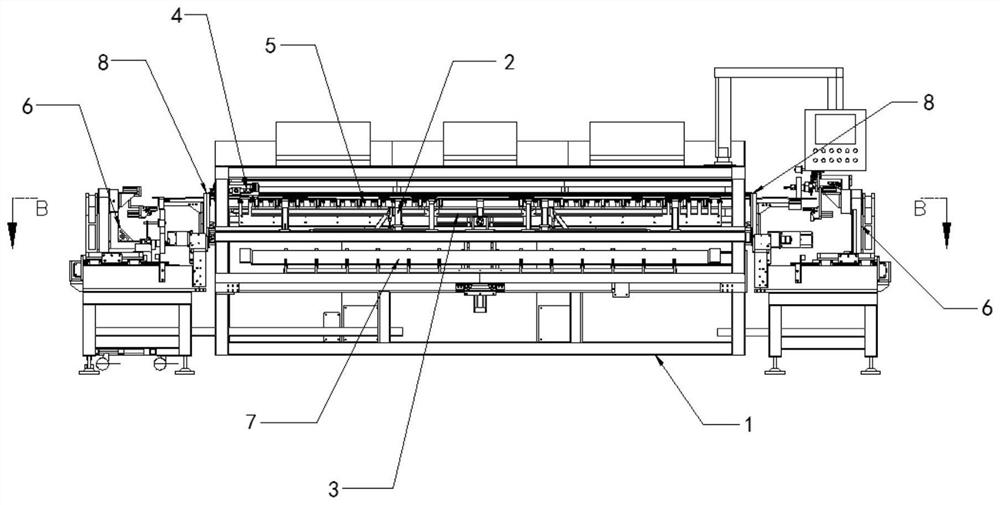

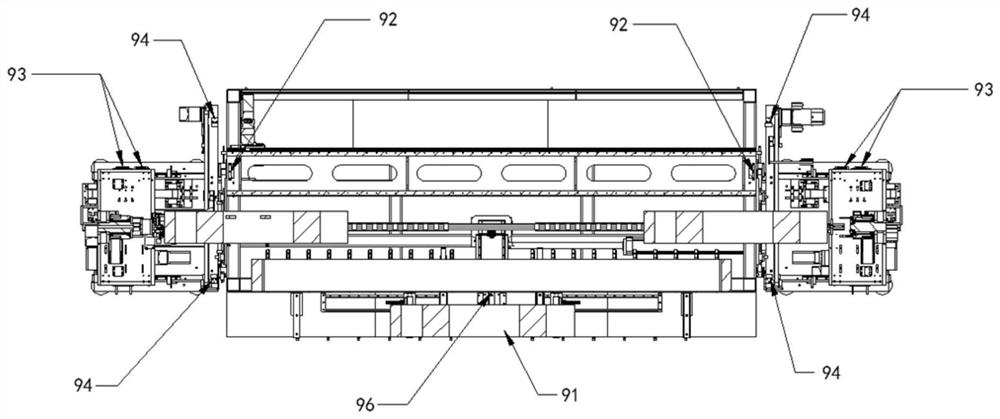

Automatic glue winding machine for plates

A glue wrapping machine, automatic technology, applied in the direction of electrical components, circuits, conductor/cable insulation, etc., to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

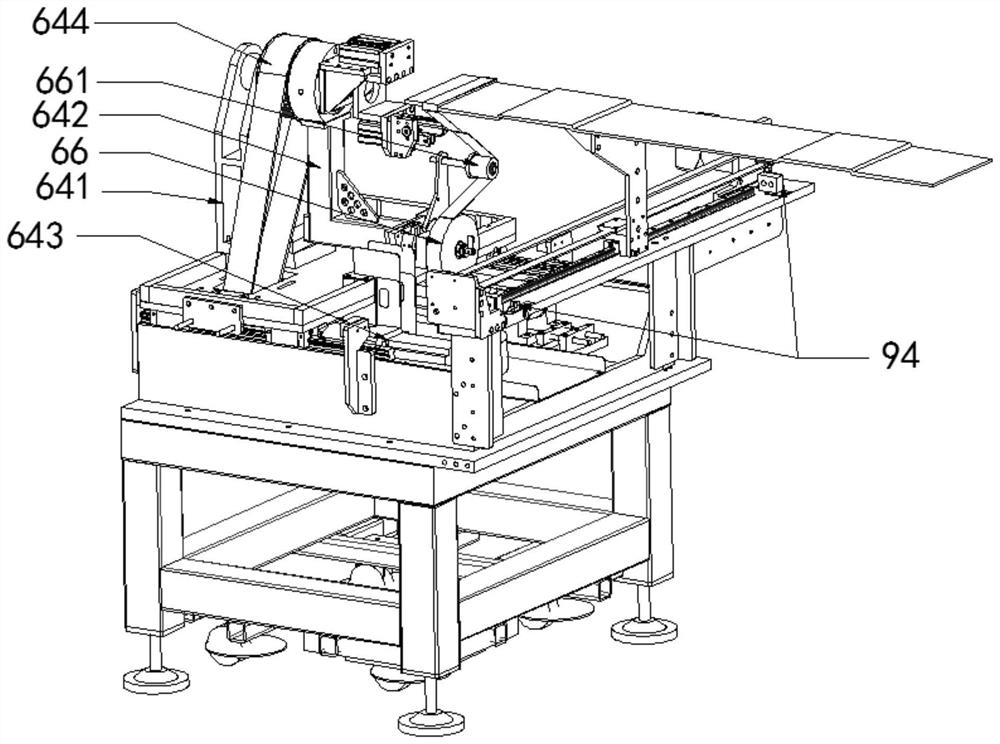

[0058] As an embodiment, the third translation mechanism 33 includes two first slider guide rails 331, two guide rail supports 332 and a third push cylinder 333, and the two guide rail supports 332 are distributed in the middle of the frame 1, The two first slider guide rails 331 are respectively arranged on the two guide rail supports 332 along the y-axis, and the sliders of the guide rail sliders 332 are provided with right-angle seats 334, and the first installation rod 31 is arranged on the two guide rail supports 332. At the top of the right-angle seat 334, the third push cylinder 333 is arranged on the frame 1 and the output end is connected with the first installation rod 31, and the third push cylinder 333 is used to push the first installation rod 31 on the first slider guide rail 331 on the slide.

[0059] like Figure 11 As shown, as an embodiment, the material lifting mechanism 5 includes a second installation rod 51 and a second lifting cylinder 52, the second li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com