Cement decomposing furnace online simulation system and establishment method thereof

A technology for a cement calciner and a method for establishing it, which is applied in the field of cement production simulation and can solve problems such as the simplification of the working conditions of the calciner model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

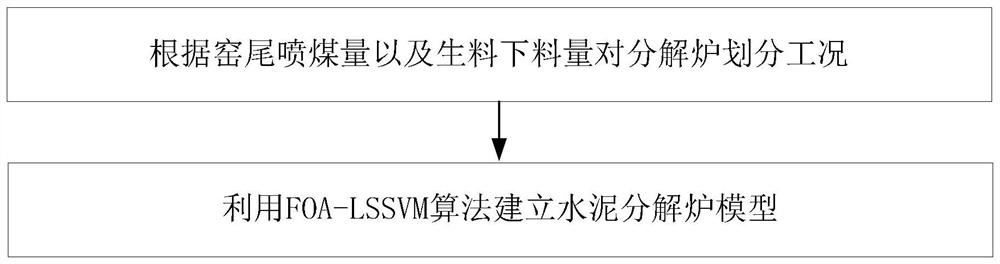

[0093] figure 1 It is a flow chart of a method for establishing a cement decomposition furnace model according to an exemplary embodiment. A method for establishing a cement decomposition furnace model provided by an embodiment of the present invention, the input variables of the cement decomposition furnace model include the tertiary wind pressure of the cement decomposition furnace, the current of the high-temperature fan, the amount of coal injection at the kiln tail and the negative pressure of coal injection, and the output Variables include cement calciner outlet temperature; eg figure 1 As shown, the described establishment method comprises the following steps:

[0094] According to the amount of coal injection at the kiln tail and the amount of raw material cutting, the working conditions of the calciner are divided;

[0095] The cement calciner model was established by using the FOA-LSSVM algorithm.

[0096] As a possible implementation of this embodiment, the divi...

Embodiment 2

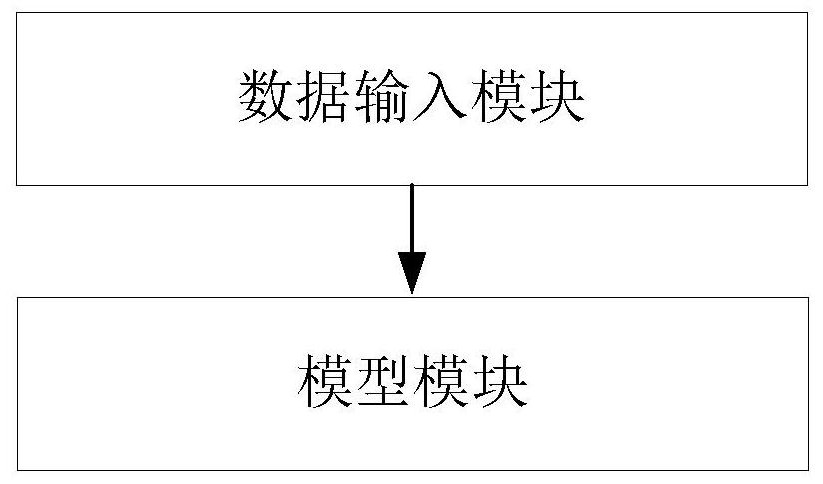

[0146] figure 2 It is a structural diagram of an online simulation system for a cement decomposition furnace according to an exemplary embodiment. Such as figure 2 As shown, an online simulation system of a cement decomposition furnace provided by an embodiment of the present invention includes:

[0147] The data input module is used to input the tertiary air pressure, high temperature fan current, kiln tail coal injection volume and coal injection negative pressure data of the cement decomposition furnace;

[0148] The model module is used to establish the cement decomposition furnace model and output the simulation results according to the input cement decomposition furnace data.

[0149] As a possible implementation of this embodiment, the online simulation system of a cement decomposition furnace also includes:

[0150] The evaluation module is used to evaluate the online simulation of cement decomposition furnace.

Embodiment 3

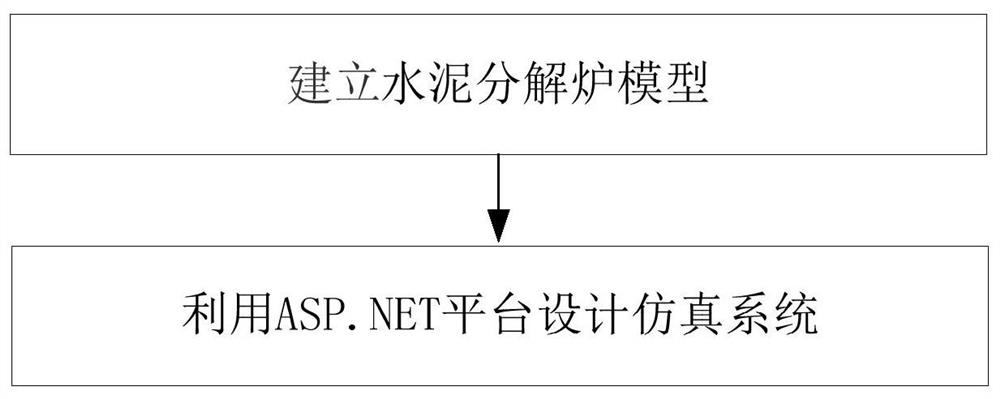

[0152] Such as image 3 As shown, the establishment method of a cement decomposition furnace online simulation system provided by the embodiment of the present invention includes the following steps:

[0153] Adopt the establishment method as mentioned above to set up the cement decomposition furnace model;

[0154] The simulation system is designed by using ASP.NET platform.

[0155] As a possible implementation of this embodiment, the establishment method further includes the following steps:

[0156] Design simulation operation evaluation function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com