Plate bending system and plate bending method

A technology of sheet metal and bending device, applied in the field of sheet metal bending, can solve the problems of no bending equipment and low work efficiency, and achieve the effect of improving the efficiency of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

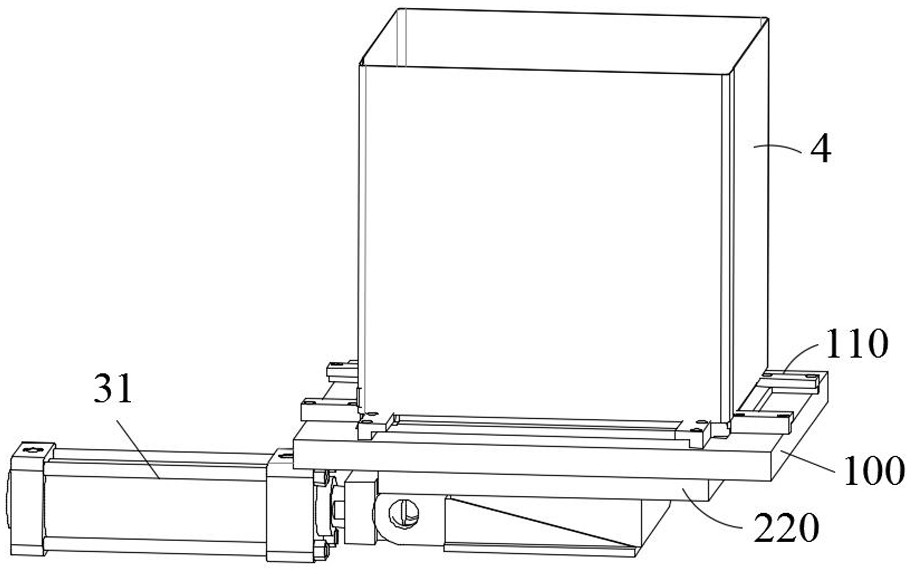

[0043] figure 1 is an exploded view of the plate bending system of the present invention;

[0044] figure 2 It is the overall assembly drawing of the plate bending system of the present invention.

[0045] In this example, if figure 1 , figure 2 As shown, this embodiment provides a plate bending system, which includes: a plate support frame 1, a plate bending device 2 and a driving device 3; wherein the plate bending device 2 is located on the inner ring of the plate support frame 1 The plate 4 is covered on the plate bending device 2, and the bottom of the plate 4 is placed on the plate supporting bracket 1, that is, the driving device 3 is suitable for driving the plate bending device 2 to the bottom four sides of the plate 4 Apply an outward thrust to make the four sides of the bottom of the plate 4 bend outward.

[0046] In this embodiment, the plate 4 is directly covered on the plate bending device 2, and at the same time, the bottom of the plate 4 is supported by ...

Embodiment 2

[0078] On the basis of Embodiment 1, this embodiment provides a sheet bending method, which includes: using the sheet bending system provided in Embodiment 1 to bend the sheet 4; by covering the sheet 4 on the sheet bending device 2, to place the bottom of the plate 4 on the plate supporting bracket 1; drive the plate bending device 2 through the driving device 3 to apply outward thrust to the bottom four sides of the plate 4, so that the bottom four sides of the plate 4 are folded outward bend.

[0079]To sum up, in the present invention, the plate is directly covered on the plate bending device, and at the same time, the bottom of the plate is supported by the plate supporting bracket, and the plate bending device is driven by the driving device to apply outward thrust to the four sides of the bottom of the plate. To achieve the function of bending the plate, it can improve the efficiency of automated production, and overcome the shortcomings of traditional simple tooling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com