Automatic calibration system and method for photoelectric detection target

A photoelectric detection and calibration system technology, applied in the direction of weapon testing, ammunition testing, weapon accessories, etc., can solve the problems of long time consumption, projectile parameter result deviation, error, etc., to shorten the time spent, easy to mass production, reliable The effect of data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

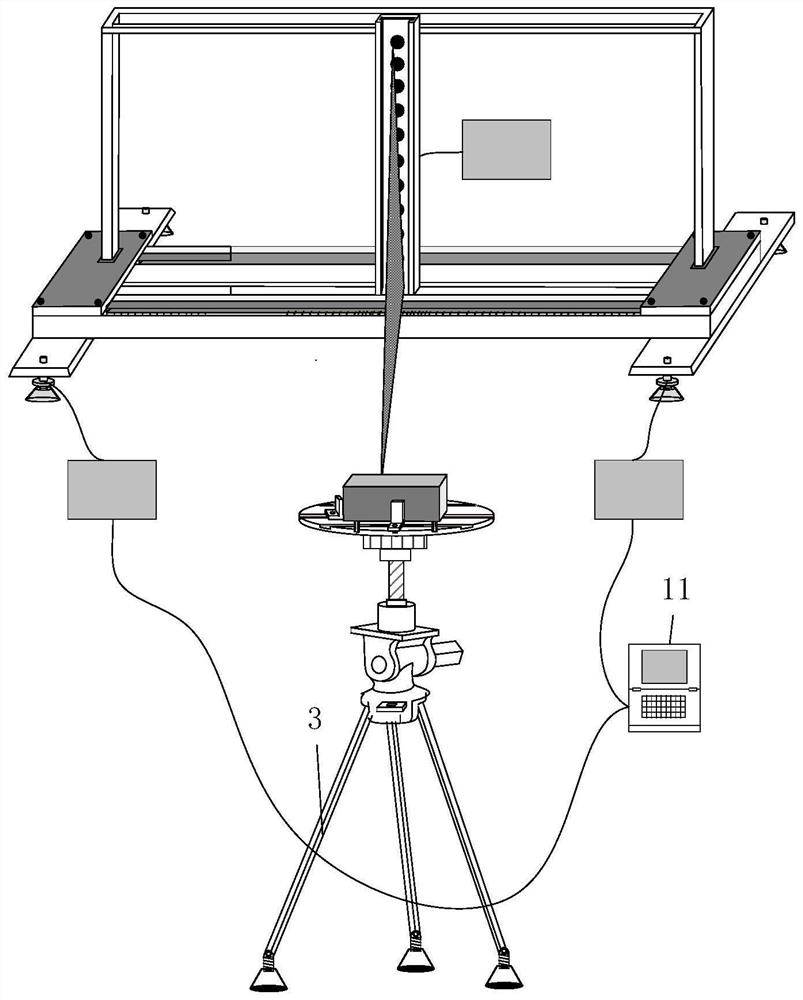

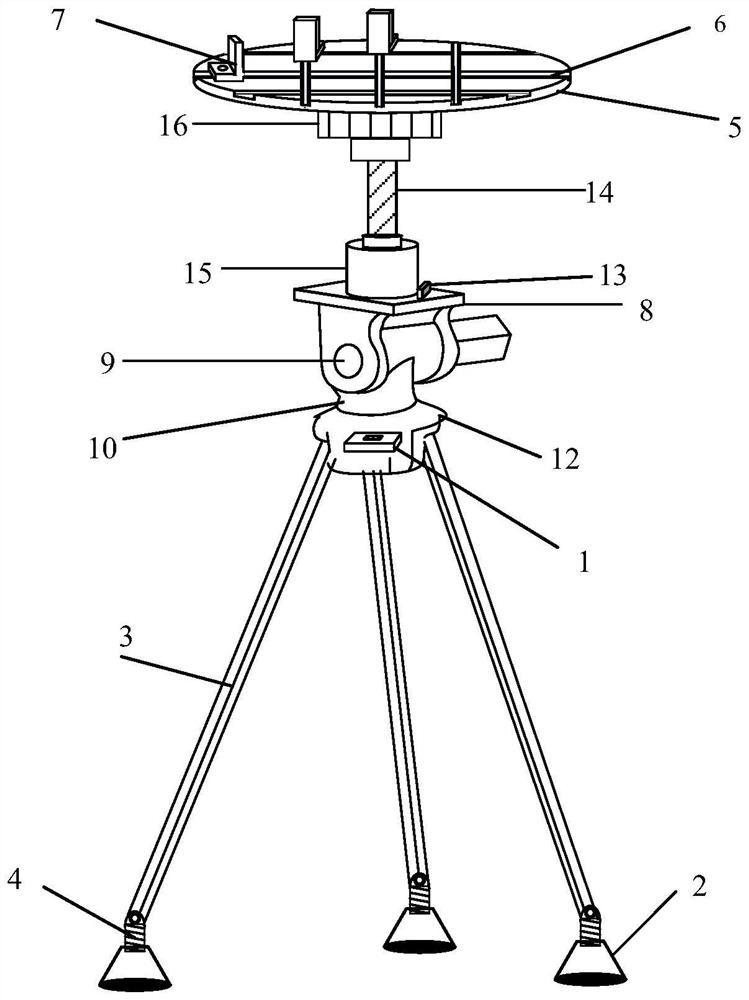

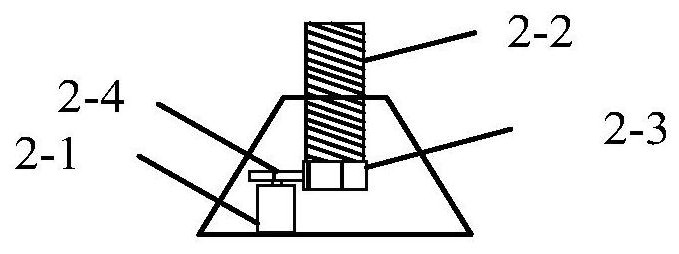

[0040] refer to figure 1 , the automatic calibration system of the photoelectric detection target, including the photoelectric detection target assembly, the signal detection platform, the signal detection platform receives the light curtain generated by the photoelectric detection target assembly, and also includes the measurement control platform and the controller 11;

[0041] The photoelectric detection target assembly is set on the measurement control platform, and the controller 11 controls the measurement control platform to change the height, horizontal angle and pitch angle, thereby changing the position of the photoelectric detection target assembly. When the light curtain signal is received by the signal detection platform at a predetermined position , the controller 11 collects the height, horizontal angle and pitch angle parameters of the measurement and control platform and calculates the included angle parameters according to the horizontal angle information.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com