Galla chinensis-derived plant antibacterial dye and extraction method thereof

A plant antibacterial and extraction method technology, applied in the field of Galla gall dyes, can solve the problems of short antibacterial properties, poor heat resistance, loss of antibacterial properties, etc., and achieve the effects of increasing stability, strengthening antibacterial cycle, and enhancing antibacterial types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

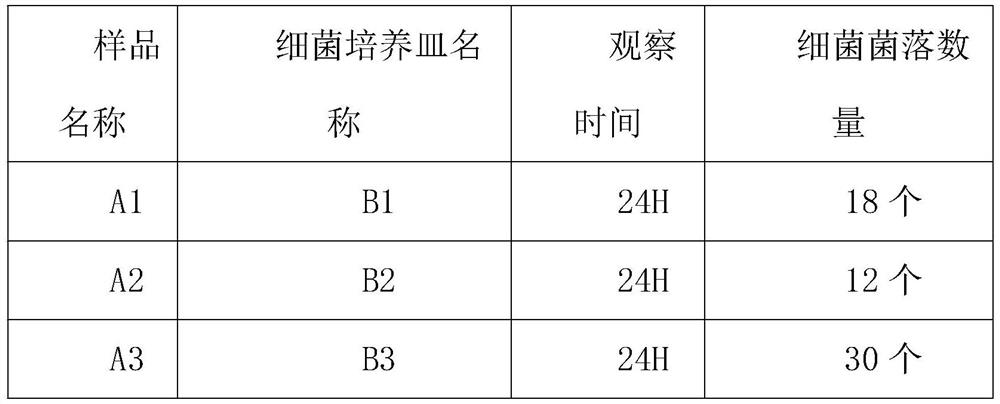

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of plant antibacterial dye derived from gallnut, comprising the following distribution ratio composition: 50 parts of gallnut raw material, 5-8 parts of chitin, 5-10 parts of benzophenone and 2-5 parts of dispersant.

[0021] A plant antibacterial dye derived from Galla japonica and an extraction method thereof, comprising the following steps:

[0022] S1: Clean and dry the gall raw material, and then place it in a traditional Chinese medicine pulverizer to pulverize it into powder;

[0023] S2: The powder is then placed in the extraction container, and 50 parts of ethanol and 70 parts of water are added, and mixed by mixing equipment, then heated to 50°C, and the gall dye is taken out and sent to the heat preservation device for heat preservation. The temperature is 50°C, then the filtered residue is put into the residue extruder for solid-liquid separation, the separated liquid is mixed with the original liquid, the mixing time of the mixing equip...

Embodiment 2

[0027] Embodiment 2: a kind of plant antibacterial dye derived from gallnut, comprising the following distribution ratio composition: 50 parts of gallnut raw material, 5-8 parts of chitin, 5-10 parts of benzophenone and 2-5 parts of dispersant.

[0028] A plant antibacterial dye derived from Galla japonica and an extraction method thereof, comprising the following steps:

[0029] S1: Clean and dry the gall raw material, and then place it in a traditional Chinese medicine pulverizer to pulverize it into powder;

[0030] S2: The powder is then placed in the extraction container, and 70 parts of ethanol and 80 parts of water are added, and mixed by mixing equipment, then heated to 55°C, and the gall dye is taken out and sent to the heat preservation device for heat preservation. The temperature is 55°C, then the filtered residue is put into the residue extruder for solid-liquid separation, the separated liquid is mixed with the original liquid, the mixing time of the mixing equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com