Cutter head with high rock breaking efficiency for tunnel boring machine

A technology of tunnel boring machine and rock breaking efficiency, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of short service life, affecting the service life of the cutter head, overloading of the cutter, etc., and achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

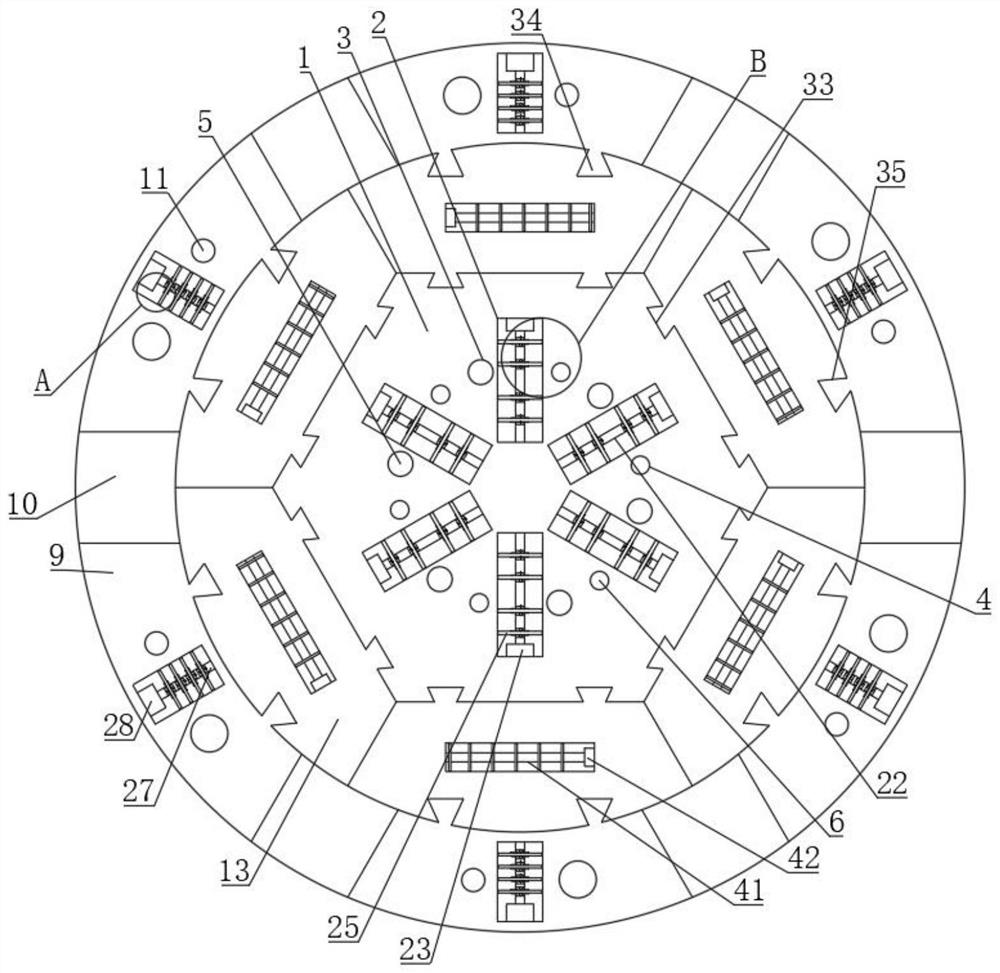

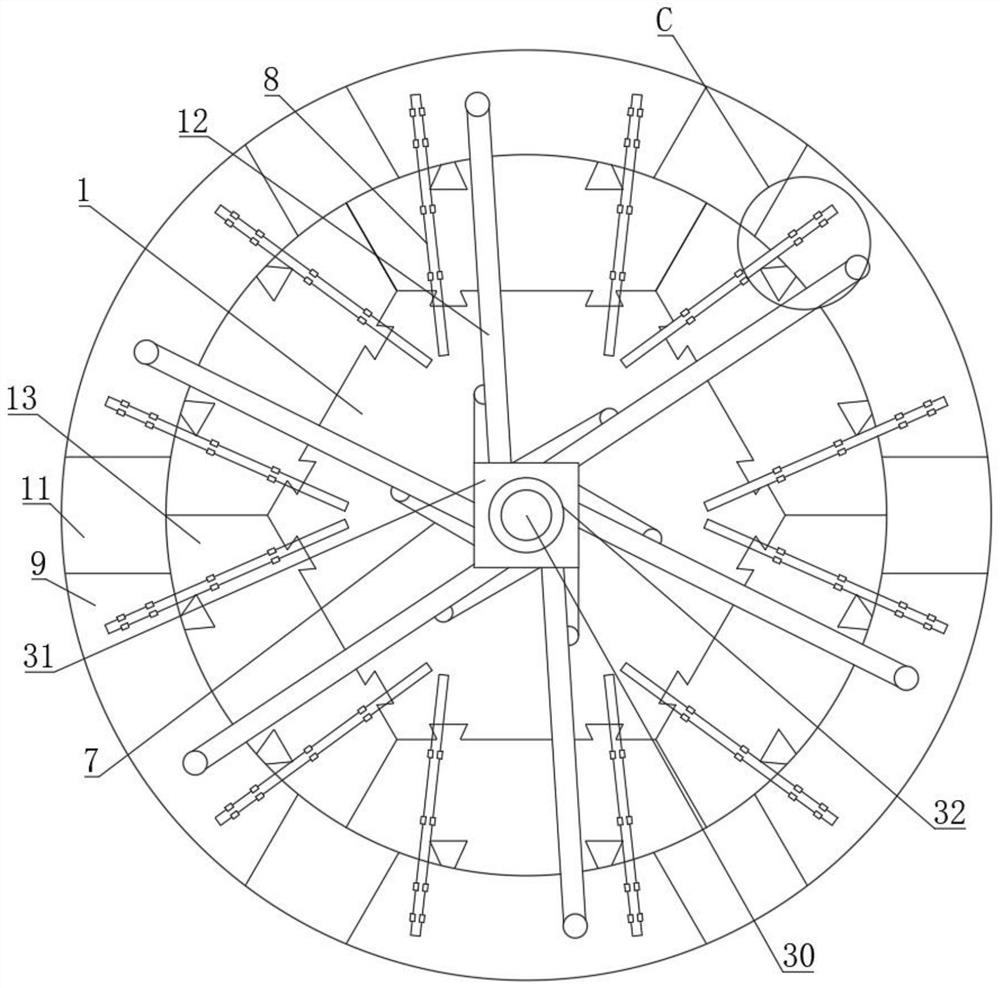

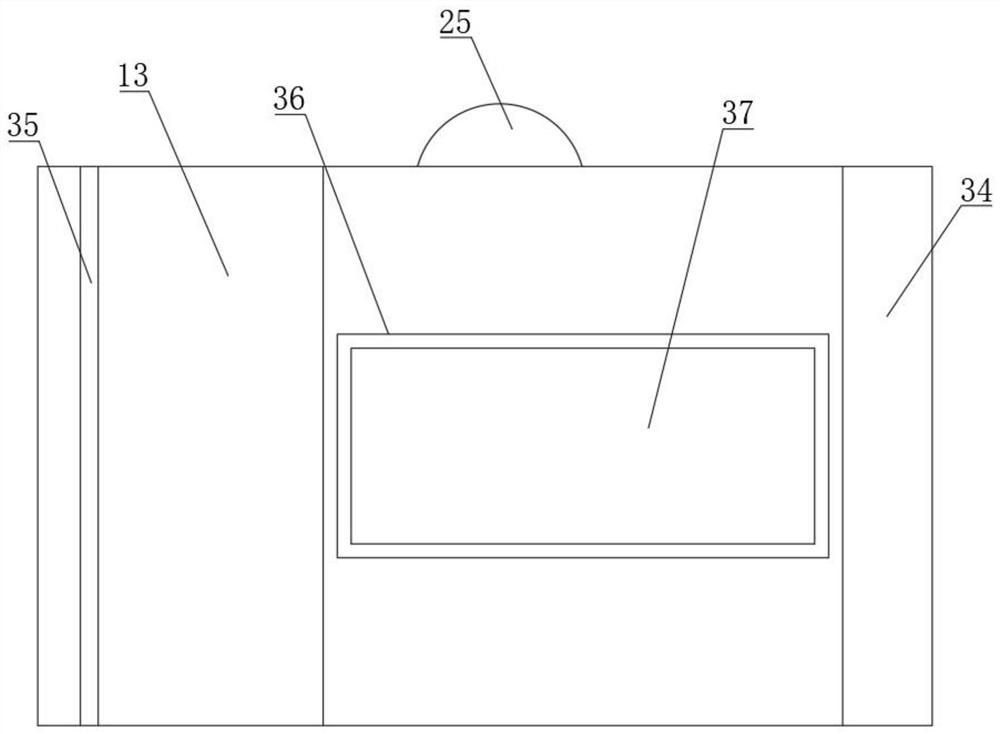

[0023] Example. A cutter head for a tunnel boring machine with high rock-breaking efficiency, which is composed of Figures 1 to 8As shown, the middle block 1 is included, and the upper surface of the middle block 1 is provided with a plurality of circular first hob installation grooves 2 evenly distributed; each first hob installation groove 2 is provided with a first hob assembly, each Both sides of the first hob installation groove 2 are respectively provided with a first installation groove 3 and a second installation groove 4; each first installation groove 3 is equipped with an electron beam generating device, each first installation groove 3 A focusing lens 5 is arranged at the notch; a first high-pressure water nozzle 6 is arranged in each second installation groove 4, and a first high-pressure water pipe 7 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com