A system, method and application for improving the uniformity of pCVD raw material gas deposition

A technology of raw material gas and uniformity, applied in the direction of manufacturing tools and glass manufacturing equipment, etc., can solve the problems of the effective rod length of the preform, insufficient preheating of the gas raw material, and increase the cost of the optical fiber to ensure deposition uniformity and automation High degree of operation and reduction of cost for rod making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

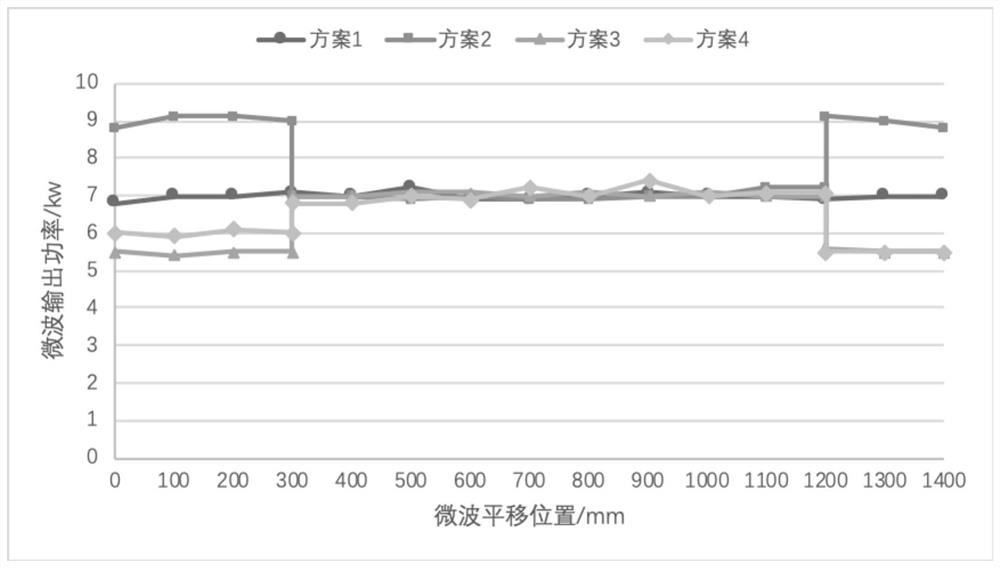

[0087] The PCVD deposition system and method provided in this embodiment are the same as Comparative Example 2, except that in step S4, the actual output power of the microwave generator 4 in the gas end area 20 is set to 5.5kw, and the pump end area 22 The actual output power of the microwave generator 4 is set to 5.0kw. At the same time, the actual output power of the microwave generator 4 in the middle end area 21 is maintained at a preset output power of 7.0 kw.

[0088] During the material gas deposition process, it was observed in this embodiment that there was atomization on the inner surface of the gas end region 20 of the liner 2, which was caused by insufficient actual microwave output power.

[0089] When the system and method are applied to the preparation of optical fiber preform core rods, the relative refractive index and core diameter test results of the obtained core rods can be found in Figure 5 and Image 6 Option 3. see Figure 5 , compared with the sc...

Embodiment 2

[0091] The PCVD deposition system and method provided in this embodiment are the same as Comparative Example 2, except that in step S4, the actual output power of the microwave generator 4 in the gas end area 20 is set to 6.0kw, and the pump end area 22 The actual output power of microwave generator 4 is set to 5.0kw. At the same time, the actual output power of the microwave generator 4 in the middle end area 21 is maintained at a preset output power of 7.0 kw.

[0092] During the raw material gas deposition process, normal deposition was observed on the inner surface of the gas end region 20 of the liner 2 in this embodiment.

[0093] When the system and method are applied to the preparation of optical fiber prefabricated core rods, the relative refractive index and core diameter test results of the obtained core rods can be found in Figure 5 and Image 6 Option 4. see Figure 5 , compared with scheme 1 of comparative example 1, in scheme 4 provided by the present embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com