Backflow assembly of ball screw

A ball screw and assembly technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of shortened travel of recirculating ball screw, extrusion of beads, and many processes of return end cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] For convenience of description, in the following embodiments, the same components are denoted by the same reference numerals.

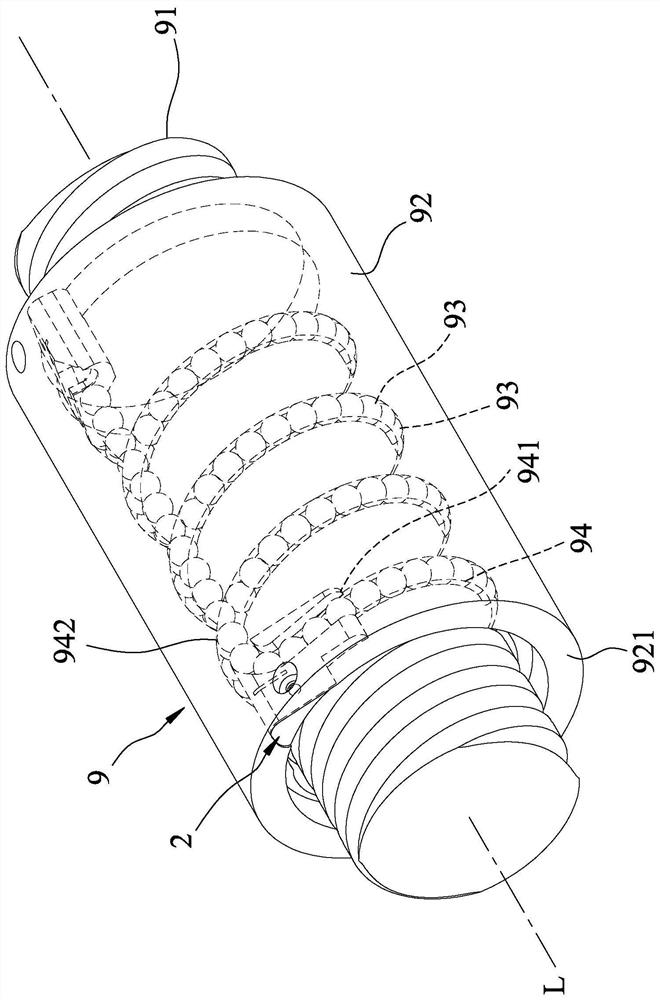

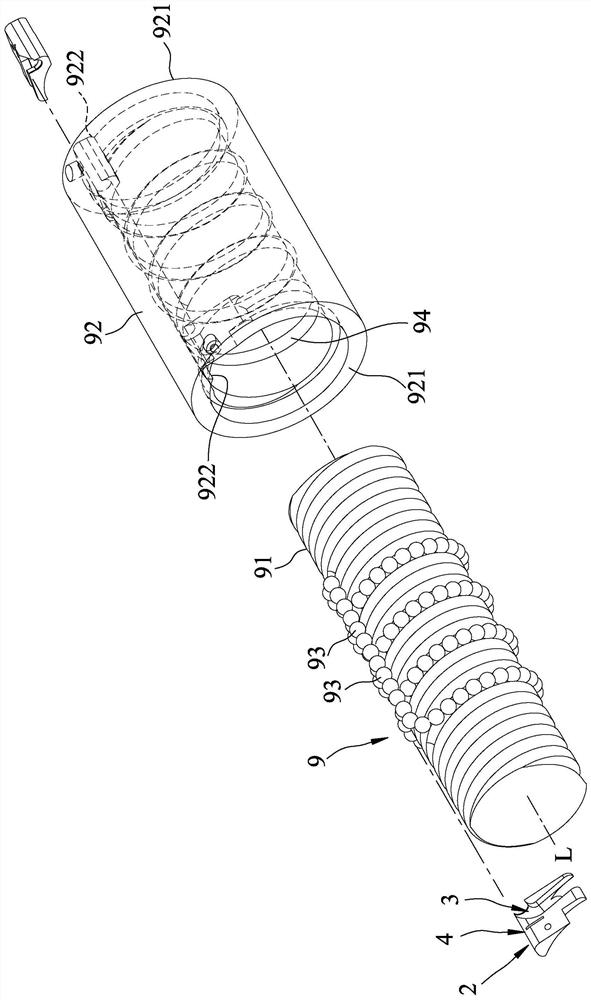

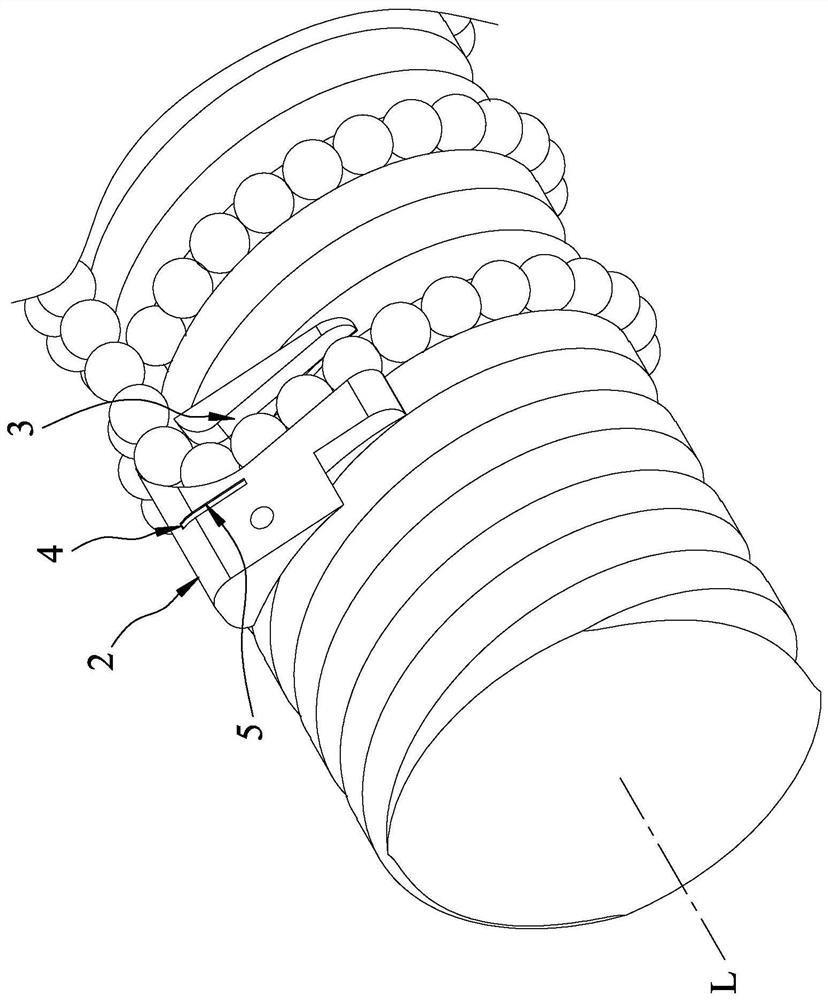

[0030] refer to figure 1 , 2 , 3. The first embodiment of the return assembly of the ball screw of the present invention is applied to the ball screw 9, and the ball screw 9 includes a screw shaft 91 extending along an axis L, and a nut seat 92 surrounding the screw shaft 91 , a plurality of rolling elements 93 that can be cyclically arranged between the screw shaft 91 and the nut seat 92, and a plurality of rolling grooves formed inside the nut seat 92 for the cyclic rolling of the rolling elements 93 94. In this embodiment, the rolling element 93 is a ball, and it can also be a roller or other equivalent elements in other embodiments.

[0031] The nut seat 92 has two oppositely disposed end faces 921 perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com