Real-time cutter detection device for machining center and detection method thereof

A real-time detection and processing center technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult tool wear degree detection, part size deviation, processing efficiency, etc., to ensure quality and improve Product accuracy, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

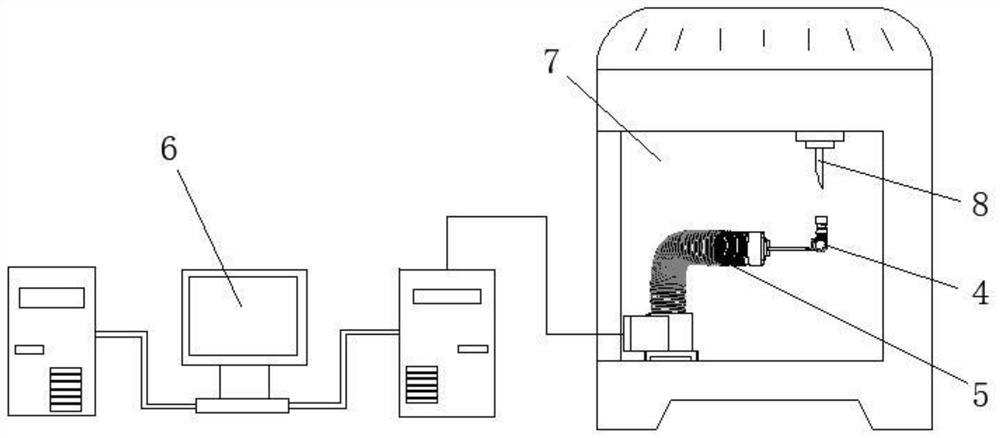

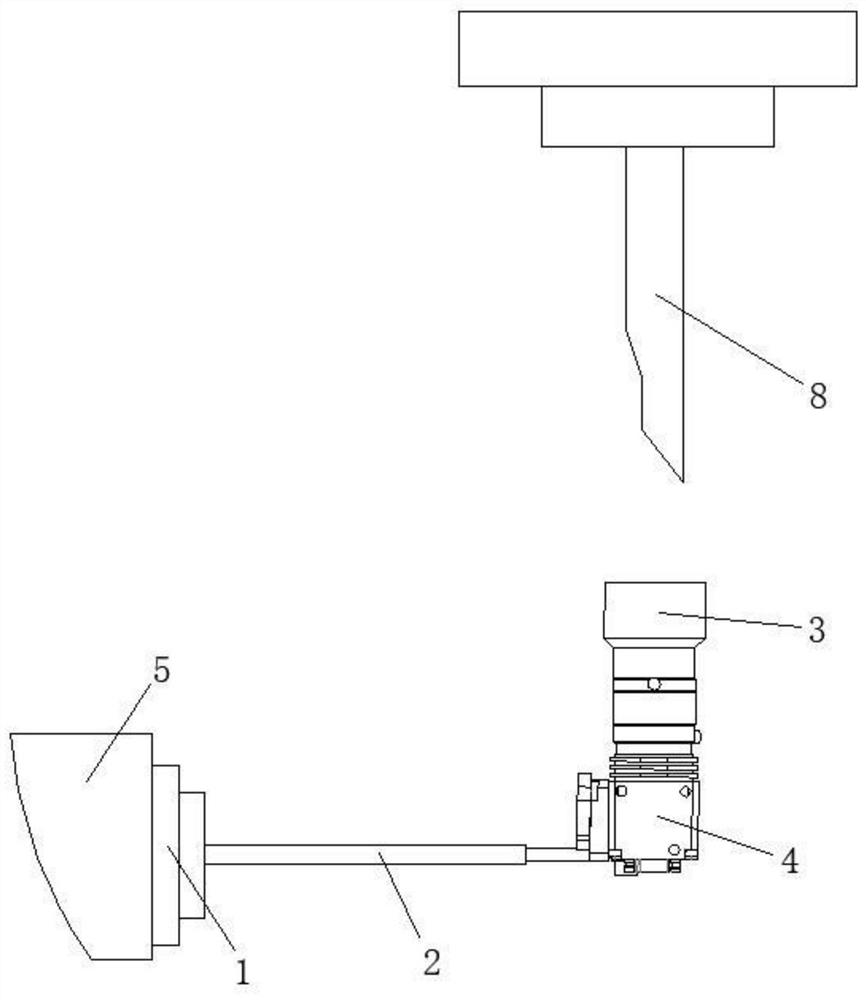

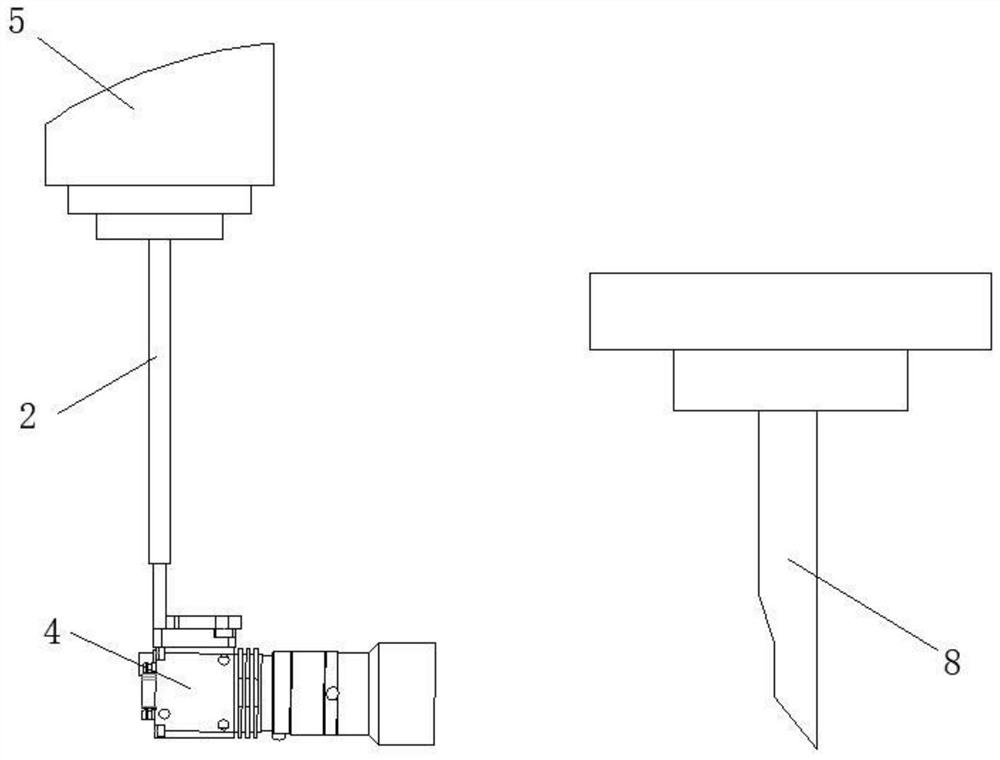

[0028] Embodiment 1: as figure 1 , 2 , 3, a tool real-time detection device and detection method for a machining center, including a collection area 7, the collection area 7 is provided with an in-position detection module and a signal transmission module, the tool 8 is suitable for running to The collection area 7, the in-position detection module includes a soft robotic arm 5, the end of the soft robotic arm 5 is provided with a visual image acquisition system, and the visual image acquisition system is suitable for collecting image information of a tool; The detection device also includes an image processing module 6, and the signal transmission module is suitable for transmitting the information collected by the visual image acquisition system to the image processing module 6; the image processing module 6 includes a damage assessment unit, and the damage The evaluation unit is suitable for comparing and evaluating the image information with preset information; the image ...

Embodiment 2

[0038] Embodiment 2: as figure 2 , 3 As shown, a camera support 2 is also arranged between the connecting piece 1 and the macro camera module 4 .

[0039] Through the setting of the camera support 2, it is convenient to adjust the initial angle of the camera, so as to ensure that the soft robotic arm 5 can accurately direct the shooting direction of the macro camera module 4 towards the specified direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com