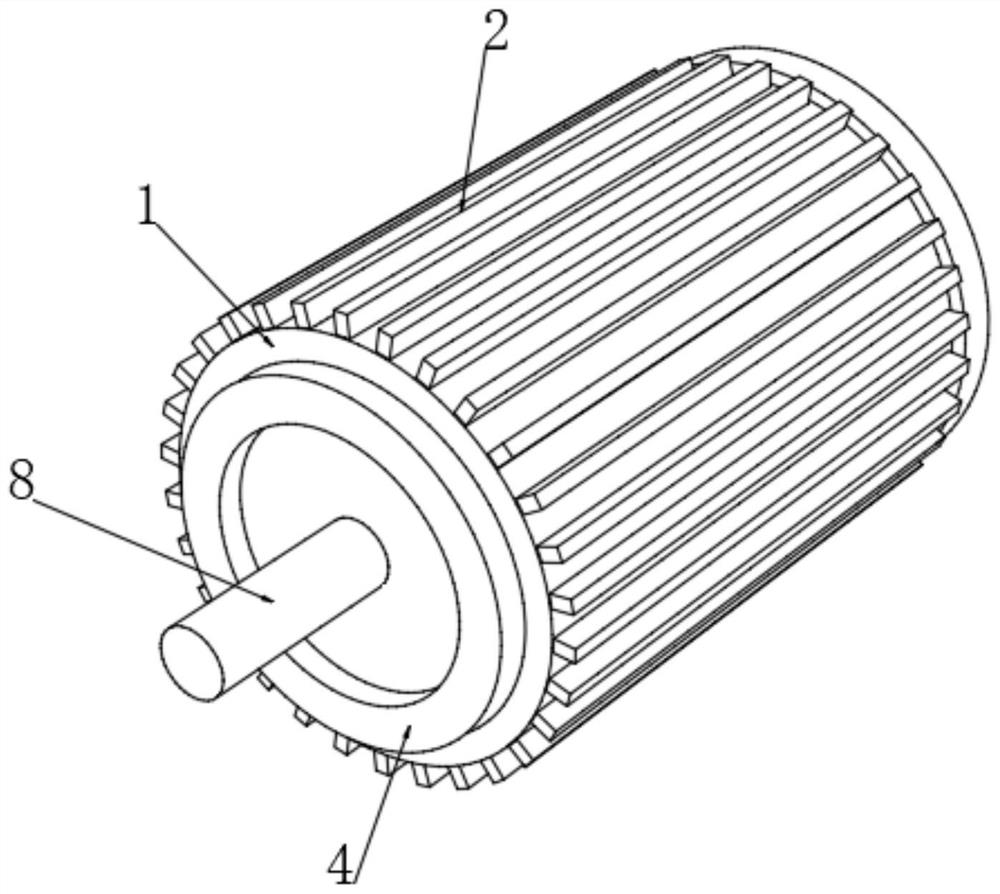

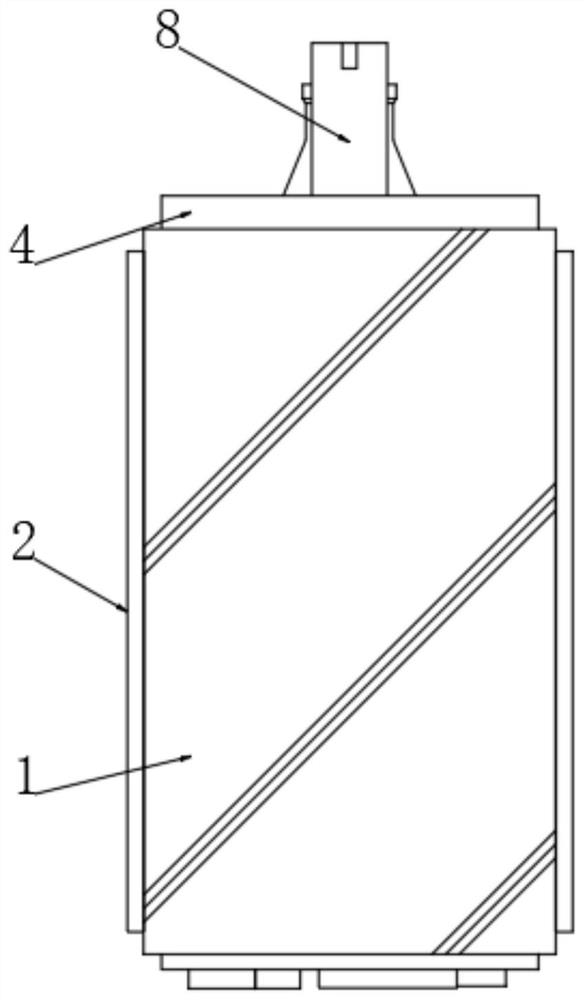

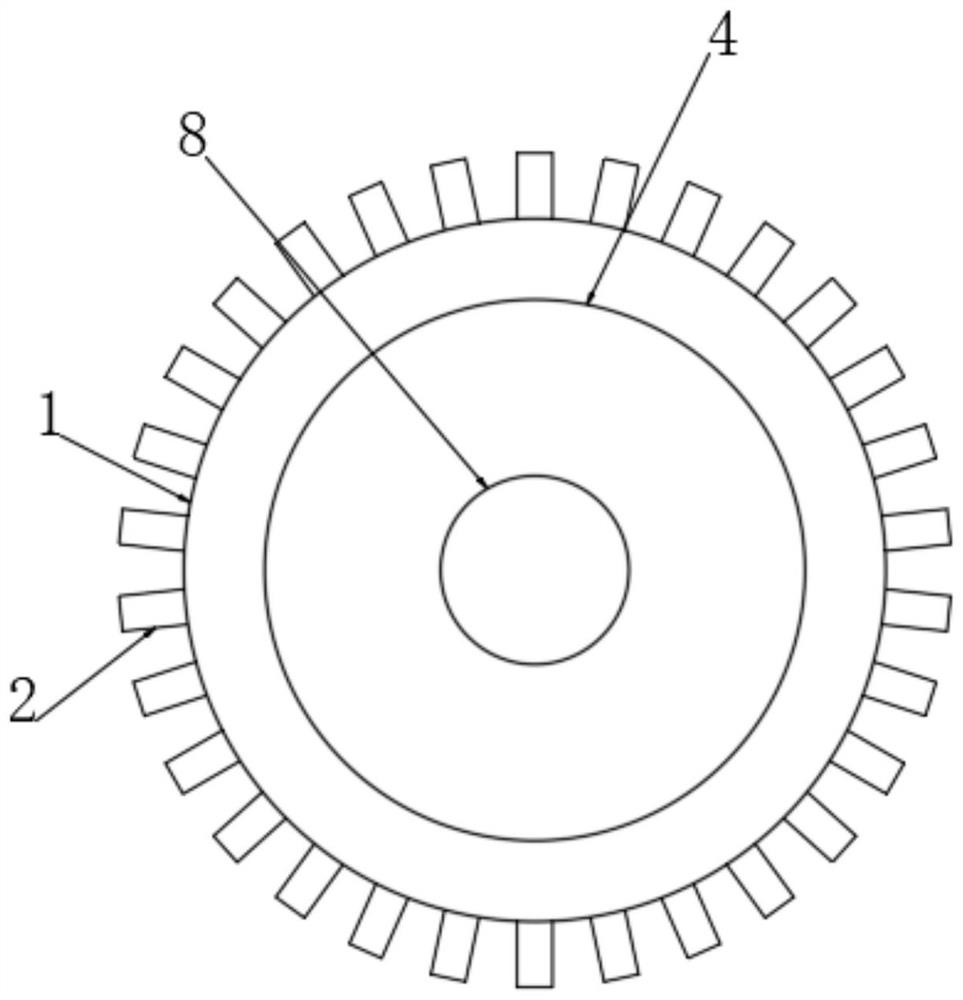

[0041] see Figure 1-3 , a gas-separated high-stability motor, including a motor housing 1, end covers 4 are connected to the upper and lower ends of the motor housing 1, a rotor shaft 8 is connected between the two end covers 4, and the rotor shaft 8 moves through the motor housing 1 The outer end of the motor casing 1 is fixedly connected with a plurality of evenly distributed fan scales 2 .

[0042] see Figure 4 , the fan-type scales 2 include a heat-conducting end 21 fixedly connected to the motor casing 1 and two air-separated scales 22 located at the end of the heat-conducting end 21 away from the motor casing 1, and a heat-conducting silica gel is connected between the two air-separated scales 22 and the heat-conducting end 21 Sheet 3, heat conducting end 21 and air separation scale 22 are all made of hard high thermal conductivity material, and thermal conductive silicone sheet 3 is made of elastic thermal conductivity material, please refer to Figure 5 , when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com