Sodium metal battery and electrochemical device

A sodium metal and battery technology, applied in the field of sodium batteries, can solve the problems of intensifying electrolyte side reactions, consuming active sodium, uneven sodium deposition, etc., achieving the effects of reducing deposition overpotential, ensuring deposition uniformity, and reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of the negative electrode: the negative electrode was prepared by using an aluminum foil with a thickness of 12 um as the negative electrode collector, and the roughness of the negative electrode collector was 0.5 um.

[0059] (2) Preparation of positive electrode: the positive electrode active material NaFeP 2 o 7 , binder polyvinylidene fluoride (PVdF), conductive agent conductive carbon black (Super-P) according to the mass ratio of 96%: 2%: 2% in N-methylpyrrolidone (NMP) solvent mixed uniformly to prepare positive electrode slurry material, use an extrusion coater to coat the surface of the aluminum foil according to the mass requirements per unit area of the positive electrode active material and dry it, and then use a cold press to coat the coated pole piece at a rate of 2.5g / cm 3 The design compaction was carried out by cold pressing to prepare the final positive electrode sheet. The positive electrode materials and coating quality of each emb...

Embodiment 2~3 and comparative example 1~2

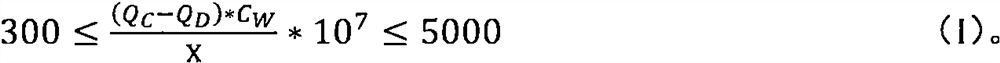

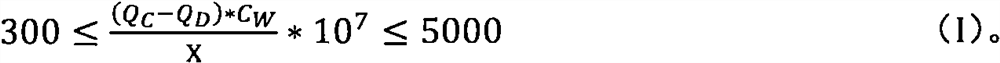

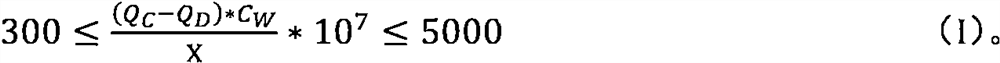

[0065] The difference from Example 1 is that adjusting the first Coulombic efficiency of the battery cell changes the design value of the cell, see Table 1 below for details.

Embodiment 4 and comparative example 3~4

[0067] The difference from Example 1 is that the design value of the cell is changed by adjusting the coating quality of the active material, see Table 1 below for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com