A kind of anti-volatile environment-friendly uv printing machine

An environmentally friendly, anti-volatile technology, used in printing presses, rotary printing presses, general parts of printing machinery, etc., can solve problems such as increasing resource consumption, affecting workers' health, and ink volatilization, reducing waste of resources and using safe. Convenience, the effect of reducing spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

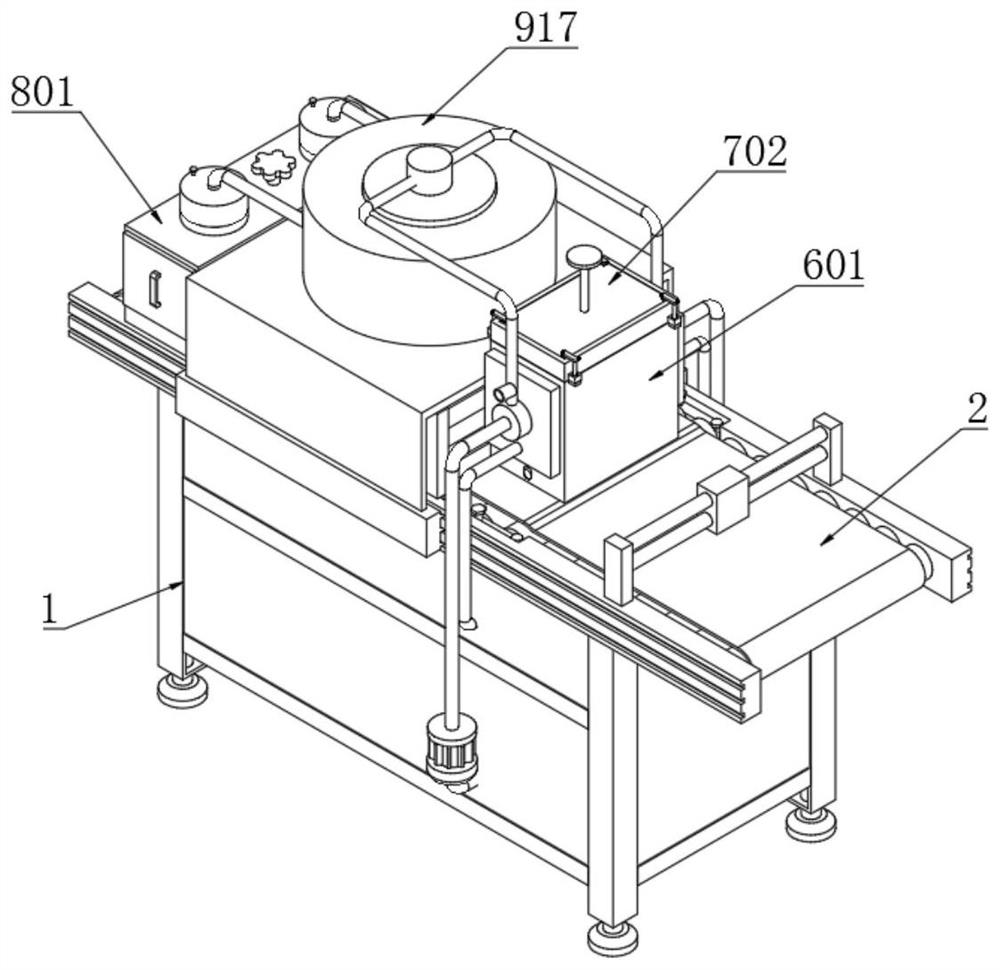

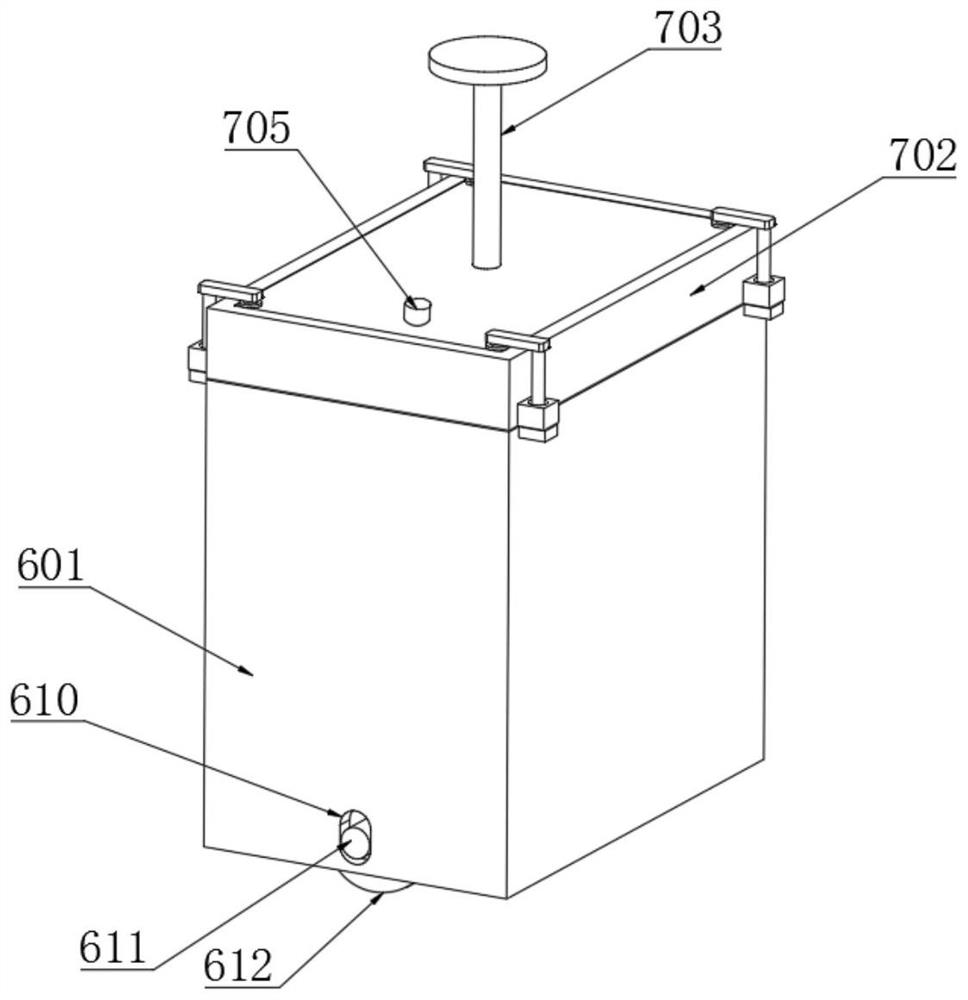

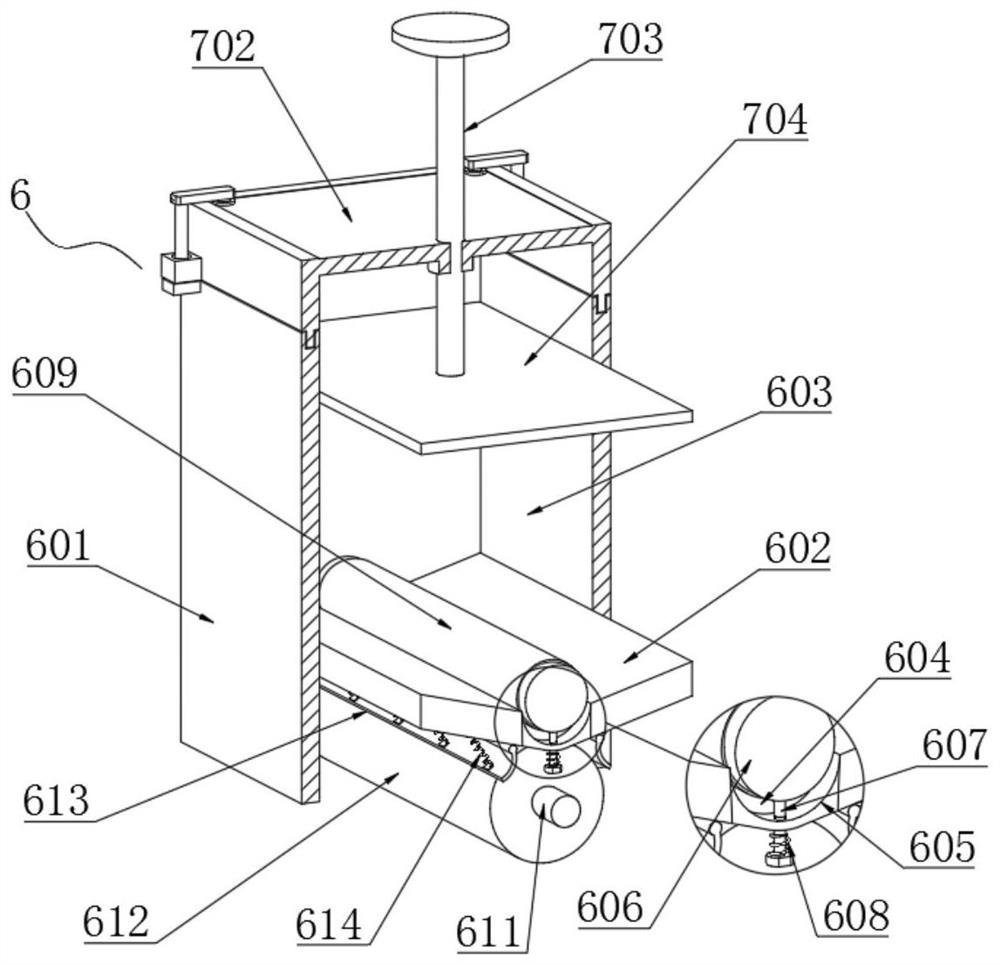

[0037] Example: as Figure 1-10 As shown in the figure, the present invention provides a technical solution, an environmentally friendly UV printing machine with anti-volatile A vertical plate 3 is fixedly connected, a mounting rod 4 is welded at an equal distance between the two vertical plates 3, a mounting seat 5 is sleeved on the outside of the mounting rod 4, and one end of the mounting seat 5 is provided with a printing and leak-proof mechanism 6. The mechanism 6 includes an ink cartridge 601, a partition 602, a storage chamber 603, an ink outlet 604, a baffle 605, a shaft seat 606, a vertical rod 607, a tension spring 608, an ink roller 609, a groove 610, a horizontal rod 611, a printing Roller 612, arc plate 613, support spring 614, expansion groove 615, lift plate 616, screw 617, limit rod 618 and support roller 619;

[0038] One end of the mounting base 5 is provided with an ink cartridge 601, a partition 602 is welded at the bottom of the inner wall of the ink cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com