Preparation method for heated cigarette tobacco sheet

A technology for tobacco sheets and cigarettes, which is applied in the field of preparation of heated cigarette tobacco sheets, can solve the problems of low tensile strength, easy breakage, breakage, low elongation of reconstituted tobacco leaves, etc., so as to reduce miscellaneous air and improve the original aroma of tobacco. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

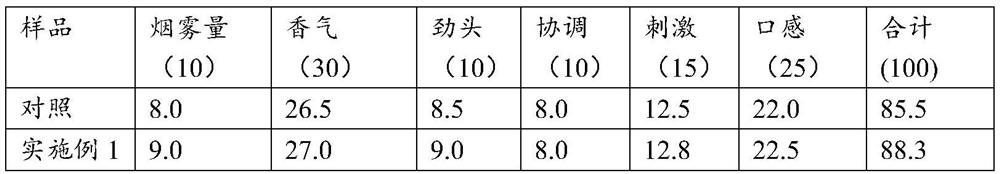

Examples

preparation example Construction

[0032] The preparation method of the heated cigarette tobacco sheet of the present disclosure comprises the following steps:

[0033] Step (1): Prepare a medium containing glucose, peptone, yeast powder and citric acid monohydrate, inoculate Gluconacetobacter sp. ZT-01 with the preservation number CGMCC NO.21544, and culture it for a period of time with constant temperature and shaking , to obtain the seed solution.

[0034] The Gluconacetobacter sp. ZT-01 used in this disclosure is now preserved in the General Microbiology Center (CGMCC) of the China Microbiological Culture Collection Management Committee (CGMCC), the preservation number is CGMCC NO.21544, and the strain name is Gluconic Acid Acetobacter, the strain number is ZT-01, the classification is named Gluconacetobacter sp., the preservation time is December 23, 2020, and the preservation address is No. 3, No. 1, Beichen West Road, Chaoyang District, Beijing. The nicotine concentration that the gluconacetobacter ZT-0...

Embodiment 1

[0059] Pick a single colony of Gluconacetoacetobacter ZT-01 from the slope and inoculate it into 50mL medium (20g / L glucose, 5g / L peptone, 5g / L yeast powder, 1g / L citric acid monohydrate). Constant temperature shaking culture at 30°C for 48 hours to obtain seed solution;

[0060] Dilute the tobacco sheet concentrate with water to 10% mass fraction, and sterilize at 121°C for 15 minutes to obtain a tobacco culture medium;

[0061] The seed liquid is inoculated into the tobacco medium according to the weight ratio of 6%, and the inoculated solution is poured into 75cm 2 In the cell tissue culture bottle, the liquid level height is 2mm, and the culture is kept at a constant temperature for 5 days to grow into a bacterial cellulose film;

[0062] Add (dry weight content) 30% glycerol, 2% spices (tobacco extract: blueberry extract: the mass ratio of phenylethyl alcohol is 7:2:1) to the smoke powder with a particle diameter of 50 μm and mix evenly to obtain smoke powder;

[0063]...

Embodiment 2

[0066] Pick a single colony of Gluconacetoacetobacter ZT-01 from the slope and inoculate it into 50mL medium (20g / L glucose, 5g / L peptone, 5g / L yeast powder, 1g / L citric acid monohydrate). 30°C constant temperature shaking culture for 24 hours to obtain seed solution;

[0067] Dilute the tobacco sheet concentrate with water to a mass fraction of 15%, and sterilize at 121°C for 15 minutes to obtain a tobacco culture medium;

[0068] The seed liquid is inoculated into the tobacco culture medium according to the weight ratio of 15%, and the inoculated solution is poured into a glass tray with a height of 2 mm, and the culture is kept at a constant temperature for 6 days to grow into a bacterial cellulose film;

[0069] In particle diameter, add (dry weight content) 25% smoking agent (glycerol: the volume ratio of propylene glycol is 4:1) in the tobacco powder of 50 μm, the spices of 3% (tobacco extract: the mass ratio of menthol is 8:2) mix evenly to obtain smoke powder;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com