High-sensitivity temperature sensor based on hollow-core optical fiber and manufacturing method thereof

A technology of temperature sensor and hollow-core optical fiber, which is applied in the field of high-sensitivity temperature sensor and its manufacture, can solve the problems of corrosion, error, and difficulty in obtaining sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

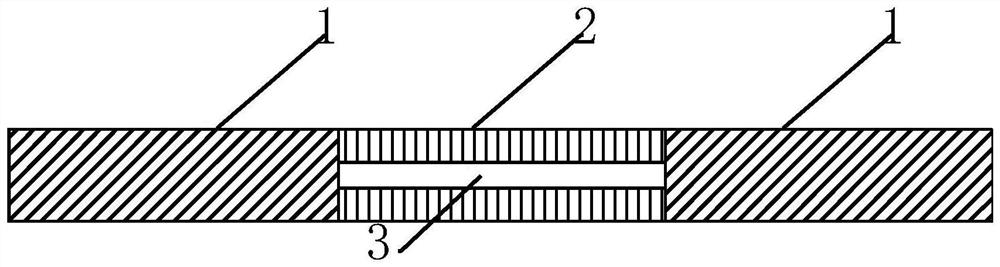

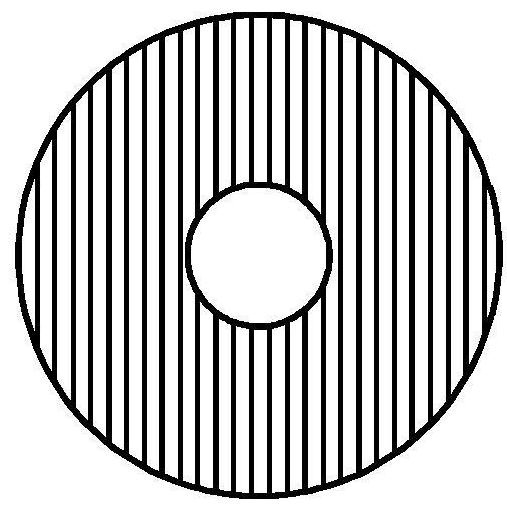

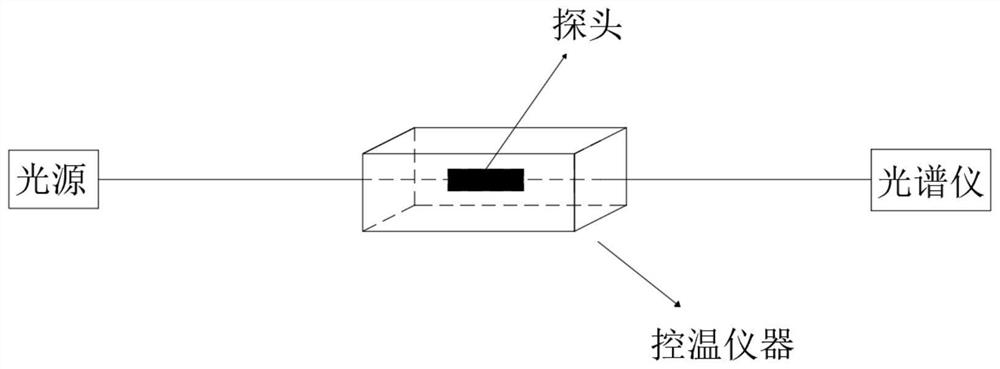

[0027] In the high-sensitivity temperature sensor based on the hollow-core optical fiber of the present invention, the two ends of the hollow-core optical fiber are welded between ordinary single-mode optical fibers, wherein the hollow-core optical fiber is filled with a liquid with a specific refractive index. The single-mode optical fiber at both ends of the sensor probe is used as the input and output components of the optical signal, and is respectively connected to the broadband light source and the spectrometer. The hollow-core optical fiber in the middle is placed horizontally in the temperature area to be measured as the probe of the temperature sensor, and then the temperature is measured. The light incident on the device from the light source will interfere when it passes through the hollow-core fiber, resulting in a loss peak at a specific wavelength. When the am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com