Test device and test system for electronic components

A technology for testing devices and electronic components, which is applied to electronic circuit testing, measuring devices, measuring device casings, etc., can solve problems such as compression and deformation of the lower end plate of the rack, and achieve the effect of reducing force and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the force balance bracket 5 is connected to the indenter assembly 6 through an intermediate piece (not shown in the figure), and when the indenter assembly 6 crimps the electronic component 3 toward the loading seat 4, the indenter assembly 6 can drive the intermediate piece to connect the force balance One end of the bracket 5 moves away from the loading seat 4 , so that the force balance bracket 5 can move away from the loading base 4 and apply a force on the loading base 4 away from the lower end plate 2 . The above-mentioned middle piece acts as a lever, and the pressure head assembly 6 drives one end of the middle piece to move toward the direction of the loading seat 4, while the other end of the middle piece moves in the opposite direction, thereby driving the force balance bracket 5 to move away from the loading The direction of the seat 4 moves and exerts a force on the loading seat 4 away from the lower end plate 2 .

Embodiment 2

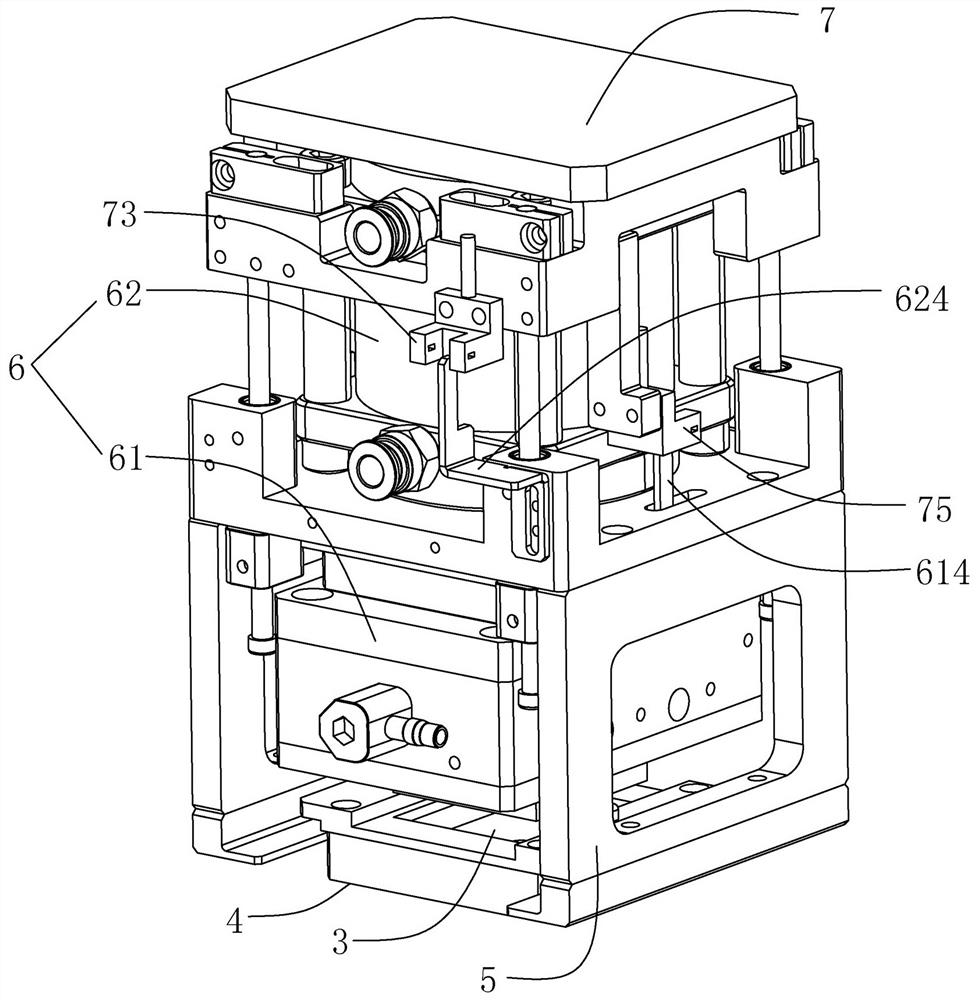

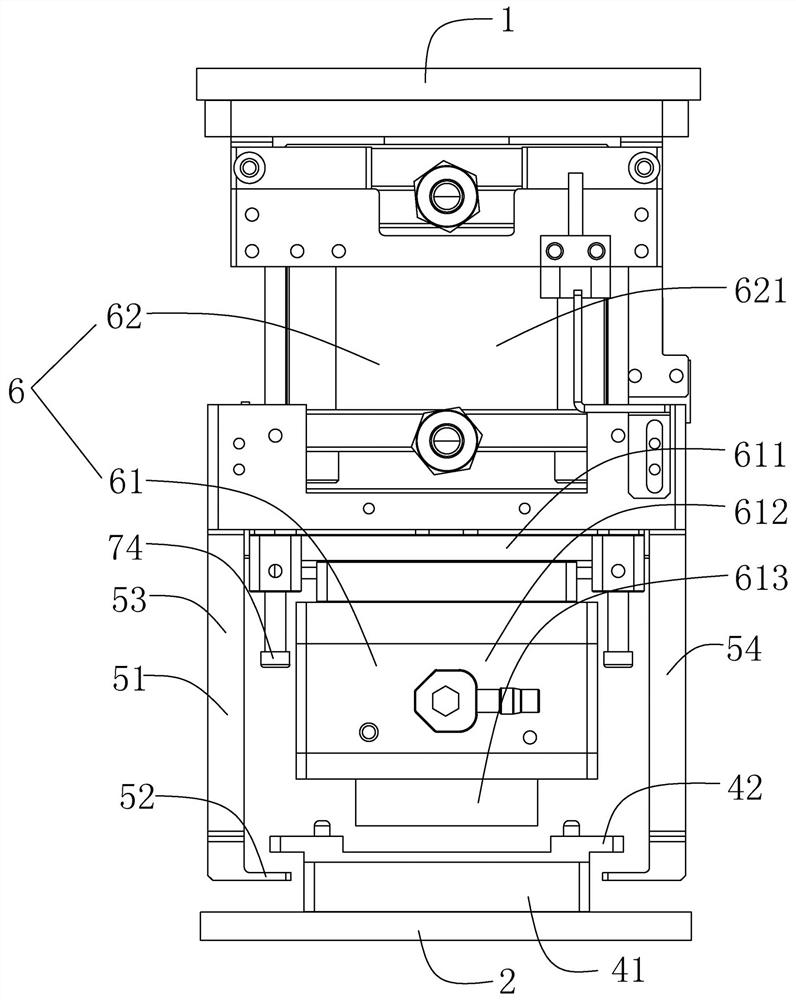

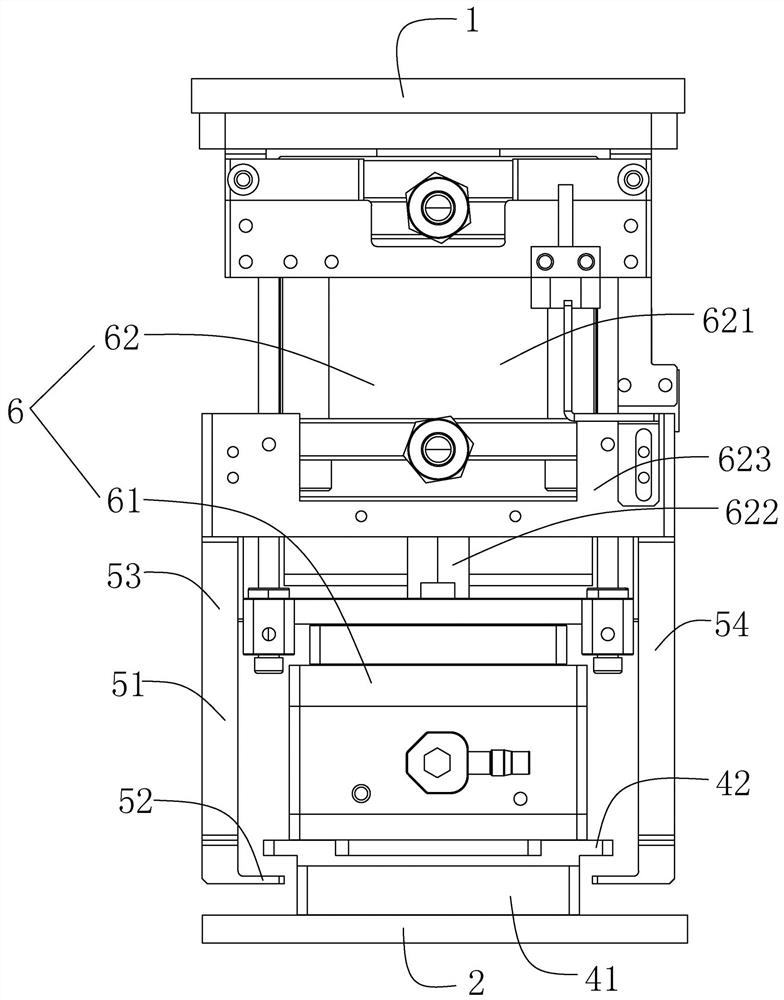

[0042] Embodiment two, such as Figure 1-Figure 4 As shown, the ram assembly 6 includes a power assembly 62 and a crimping assembly 61, the crimping assembly 61 is movably connected to the power assembly 62, and the power assembly 62 can drive the crimping assembly 61 to move toward or away from the carrier 4 to press connected to or away from the electronic component 3, the force balance bracket 5 is fixedly connected to the power assembly 62, when the crimping assembly 61 abuts against the electronic component 3, the crimping assembly 61 can reversely push the power assembly 62 to move away from the lower end plate 2, And the force balance bracket 5 can hook the loading seat 4 and apply a force to the loading base 4 away from the lower end plate 2 .

[0043] Specifically, such as Figure 5 As shown, the power assembly 62 includes a driving cylinder. The driving cylinder includes a cylinder body 621 and a piston 622. One end of the piston 622 is movably connected to the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com