Industrial enzyme fermentation device

A fermentation device and industrial technology, applied in the field of high-efficiency industrial enzyme preparation, can solve the problems of difficult removal of maltose, high viscosity and adhesion of maltose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] For example figure 1 -example Figure 6 Shown:

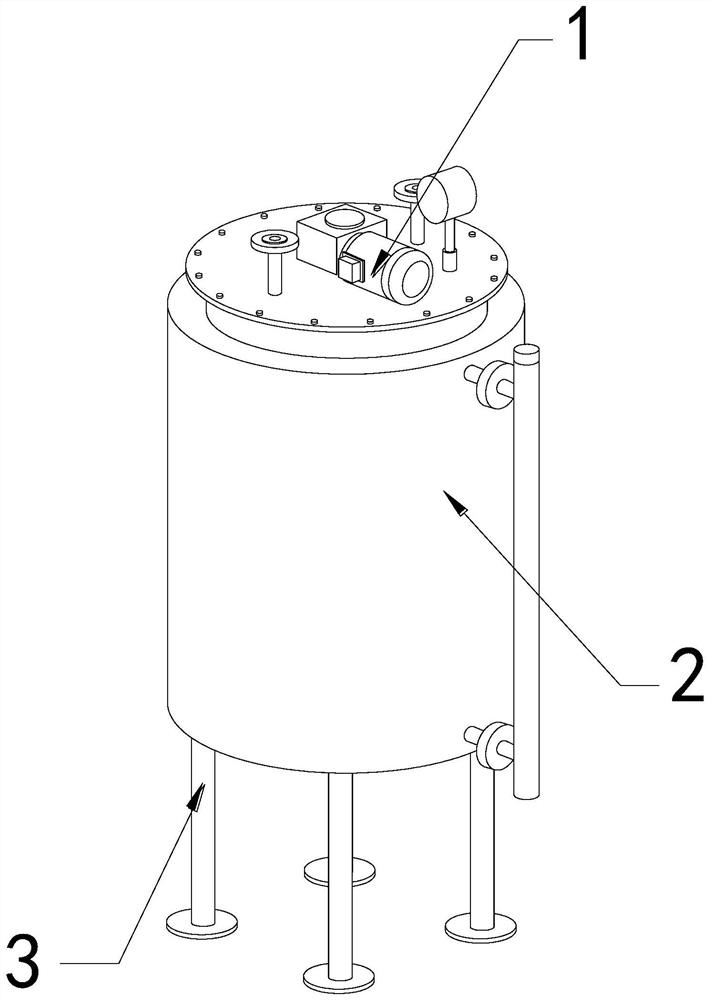

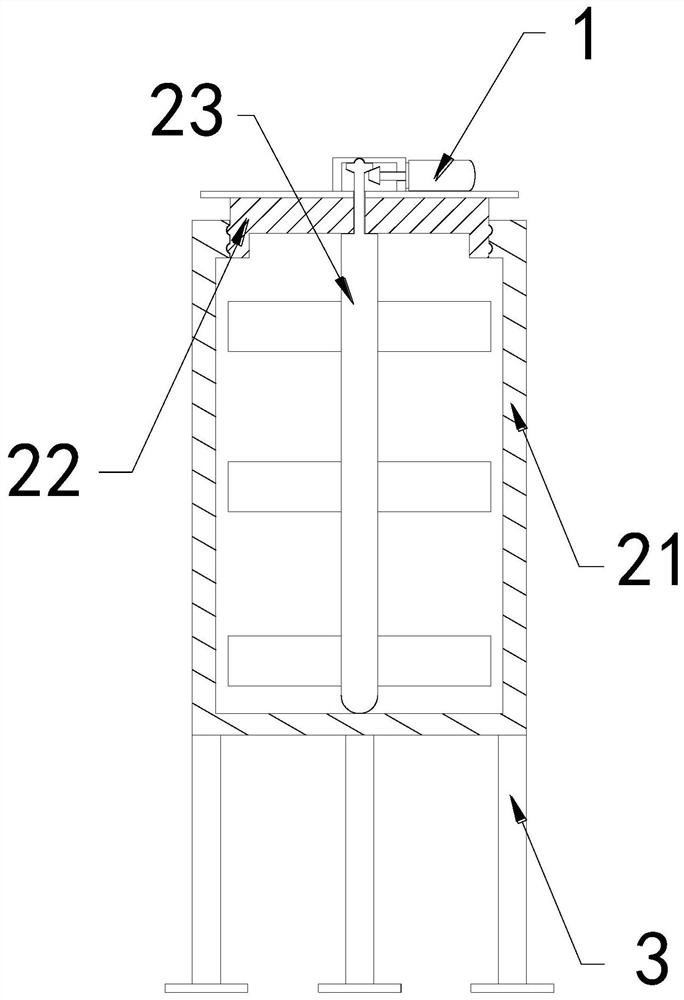

[0030] The invention provides an industrial enzyme fermentation device, the structure of which includes a driver 1, a fermenter 2, and a bracket 3, the driver 1 is installed on the top of the fermenter 2, and the bottom of the fermenter 2 is welded to the upper end of the bracket 3 The fermenter 2 includes an outer frame 21, a top cover 22, and a stirring paddle 23, the top cover 22 is screwed to the upper end of the inner wall of the outer frame 21, and the stirring paddle 23 runs through the top cover 22 internal position.

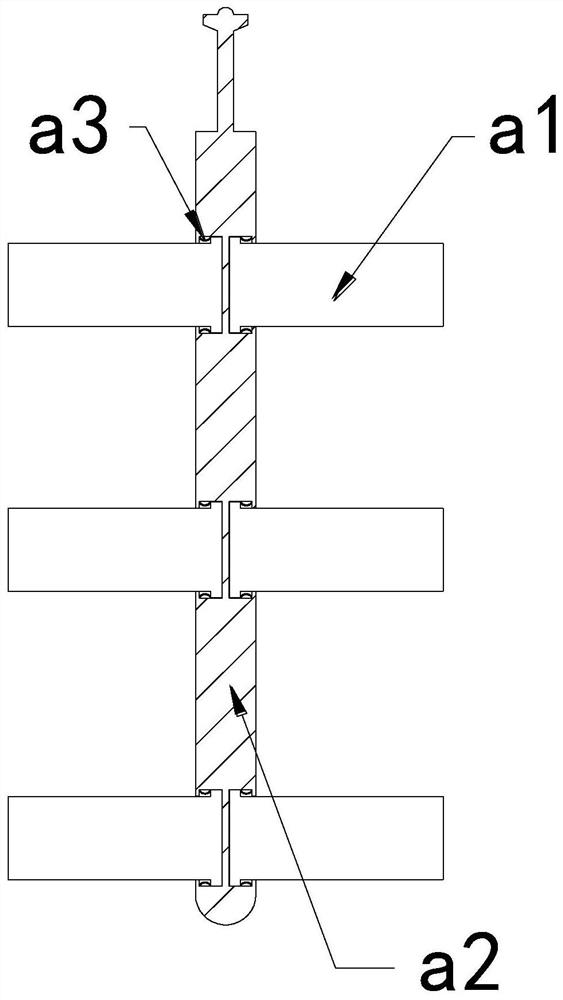

[0031] Wherein, the stirring paddle 23 includes a blade a1, a rotating shaft a2, and an elastic piece a3, the blade a1 is movably engaged with the inside of the rotating shaft a2, and the elastic piece a3 is installed between the inside of the rotating shaft a2 and the blade a1. There are six blades a1, and three are evenly distributed symmetrically on the left and right sides of the rotating shaf...

Embodiment 2

[0037] For example Figure 7 -example Figure 10 Shown:

[0038] Wherein, the middle solid plate b1 includes an upper push plate b11, a linkage rod b12, a bottom connecting plate b13, and an outer elastic piece b14, the bottom of the upper push plate b11 is attached to the top of the linkage rod b12, and the linkage rod b12 The side of the bottom connecting plate b13 is movably engaged with the inner wall of the bottom connecting plate b13. The outer elastic piece b14 is installed between the bottom of the upper push plate b11 and the upper surface of the bottom connecting plate b13. The mechanism shrinks to the extreme to generate vibration, which can make the push up The plate b11 moves up and down under the cooperation of the linkage rod b12 and the outer elastic piece b14, so that the hardened maltose attached to the upper surface of the upper push plate b11 can be vibrated to loosen.

[0039] Wherein, the push-up plate b11 includes a contact plate c1, a reset bar c2, a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com