Heavy oil well sand prevention effect evaluation test device and evaluation test method

A technology for testing devices and oil wells, applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the problems of not reflecting the process of forming sand bridges, poor reproducibility of experimental results, deviation of experimental results, etc., to achieve the experimental period Short, low manufacturing cost, and the effect of reducing experimental bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

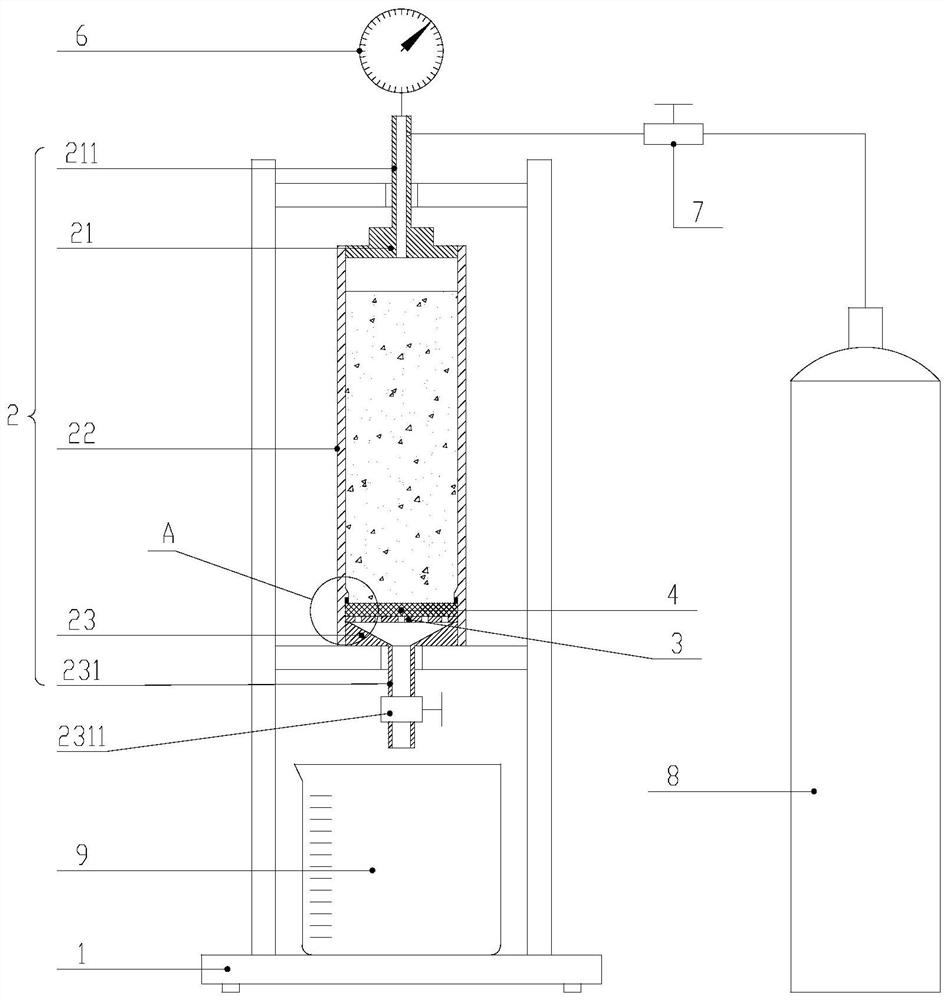

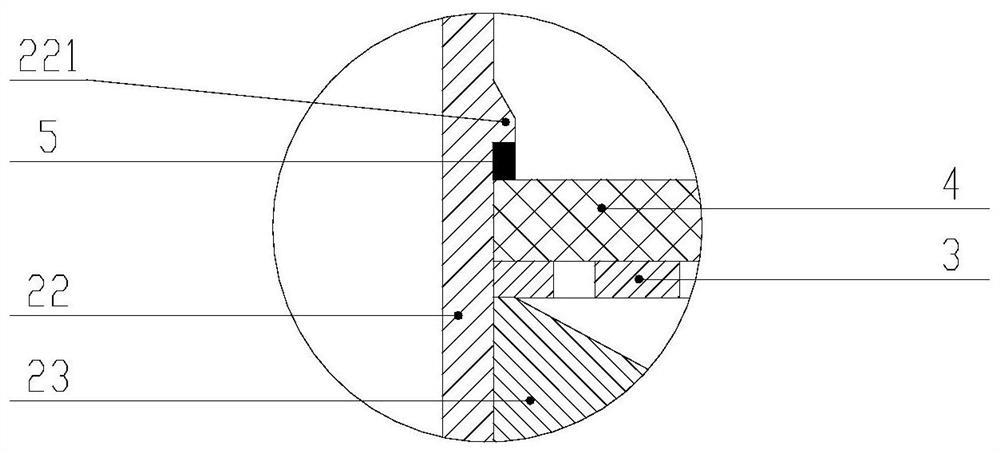

[0033] Such as figure 1 , figure 2 and image 3 As shown, this embodiment provides a sand control effect evaluation test device for heavy oil wells, including a vertically arranged test cylinder 2 with a chamber, the upper end of the test cylinder 2 is connected with a gas source capable of delivering gas to the chamber of the test cylinder 2 8. A support plate 3 with a plurality of through holes is horizontally provided adjacent to the bottom of the chamber, a certain gap is left between the support plate 3 and the bottom surface of the chamber, and a sieve filter sample 4 is provided above the support plate 3. The chamber and above the screen filter sample 4 are filled with uniformly mixed simulated mortar. The lower end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com