Foam scrubbing agent as well as preparation method and application thereof

A technology of foam discharge agent and solvent, applied in chemical instruments and methods, drilling composition and other directions, can solve problems such as hindering the application of foam drainage and gas recovery process, reducing foaming and foam stabilizing ability, and rarely reporting nanomaterials, etc. , to improve the liquid-carrying capacity, enhance the stability, and reduce the surface interfacial tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

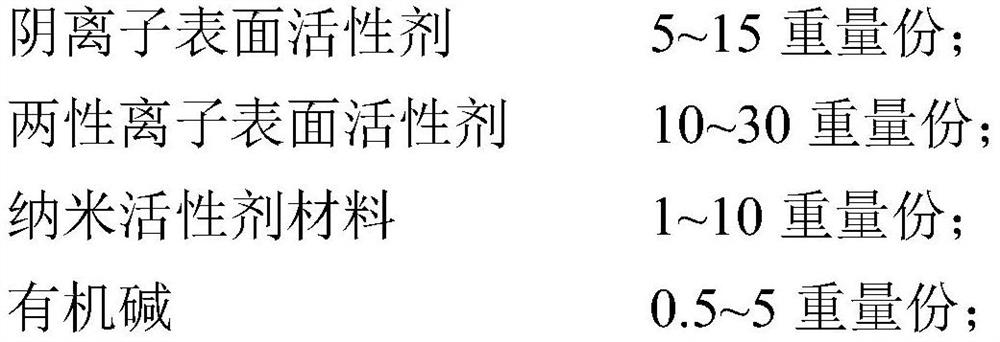

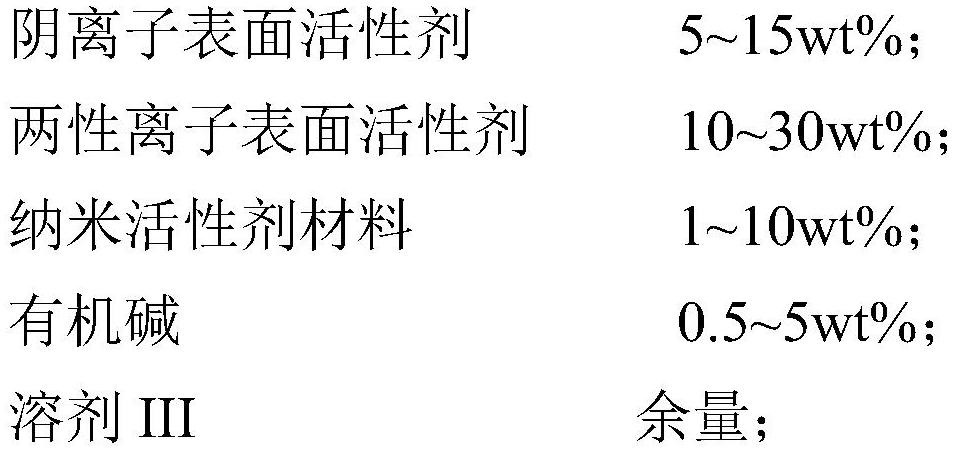

Method used

Image

Examples

Embodiment 1

[0107] The preparation of embodiment 1 foam discharge agent

[0108] Weigh anionic surfactant (specifically sodium lauryl sulfate) and zwitterionic surfactant (specifically erucamide propyl sulfobetaine) into water, stir with mechanical stirring at 250rpm at normal temperature (20°C) After 10 minutes, the foam discharge agent base liquid was obtained. Weigh the nano-active agent material and add it to the foam discharge agent base liquid at 40°C, stir with a mechanical stirrer at 250rpm for 10 minutes, test the pH value of the foam discharge agent, weigh the organic base (diethanolamine), and add the organic base while stirring to adjust the foam. When the pH of the discharge agent reaches 6, the foam discharge agent is obtained. In the obtained foam discharge agent, the content of the anionic surfactant is 10wt%, the content of the zwitterionic surfactant is 20wt%, the content of the nano-active agent material is 5wt%, and the content of the organic base is 1wt%. . Gained f...

Embodiment 2~3

[0117] The preparation of embodiment 2~3 foam discharge agent

[0118] The difference between the preparation method of Examples 2-3 and Example 1 is only as shown in Table 3 below

[0119] Table 3 The difference between embodiment 2~3 and embodiment 1

[0120]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com