Application of three-component reaction catalyzed by biomass-supported copper in the preparation of fluorine-containing drugs

A biomass, copper catalysis technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc. Efficient recycling ability, the effect of promoting industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

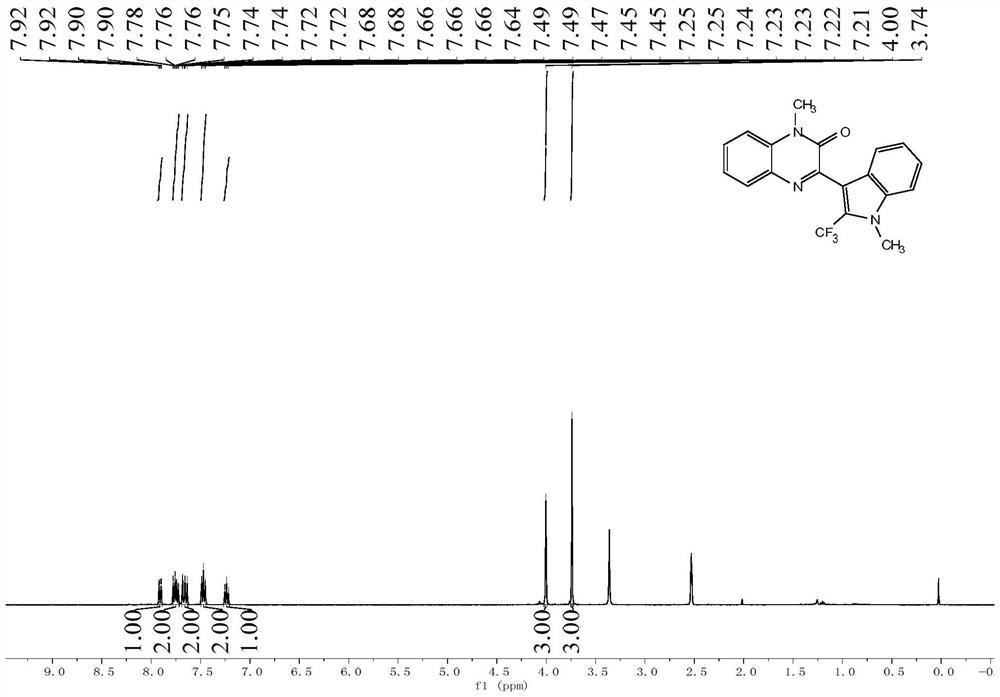

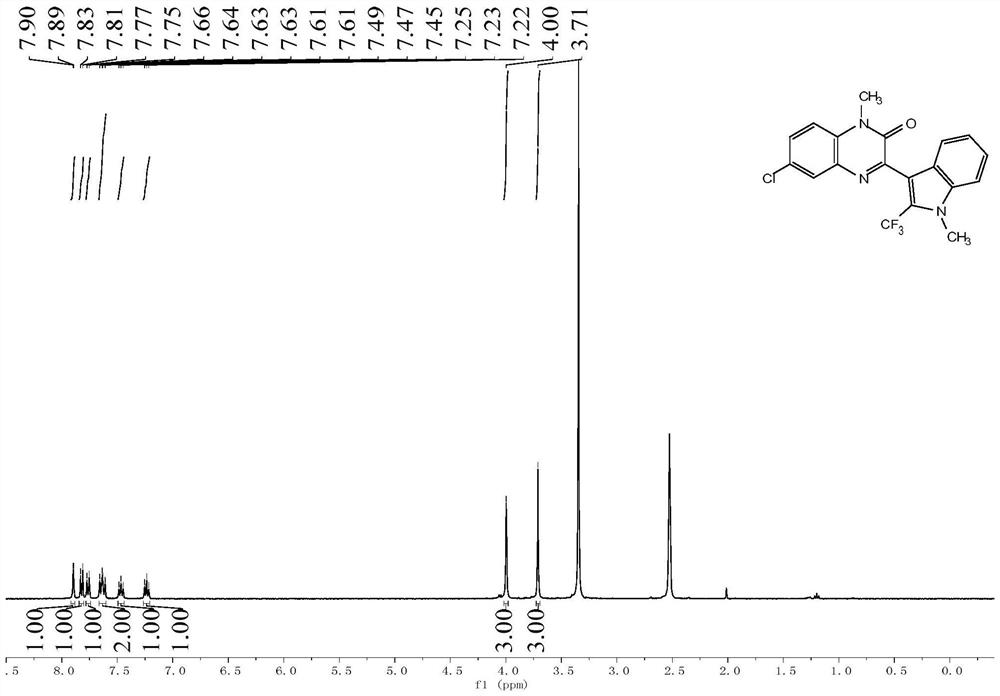

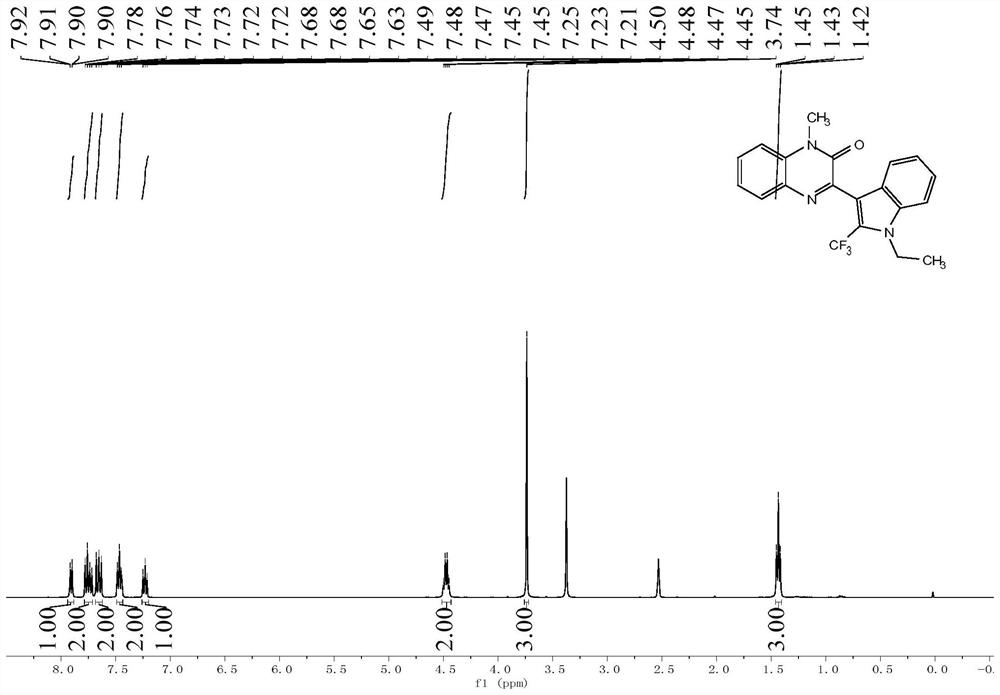

Examples

preparation example Construction

[0045] Preparation of Chitosan-supported Copper Catalyst

[0046] In a 100 mL round bottom flask, dissolve anhydrous copper acetate in H 2 O middle. Chitosan was then added to the solution to obtain a suspension which was stirred at 40 °C for 8 h. After the solution was cooled to room temperature, the H was slowly removed by suction filtration under reduced pressure. 2 O, the filter cake was washed three times with ethanol and water to give a light blue solid. The obtained light blue solid was dried under vacuum at 60 °C for 12 hours; different Cu(OAc) 2 Loaded chitosan-supported copper catalyst. The chitosan supported copper catalyst was named Cu(OAc) 2 @CS. Different Cu(OAc) 2Catalysts with loads were prepared according to the above method, and catalysts with loads of 10, 15, 20, and 30 mol% were prepared respectively, named as Cu(OAc) 2 @CS-10, Cu(OAc) 2 @CS-15, Cu(OAc) 2 @CS-20, Cu(OAc) 2 @CS-30.

Embodiment 1

[0048] The preparation of N-methylquinoxalinone (R in structural formula (II) 1 is methyl, R 2 for H)

[0049] In a 100mL round bottom flask, add 2-hydroxyquinoxalinone (12mmol, 1.75g), potassium hydroxide (42mmol, 2.36g), 15mL N,N-dimethylformamide (DMF), under ice bath After stirring, a DMF solution of iodomethane (14.4 mmol, 2 g) was added dropwise to the round bottom flask. After the dropwise addition, the reaction was continued at room temperature for 6 hours, and the reaction was detected by TLC. After the reaction was completed, the reaction solution was washed with saturated ammonium chloride solution, extracted with ethyl acetate, and the organic phase was washed with brine, the organic phase was separated, dried, spin-dried, and extracted with petroleum ether and ethyl acetate (10:1 ) ratio is that the eluent is purified through the column, and N-methylquinoxalinone is obtained after drying.

[0050] The preparation of N-methylindole (R in structural formula (III)...

Embodiment 2

[0057] Effect of Different Catalysts

[0058] Chitosan supported copper acetate Cu(OAc) 2 @CS-10, Cu(OAc) 2 @CS-20, Cu(OAc) 2 @CS-30 replaces Cu(OAc) 2 @CS-15, the yields of the prepared target products were 76%, 87%, and 81%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com