Large-area thin film pressure sensor

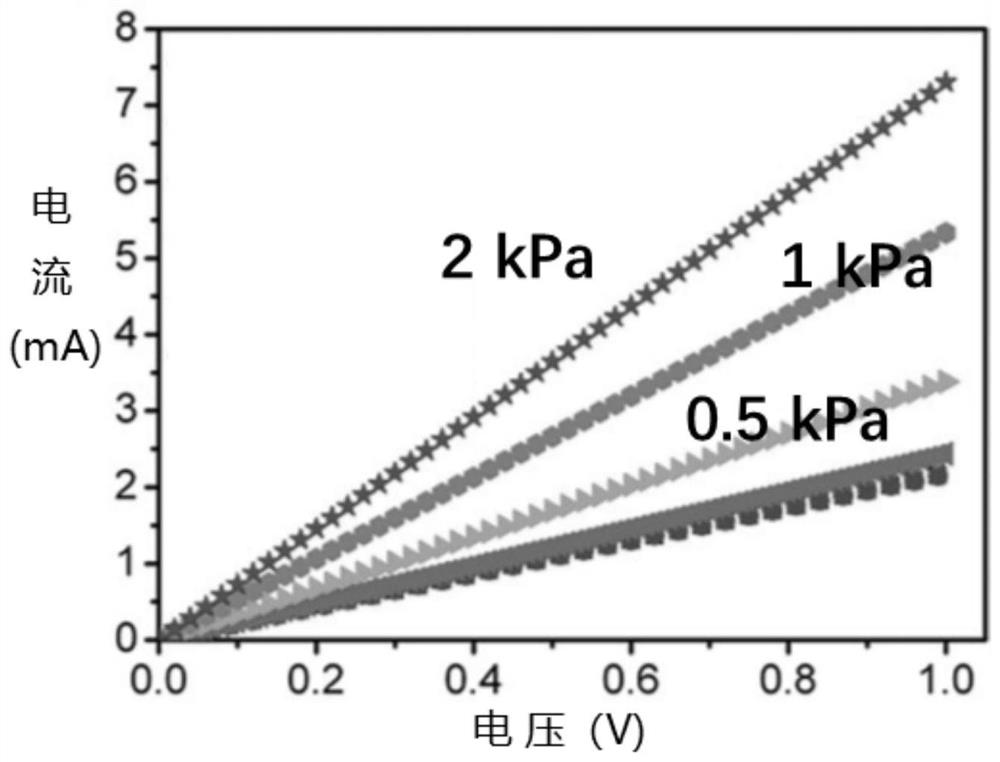

A technology of pressure sensor and large-area thin film, which is applied in the measurement of fluid pressure using piezoelectric devices and the measurement of the property and force of piezoelectric resistance materials, etc. It can solve the problems of poor stability, self-collapse, and poor consistency of output performance of thin-film pressure sensors. and other issues to achieve the effect of improving consistency and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

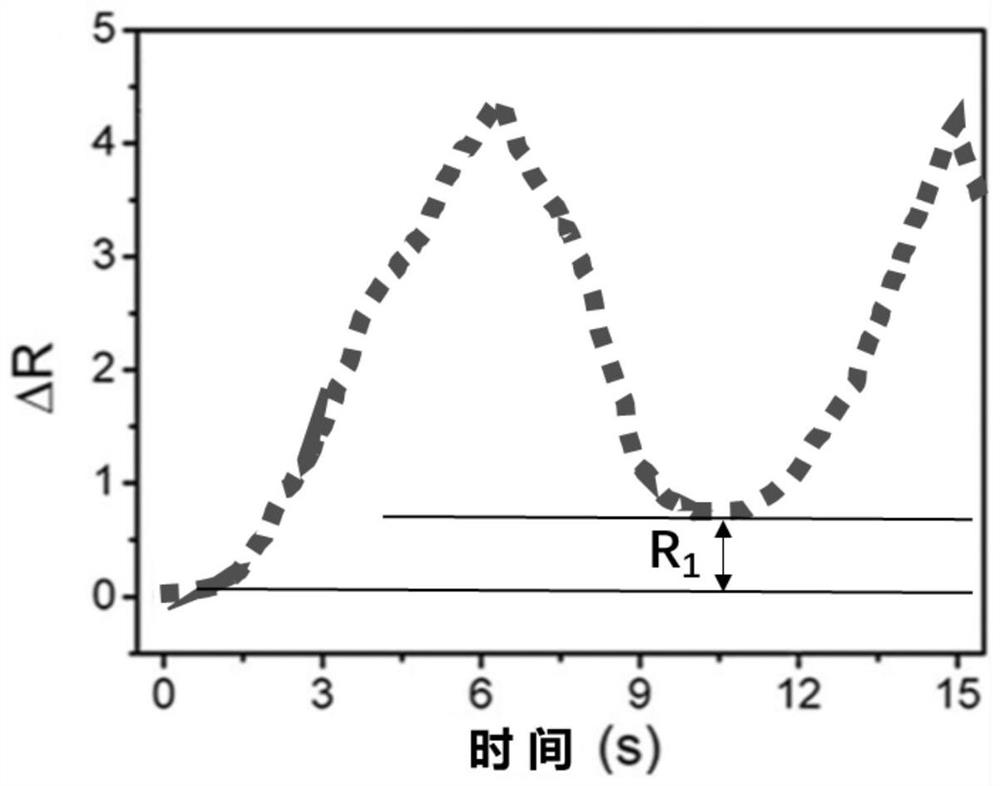

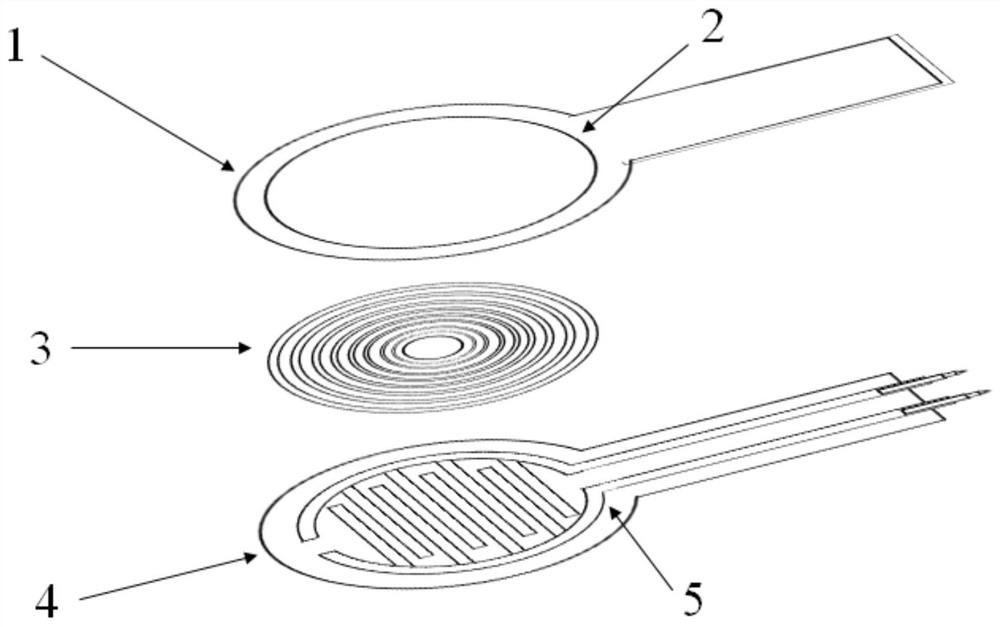

[0031] figure 2 A schematic structural diagram of a large-area thin-film pressure sensor according to an embodiment of the present invention is shown. Such as figure 2 As shown, the large-area thin-film pressure sensor includes an upper encapsulation layer 1 , a lower encapsulation layer 4 , an electrode layer 5 , a nano-sensitive layer 2 and a flexible support layer 3 . The electrode layer 5 is formed on the lower encapsulation layer 4, and the electrode layer 5 is connected to an external power source. The nano-sensitive layer 2 is formed on the upper encapsulation layer 1 in a film form. The flexible support layer 3 is arranged between the nano-sensitive layer 2 and the electrode layer 5, and is configured to allow the nano-sensitive layer 2 and the electrode layer 5 to When the external pressure is removed, the nano-sensitive layer 2 and the electrode layer 5 are completely separated.

[0032] According to the solution of the present invention, by adding a flexible s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com