Airborne drilling and splitting combined machine

A combined machine and mounting frame technology, which is applied to drilling equipment and methods, discharge machinery, earthwork drilling and mining, etc. It can solve the problem of stone materials with a large surface inclination that cannot be mined, the self-heaviness of drilling rigs and hydraulic splitting machines, and manual handling. Inconvenience and other problems, to achieve the effect of easy purchase and maintenance, controllable turning angle and mature structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

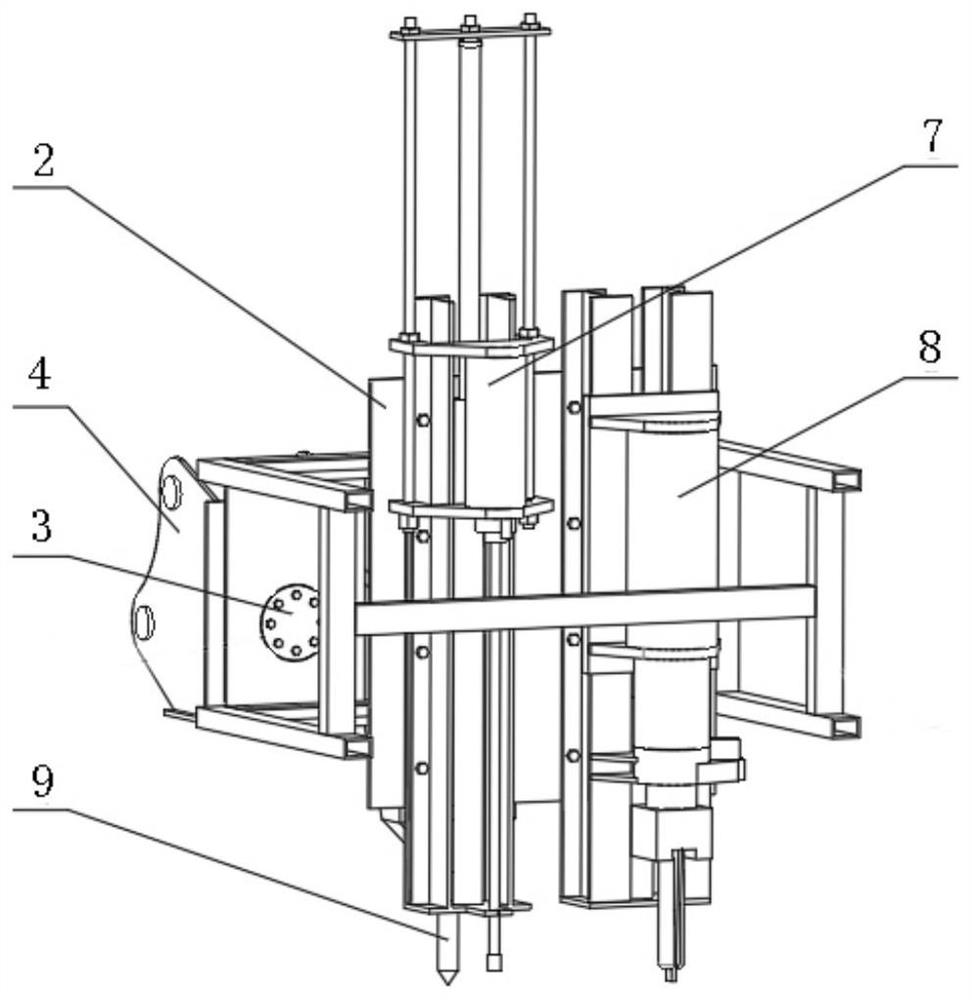

Embodiment 1

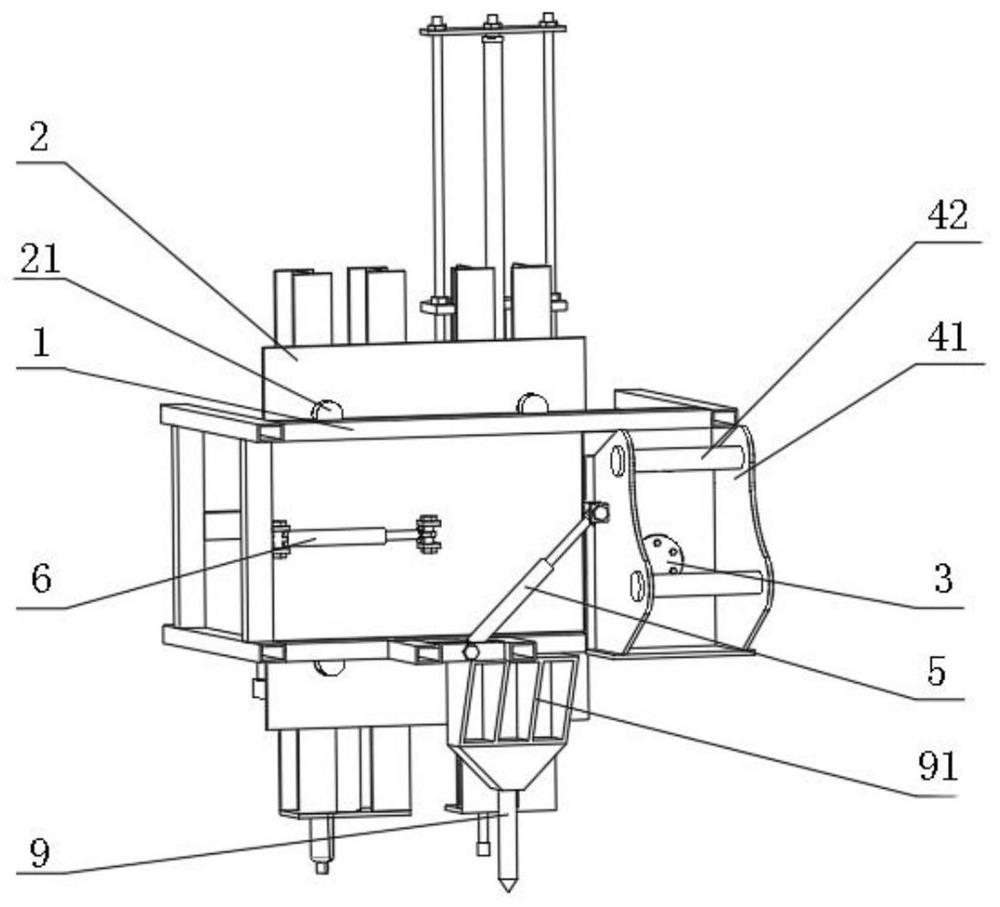

[0034] In this embodiment, an airborne drilling and splitting combination machine is designed, which includes a mounting frame 1 and a transposition plate 2. The mounting frame 1 is provided with a slewing support 3, and the slewing support 3 is a bearing. The slewing support 3 is connected with hanging lugs. 4. The slewing ring 3 is made of bearings, which have a mature structure and are easy to purchase and maintain. The inner ring and outer ring of the bearing are relatively fixed on the mounting frame 1 and the mounting lug 4 respectively, and the mounting lug 4 is formed by a square grooved lug plate 41 and the trunnion 42 fixed on the groove wall of the lug plate 41, which can make the whole equipment more convenient to hang on other movable construction machinery such as excavators, and the slewing bearing 3 is connected to the groove bottom of the lug plate 41 , the hanging lug 4 is used to hang on movable construction machinery such as excavators, and a rotation degree...

Embodiment 2

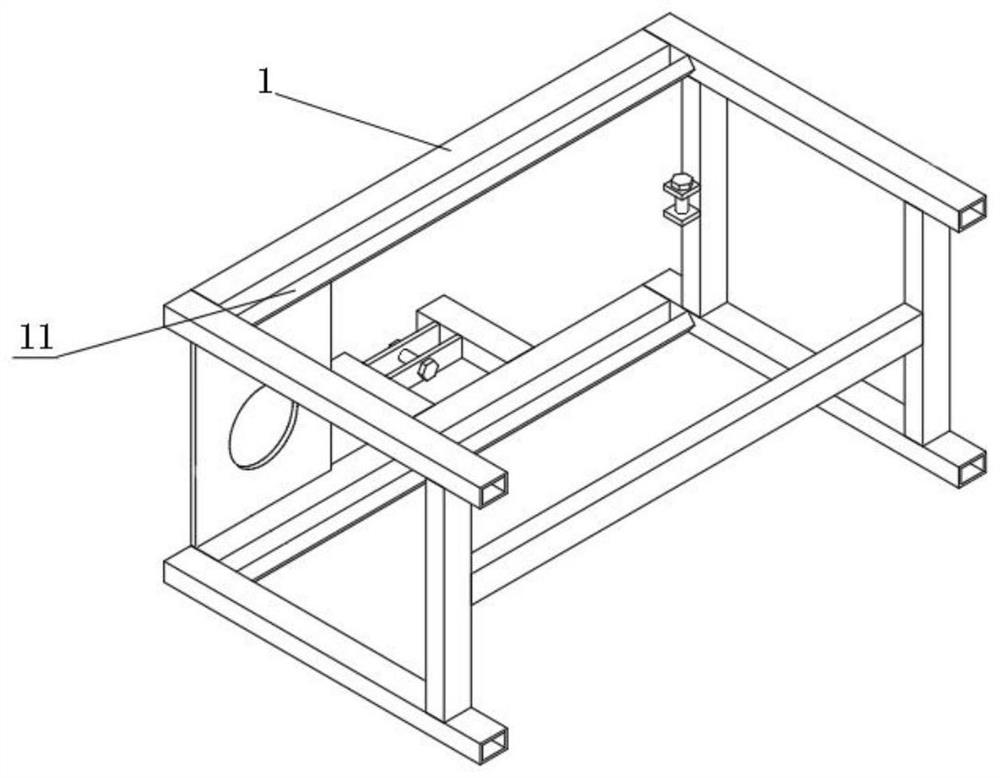

[0037] In this embodiment, an airborne drilling and splitting combination machine is designed, which includes a mounting frame 1 and a transposition plate 2. The mounting frame 1 is spliced by rod-shaped profiles, and supporting guardrails are provided on both sides of the mounting frame 1. The installation frame 1 is provided with a slewing bearing 3, and the slewing bearing 3 is connected with a hanging lug 4. The slewing bearing 3 is preferably a single-row cross roller type, with a mature structure, easy to purchase and maintain, the inner race of the slewing bearing 3 and the hanging The ear 4 is connected by bolts, the outer race is connected with the mounting frame 1 by bolts, the mounting frame 1 can rotate around the slewing support 3, and the hanging lug 4 is fixed in the groove of the hanging lug plate 41 by a square groove-shaped lug plate 41 The hanging trunnion 42 of the wall is composed of two hanging trunnions 42, and the two hanging trunnions 42 are parallel ...

Embodiment 3

[0039] In this embodiment, an airborne drilling and splitting combination machine is designed, which includes a mounting frame 1 and a transposition plate 2. The mounting frame 1 is welded by tubular profiles, and the mounting frame 1 is provided with a slewing support 3, which 3 is connected with hanging lug 4, the slewing bearing 3 is preferably a single-row cross roller type, with a mature structure, easy to purchase and maintain, the outer race of the slewing bearing 3 and the lug 4 are connected by bolts, and the inner race and installation The frame 1 is connected by bolts, and the mounting frame 1 can rotate around the slewing bearing 3. The hanging lug 4 is composed of a square groove-shaped hanging lug plate 41 and a hanging trunnion 42 fixed on the groove wall of the hanging lug plate 41. The hanging trunnion 42 is provided with two, two hanging trunnions 42 are parallel to each other, and the distance from the bottom of the groove of the hanging lug plate 41 is differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com